A method and device for simulating lightning strike damage of composite materials

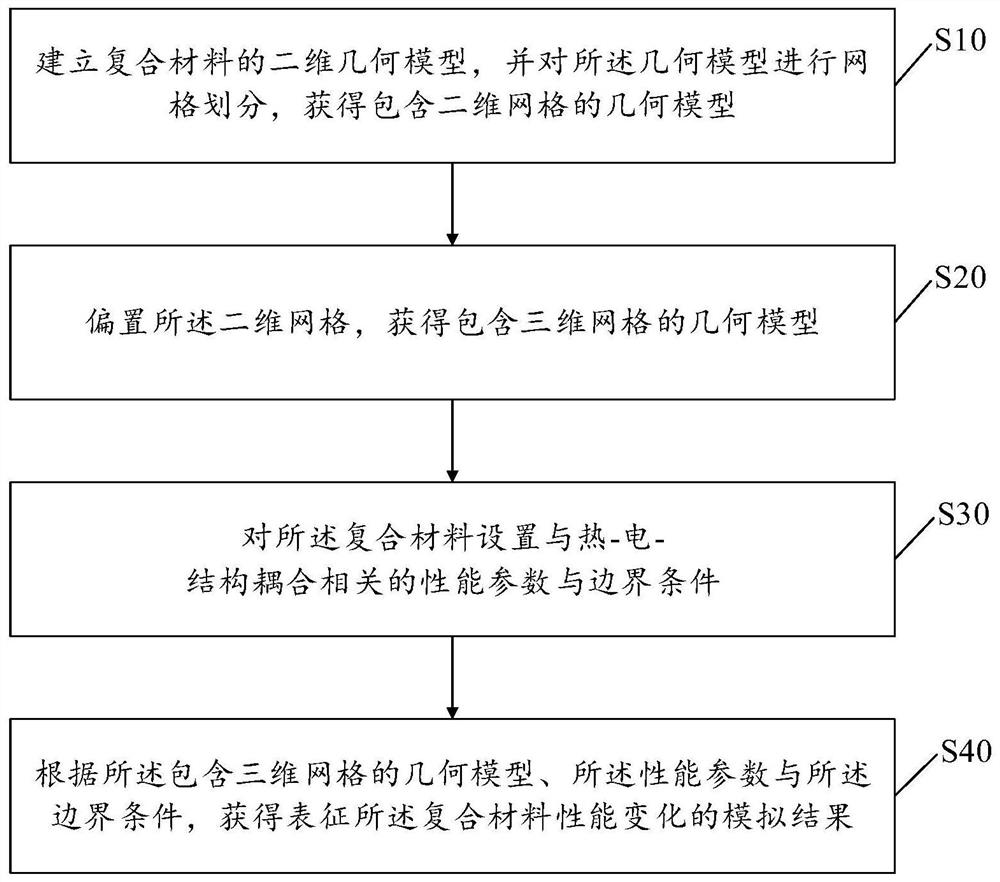

A composite material and damage simulation technology, applied in computer material science, 3D modeling, instruments, etc., can solve the problem of lack of lightning strike simulation, and achieve the effect of avoiding lightning strike test and reducing cost and test cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

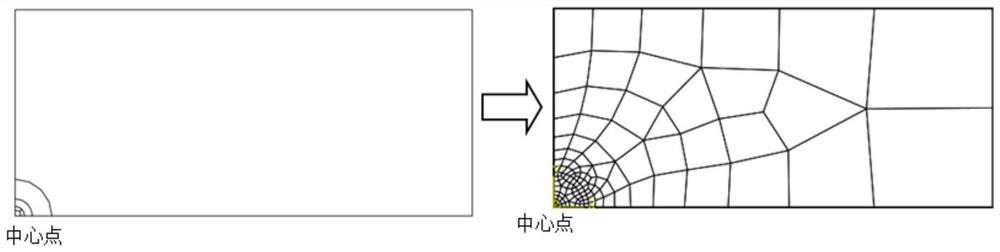

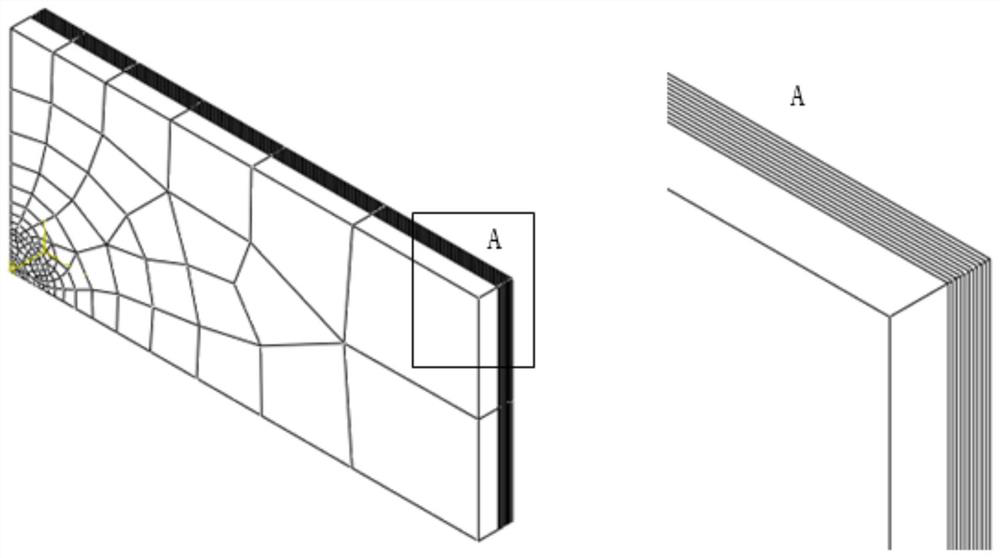

Method used

Image

Examples

Embodiment approach

[0095] As an optional implementation manner, the boundary conditions include any one or more of the following:

[0096] Concentrated current, electric potential, displacement control, initial temperature, heat exchange coefficient and radiation coefficient of the composite material.

[0097] As an optional implementation, the method is applied in the software ABAQUS.

[0098] As an optional implementation manner, the calculation module 604 is specifically configured to:

[0099] According to the performance parameters, design a user subroutine for calculating the degree of pyrolysis, wherein the degree of pyrolysis represents the degree of performance attenuation of the composite material; according to the geometric model containing the three-dimensional grid, the performance parameters and A simulation model is obtained for the boundary conditions; a simulation calculation is performed according to the simulation model and the user subroutine to obtain the simulation result....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com