Ceramic glaze drying device

A drying device and a technology for ceramic glaze, applied in the field of ceramic machinery, can solve the problems of difficult dispersion, unsatisfactory drying effect, and easy accumulation of ceramic glaze, so as to achieve rapid drying, increase volatilization, and avoid accumulation and agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

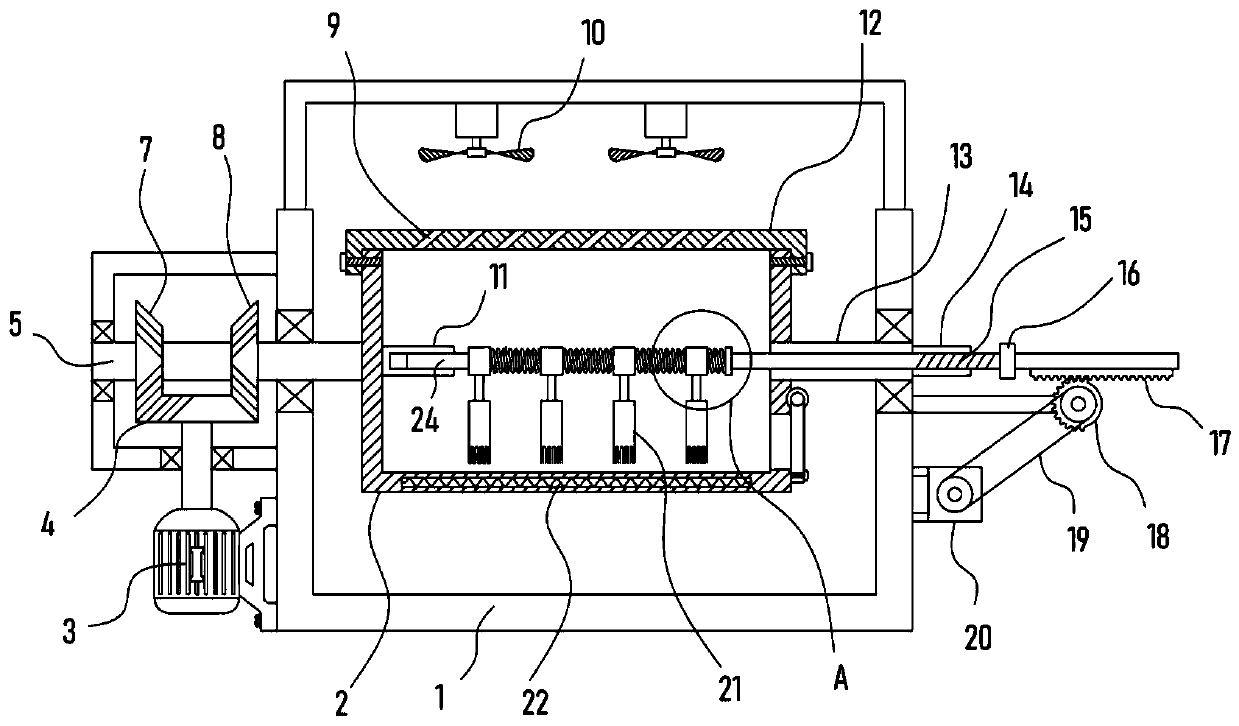

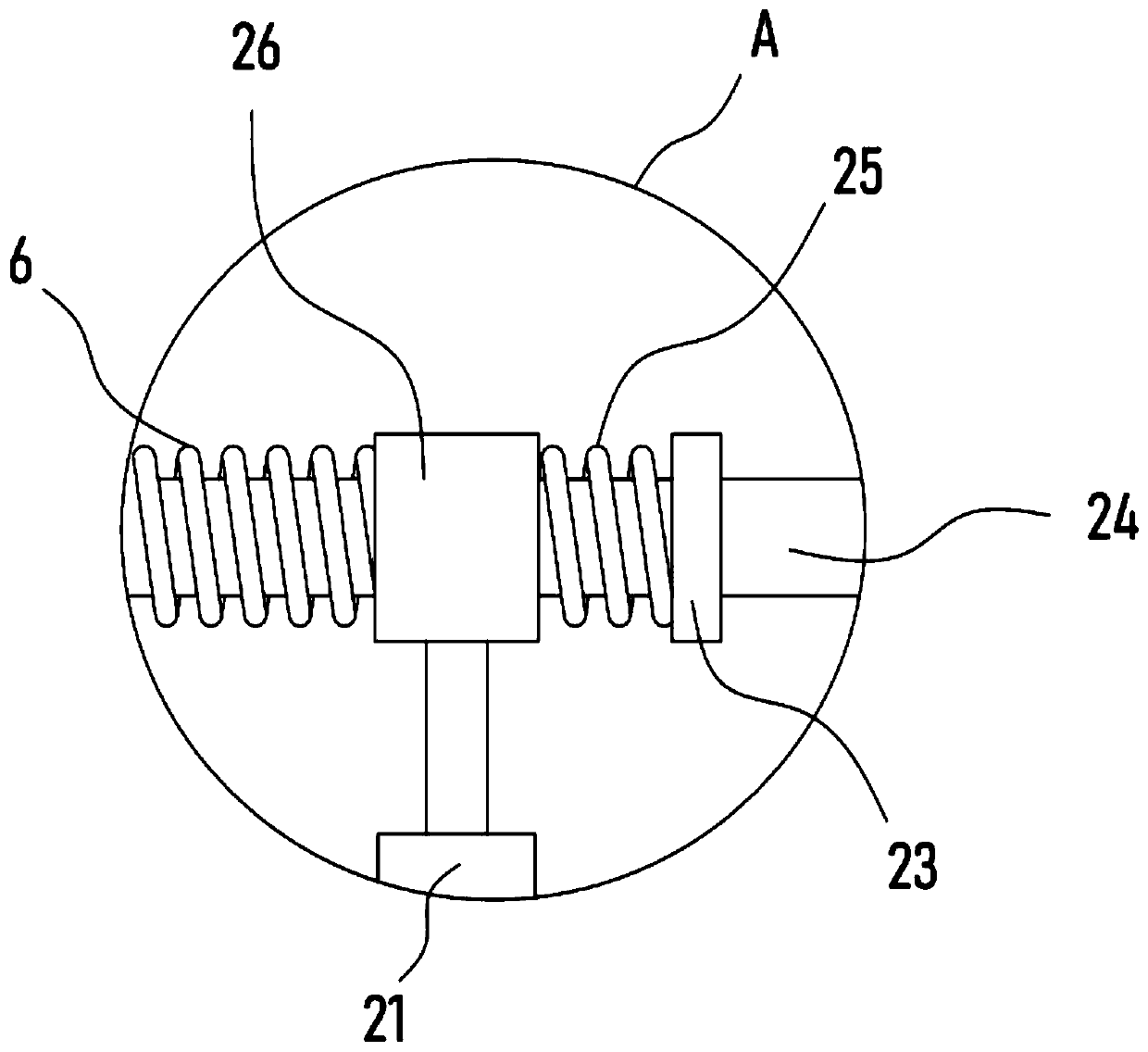

[0022] see Figure 1-3 , a ceramic glaze drying device, comprising a support frame 1, a drying cylinder 2 is installed on the support frame 1, a heater 22 is embedded and fixed at the bottom of the drying cylinder 2, and the two sides of the drying cylinder 2 are respectively the same The axis is fixed with the drive shaft 5 pivotally connected with the support frame 1 and the limit sleeve 13. The drive shaft 5 is connected with an intermittent mechanism driven by the motor I3. The rotating shaft 24 is connected with a dispersion mechanism on the rotating shaft 24, and a cover plate 12 is detachably installed on the top of the drying cylinder 2.

