Spherical porous lithium titanate/titanium dioxide composite material as well as preparation method and application of composite material

A technology of titanium dioxide and porous lithium titanate, applied in electrode manufacturing, electrical components, battery electrodes, etc., to achieve high specific capacity, simple preparation method, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

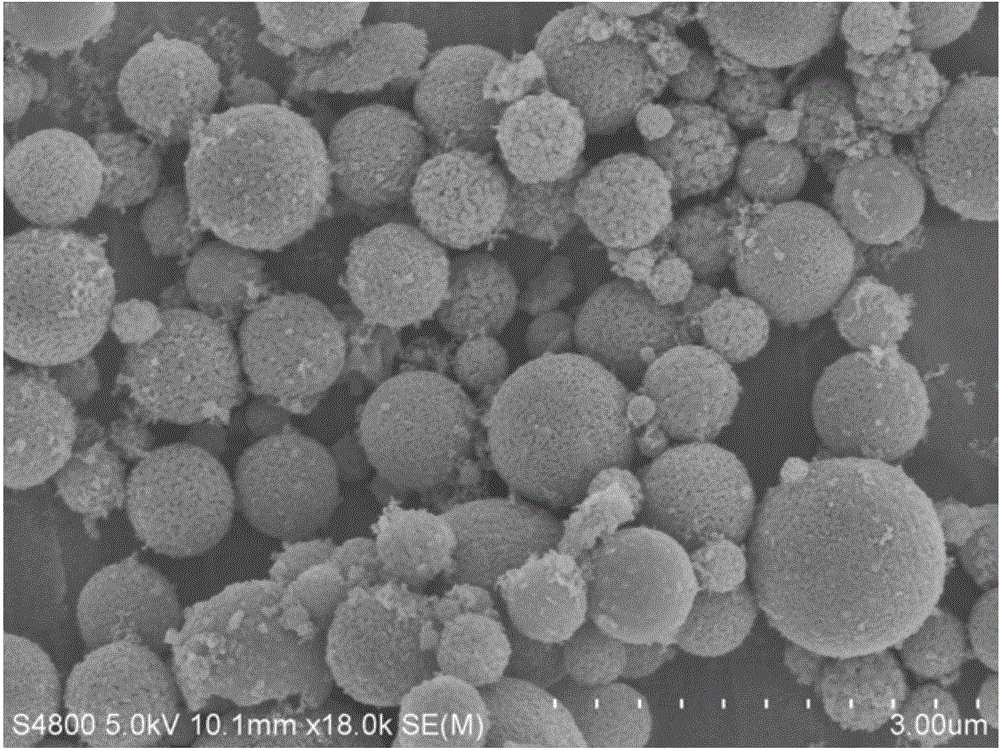

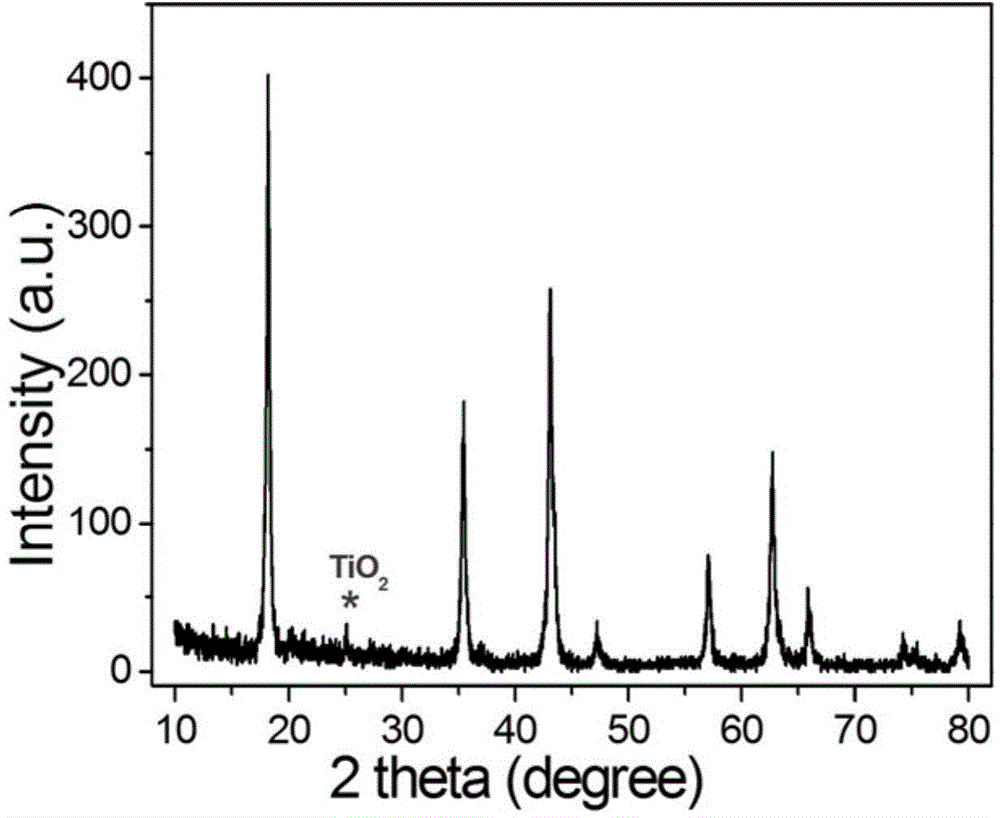

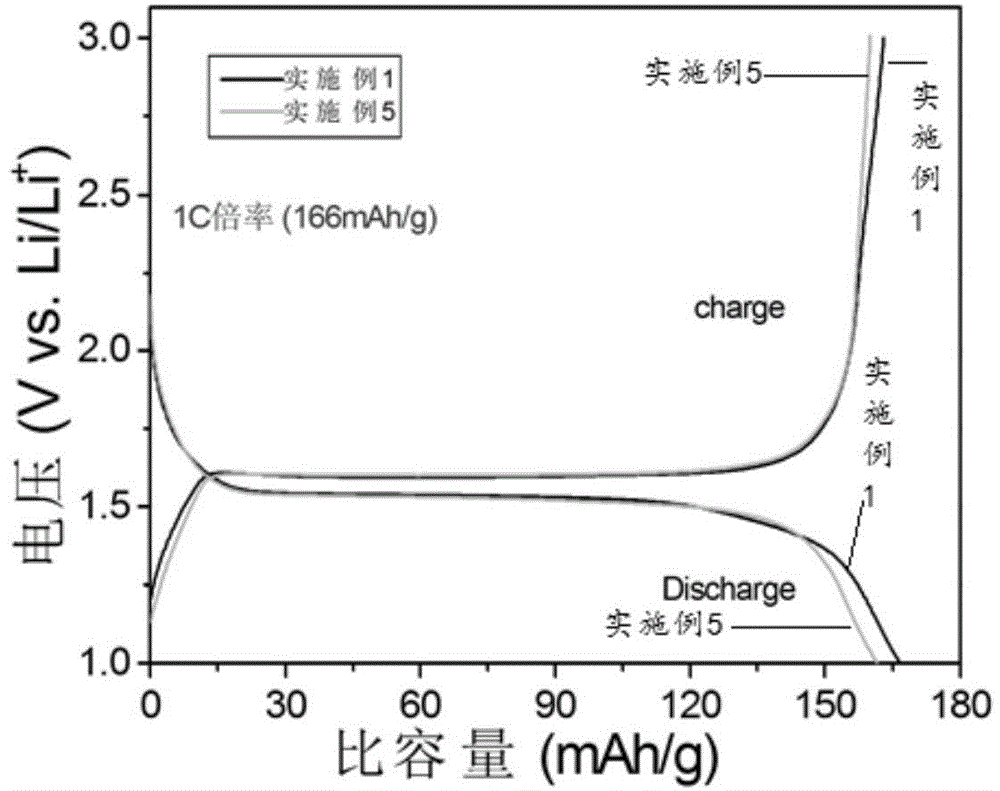

[0024] A spherical porous lithium titanate / titanium dioxide composite material is a spherical porous structure with a size of 0.2-1 micron and a pore diameter of 15-20 nanometers.

[0025] A preparation method of a spherical porous lithium titanate / titanium dioxide composite material, comprising the following steps:

[0026] (1), weigh 0.1544 grams of LiNO 3 and 0.25 g of P123 were dissolved in 20 mL of ethanol solution, and then 0.5 mL of glacial acetic acid solution and 1 mL of tetrabutyl titanate (TBOT) solution were added to the resulting solution, and mixed evenly under ultrasonication;

[0027] (2) Atomize the mixed solution of reactants obtained in step (1) in an atomizer, and at the same time, in a vacuum atmosphere, under the drainage of a vacuum pump, the mist is introduced into a high-temperature furnace through a glass conduit, and passed through a high-temperature furnace at 480 ° C. Dry and decompose to obtain a solid product that is a spherical precursor;

[0...

Embodiment 2

[0031] A spherical porous lithium titanate / titanium dioxide composite material is a spherical porous structure with a size of 0.2-1 micron and a pore diameter of 15-20 nanometers.

