Deep cement soil slurry sampling device and method

A sampling device and cement-soil technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of unable to sample and analyze cement-soil slurry, and having no instruments and methods for sampling deep-layer cement-soil slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

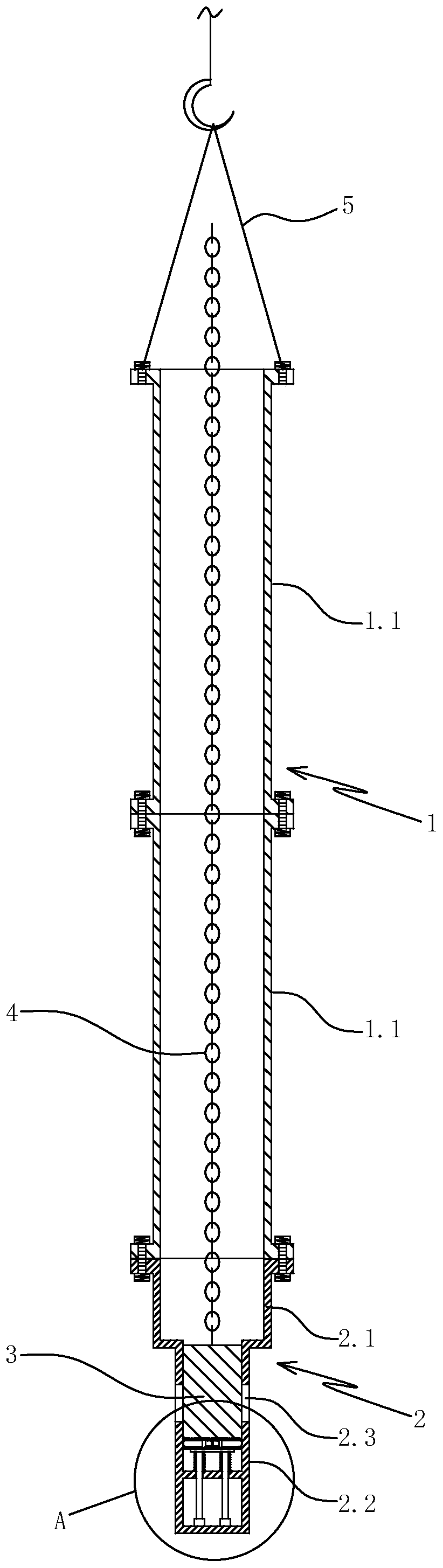

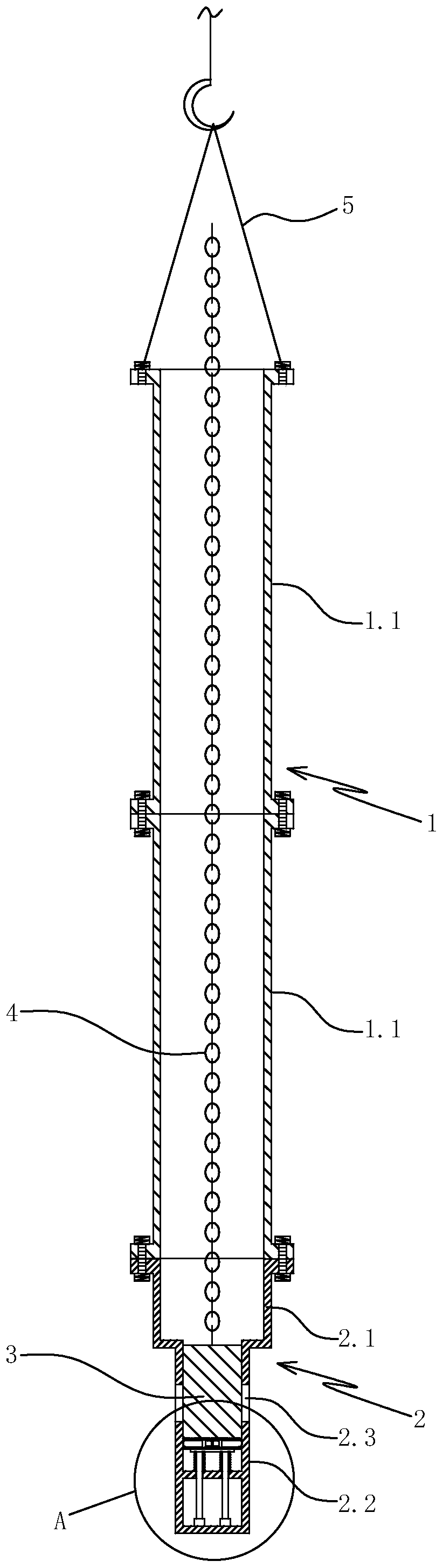

[0036] Specific embodiment one: as figure 1 , figure 2 As shown, a deep cement soil slurry sampling device includes a lowering connecting pipe 1 , a bottom sampling pipe 2 , a sliding block 3 and a connecting rope 4 .

