HSD connector

A connector and male head technology, applied in the field of waterproof and dustproof HSD connectors, can solve the problems that cannot meet the requirements of IPXX waterproof & dustproof, achieve the effect of optimizing the connector structure and solving the effect of waterproof and dustproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An HSD connector, comprising a male connector 1 and a female connector 2 that can be mated with each other;

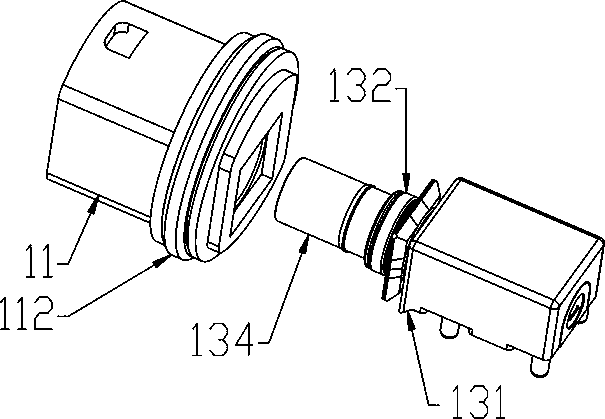

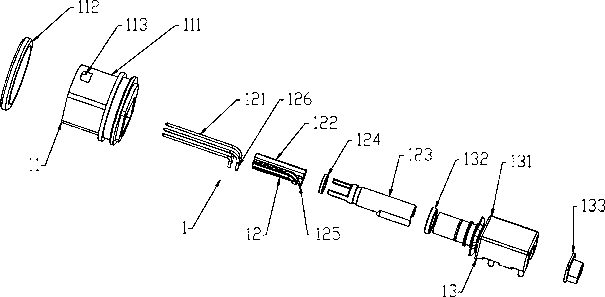

[0051] as attached figure 1 and 3 As shown, the male connector 1 includes a male body assembly 11, a male terminal assembly 12 and a die casting assembly 13;

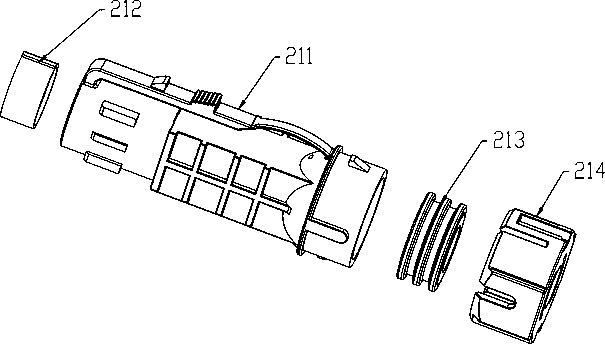

[0052] as attached figure 2 and 4 As shown, the female connector 2 includes a female body assembly 21, a female terminal assembly 22 and a shield assembly 23;

[0053] The male terminal assembly 12 is inserted into the die casting assembly 13; one end of the combination of the male terminal assembly 12 and the die casting assembly 13 is crimped into the male main body assembly 11;

[0054] The female terminal assembly 22 and the shielding assembly 23 are inserted into the female main body assembly 21;

[0055] The male body assembly 11 includes a male body part 111 and an outer sealing ring 112;

[0056] The male terminal assembly 12 includes a male terminal 121, a male terminal guard and a male te...

Embodiment 2

[0065] On the basis of embodiment one, as attached image 3 As shown, the die casting body 131 includes a mating body 134 ; the mating body 134 is press-fitted into the male main body 111 ;

Embodiment 3

[0067] On the basis of the above-mentioned embodiments, if the attached image 3 As shown, the male terminal guard includes a male terminal guard 1 122 and a male terminal guard 2 123; the male terminal guard 1 122 is set on the outer circumference of the male terminal 121; the male terminal guard 2 123 is set on the male The first 122 outer circumference of the head terminal protection piece; the male terminal sealing ring 124 is set on the junction of the second male terminal protection piece 123 and the end of the male main body 111 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com