Process method for making plaid matching shirt lapel through template

A process method and a technology for lower collar pieces, which are applied in the field of garment manufacturing, can solve the problems of inadequate process, quality decline, increase in production process, etc., and achieve the effect of overcoming lattice dislocation and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is a kind of processing method that uses template to do the collar piece of check shirt, and it comprises the following steps:

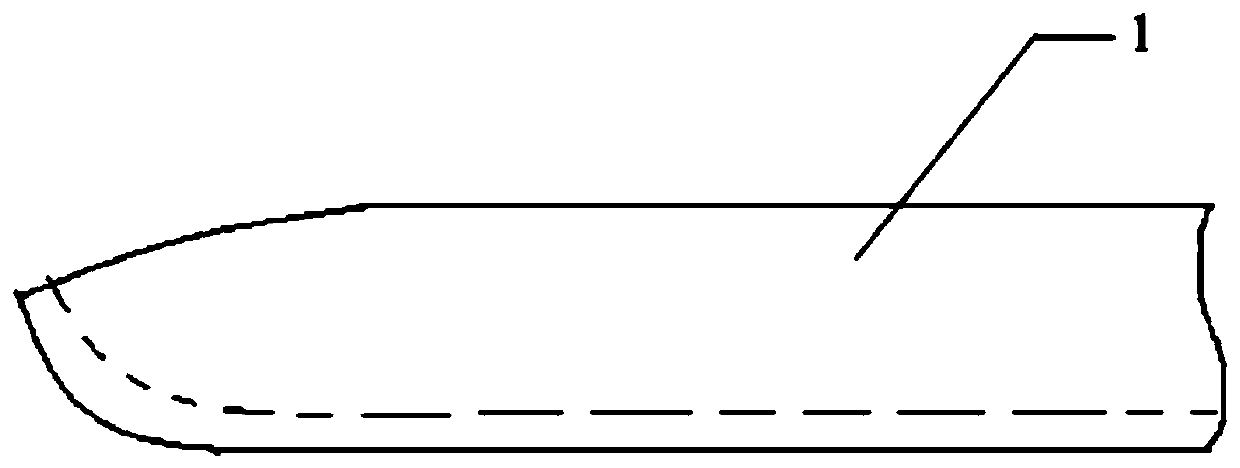

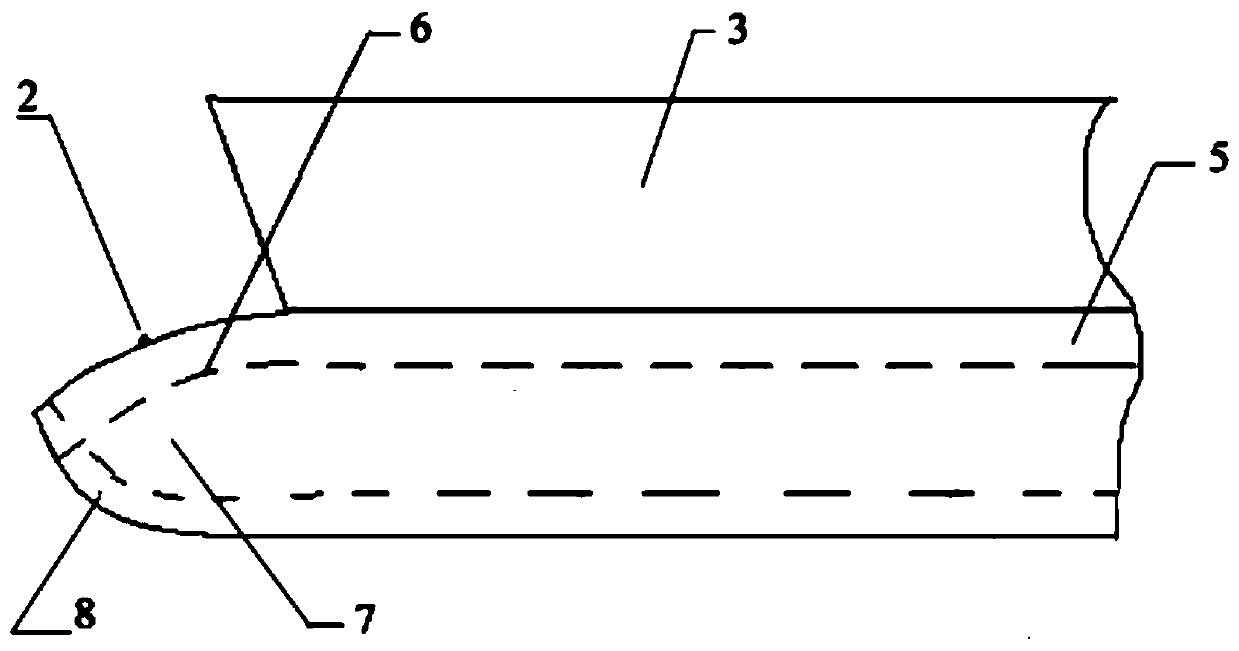

[0030] Step 1): Use a template to align the stripes at the left and right ends of the lower collar piece 1, and use at least two template points 