Optical fiber sensor embedded in prefabricated structure

A fiber optic sensor and prefabricated structure technology, applied in the field of sensors, can solve the problems of short fiber life, different sensors, and non-adjustable fiber prestress, and achieve the effects of controllable service life, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

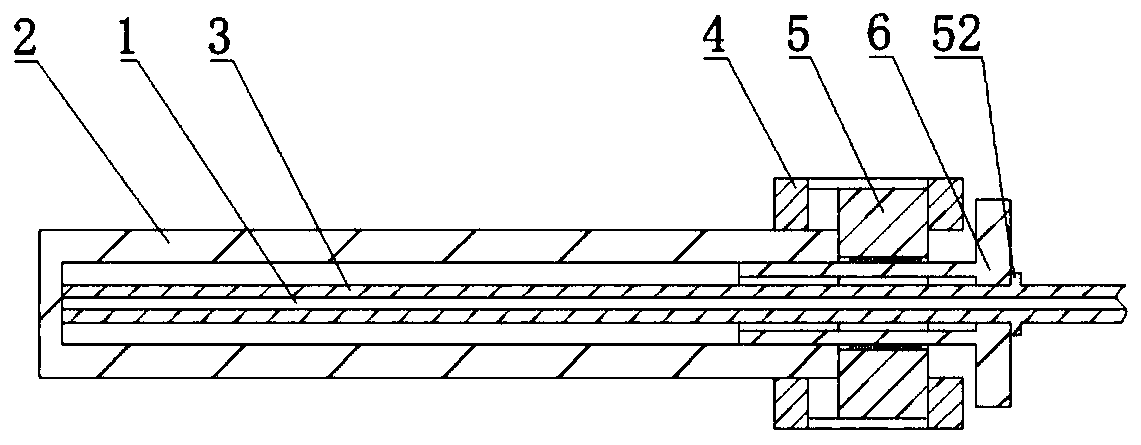

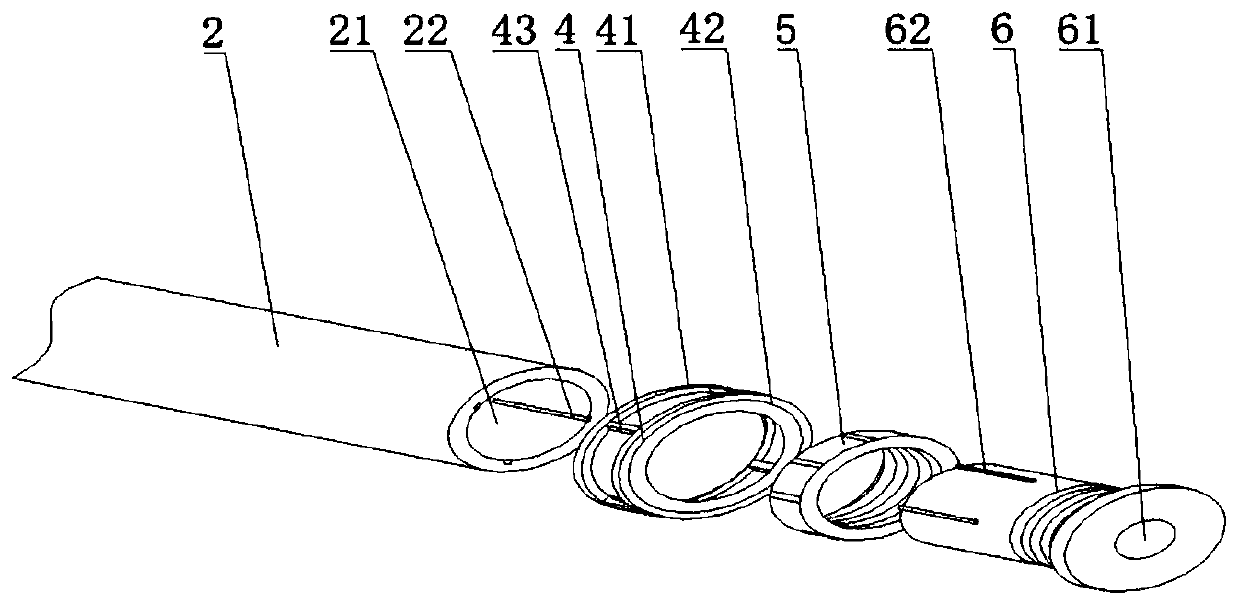

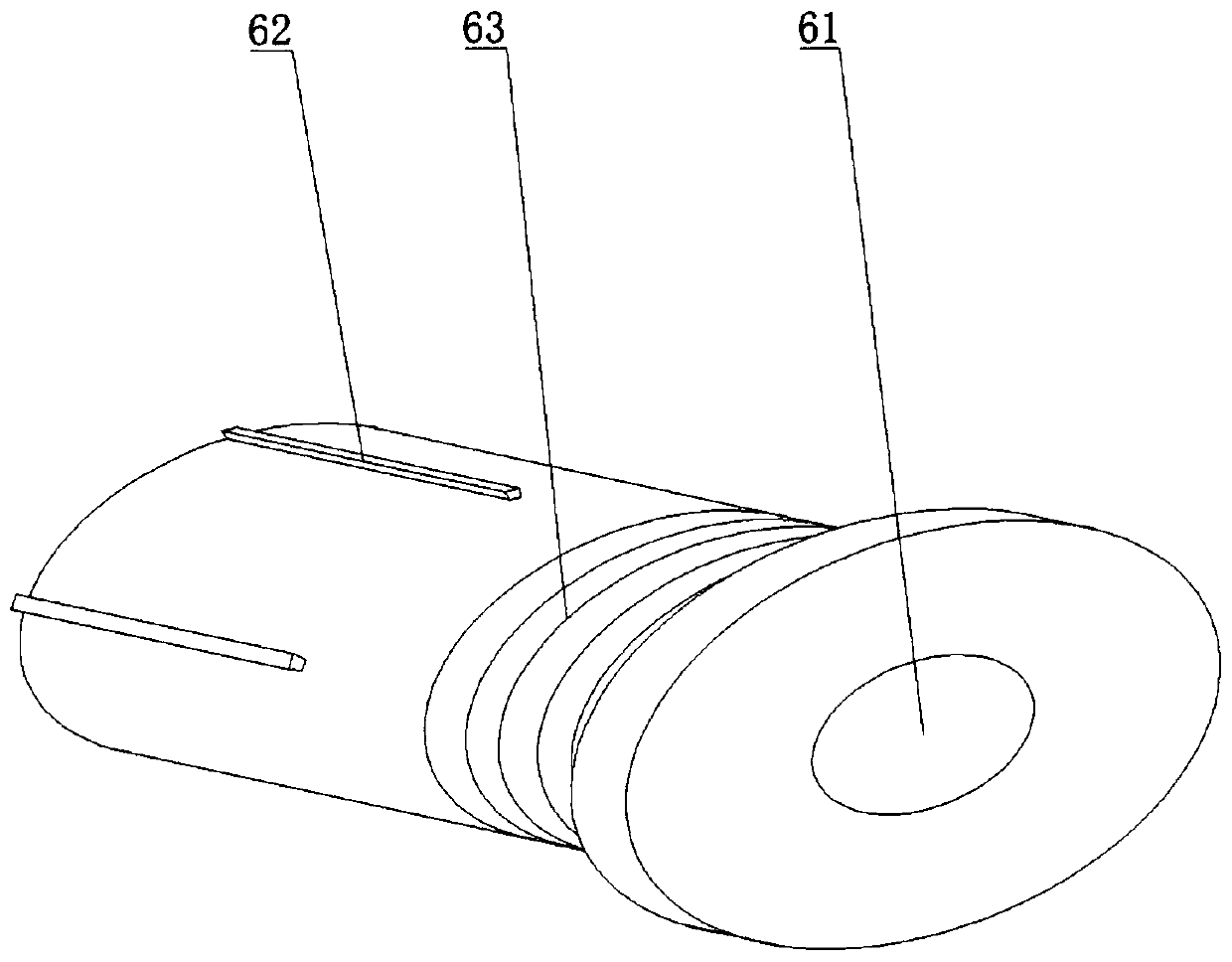

[0021] Example: as attached Figure 1-5 As shown, a fiber sensor pre-embedded in a prefabricated structure includes a detection fiber 1 and a casing 2, the detection fiber is wrapped with a protective layer 3, the casing 2 is hollow inside, and one end of the casing 2 is provided with an opening 21, characterized in that: one end of the detection optical fiber 1 is located in the housing 2 and fixedly connected to the housing 2, the other end of the detection optical fiber 1 passes through the housing 2 through the opening 21, the The opening 21 is provided with an adjustment device, the adjustment device includes a fixed ring 4, an adjustment knob 5 and a push-pull rod 6, one end of the fixed ring 4 is sleeved on the outer shell 2, and is fixedly connected with the outer shell 2, so One end of the push-pull rod 6 is slidably connected with the opening 21, the adjustment knob 5 is sleeved in the fixed ring 4, the adjustment knob 5 is threaded with the push-pull rod 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com