[0032] A preparation method of a spherical porous lithium titanate / titanium dioxide composite material, comprising the following steps:

[0033] (1), weigh 0.0193 grams of LiNO 3 Dissolve 0.032 g of F127 in 20 mL of ethanol solution, then add 0.5 mL of glacial acetic acid solution and 0.9 mL of TBOT solution to the resulting solution, and mix well under ultrasonic;

[0034] (2), atomize the solution obtained in step (1) with an atomizer, dry and decompose it in a high-temperature furnace (furnace temperature 480° C.), and finally collect powder particles;

[0035] (3) Calcining the collected powder in air at 600° C. for 8 hours with a heating rate of 5° C. / min.

[0036] An application of a spherical porous lithium titanate / titanium dioxide composite material as an electrode material.

Embodiment 3

[0038] A spherical porous lithium titanate / titanium dioxide composite material is a spherical porous structure with a size of 0.2-1 micron and a pore diameter of 15-20 nanometers.

[0039] A preparation method of a spherical porous lithium titanate / titanium dioxide composite material, comprising the following steps:

[0040] (1), weigh 0.0965 grams of LiNO 3 Dissolve 0.10 g of P123 in 20 mL of ethanol solution, then add 0.5 mL of glacial acetic acid solution and 1 mL of TBOT solution to the resulting solution, and mix well under ultrasonication;

[0041] (2), atomize the solution obtained in step (1) with an atomizer, dry and decompose it in a high-temperature furnace (furnace temperature 480° C.), and finally collect powder particles;

[0042] (3) Calcining the collected powder in air at 600° C. for 8 hours with a heating rate of 5° C. / min.

[0043] An application of a spherical porous lithium titanate / titanium dioxide composite material as an electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com