[0023] The provided drying cylinder 2 is used to hold the ceramic glaze to be dried, and the cover plate 12 is used to perform dust-proof treatment on the drying cylinder 2 to prevent dust and sundries from falling into the drying cylinder 2 . The heater 22 heats the drying cylinder 2 to realize the temperature rise inside the dryin...

Embodiment 2

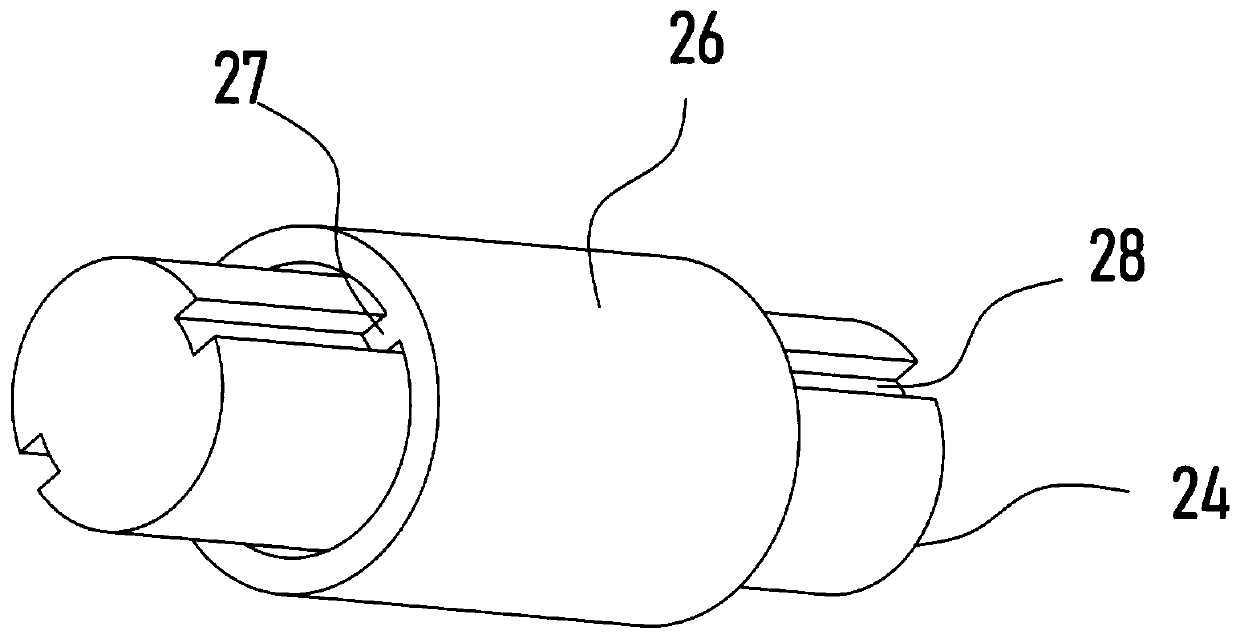

[0028] In order to further improve the water distribution efficiency of the ceramic glaze and improve the drying effect, on the basis of Embodiment 1, the drive mechanism includes a toothed rack 17 and an incomplete gear 18 for meshing transmission. The rack 17 is fixed with a connecting block 16 and a rotating shaft 24. Pivoted on the connecting block 16, the rotating shaft 24 is sleeved with a threaded pipe 14 fixed outside the support frame 1, and the surface of the rotating shaft 24 is tapped with an external thread 15 adapted to the internal thread of the threaded pipe 14. The driving mechanism also includes a motor II20 , the output shaft of the motor II20 is rotationally connected with the incomplete gear 18 through the pulley mechanism 19 .

[0029] The incomplete gear 18 drives the rotating shaft 24 to produce a lateral displacement through the rack 17 meshing with it, and the external thread 15 on the rotating shaft 24 and the internal thread of the threaded pipe 14 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap