Straight-down-type slab backlight source

A backlight and direct-lit technology, applied in the field of backlight, can solve the problems of thick thickness, fluctuating with the wind, limited specifications, etc., and achieve the effect of meeting outdoor applications, improving luminous efficiency, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0037] The descriptions of the front side, the rear side, the inside, the outside, and the surroundings in this embodiment are based on the drawings and the positions in the implementation.

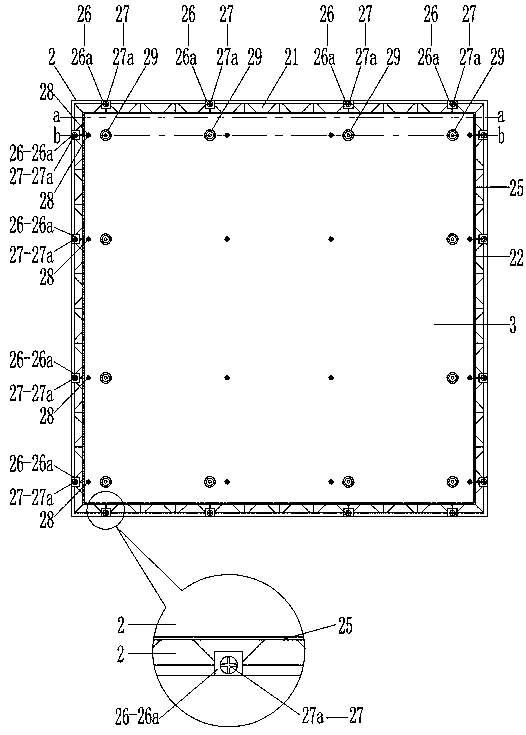

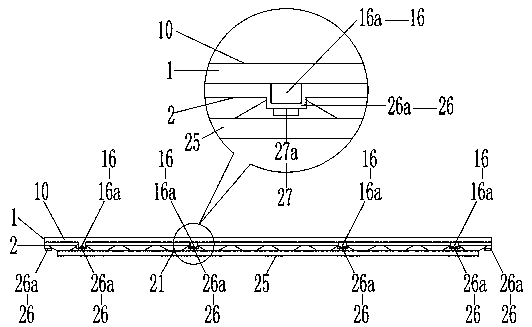

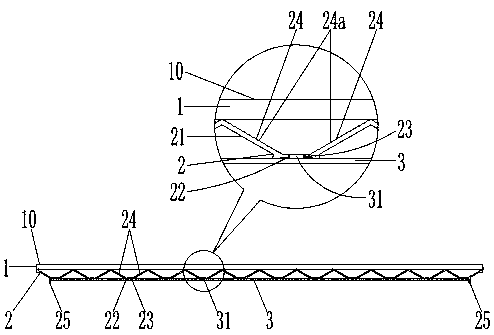

[0038] An embodiment of a direct-type flat panel backlight source in the present invention, such as Figure 1 to Figure 9 As shown, it consists of a plurality of conical cavities (21) that protrude backwards, are connected to each other, and are evenly distributed in an array, and the conical cavities (21) face backwards and the reflectors on the conical top surface 22. Lamp hole 23 and the conical reflector 2 that surrounds the guard edge 25 integrally formed on the reflector on the lamp hole 23 periphery on all reflectors; is installed on the conical reflector 2 front side diffusion plate 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com