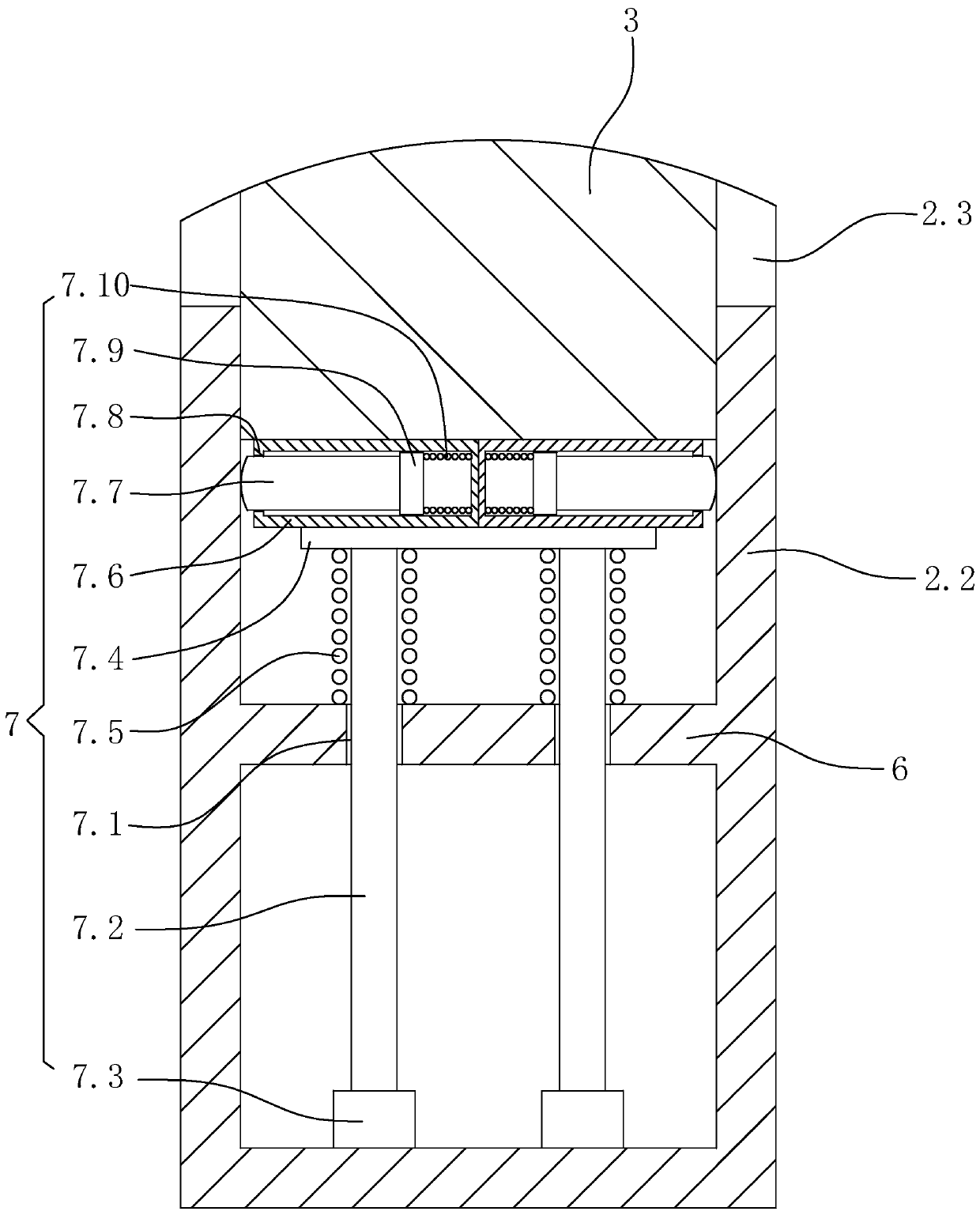

[0037]The upper end of the bottom sampling pipe 2 is connected with the lower end of the lowering connecting pipe 1, and the upper end of the bottom sampling pipe is connected with the lower end of the lowering connecting pipe. The lower end of the bottom sampling tube is closed. The bottom sampling pipe includes a lower slurry feed pipe 2.2 and an upper slurry feed pipe 2.1 located above the lower slurry feed. A stepped surface is formed between the upper slurry feeding pipe and the lower slurry feeding pipe, and the cross-sectional area of the upper slurry feeding pipe is greater than that of the lower slurry feeding pipe. A slurry inlet 2.3 is provided on the side wall of the slurry lower feeding pipe. The sliding block 3 is slidably arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com