2 to buckle and shape the lower edge of the lower collar piece 1. The lower collar piece 1 includes the lower collar surface 4 and the lower collar inner 5;

[0031] Step 2): Cut the lower collar piece 1 with a sewing machine with a knife car, cut and trim the lower edge seam of the lower collar piece 1, and leave a 0.4cm wide seam allowance;

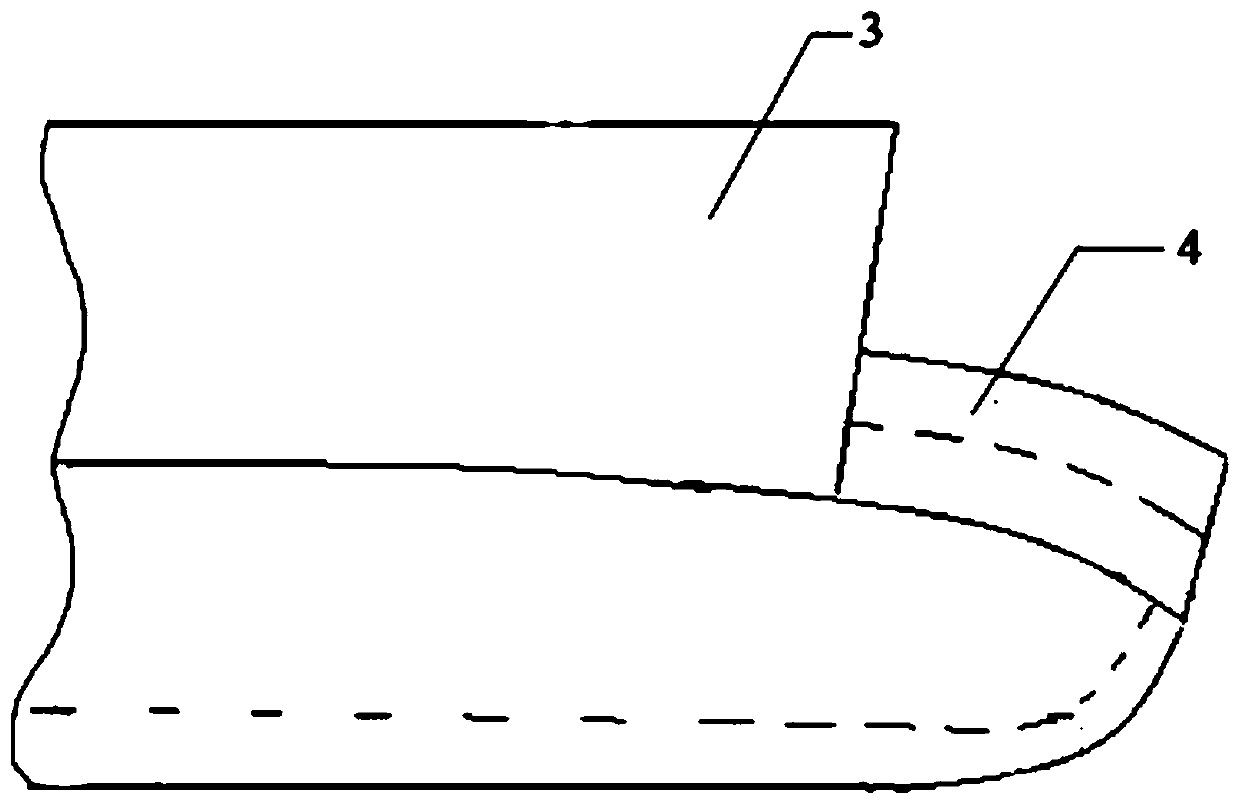

[0032] Step 3) Align the point 2 on the lower collar 4 with the slot of the template, align the ironing side with the edge of the template, then place the upper collar 3 on the lower collar 4 according to the shape of the template, and then place the inner 5 of the lower collar Put it on the upper collar piece 3, use a 0.5mm pen core to vertical...

Embodiment 2

[0038] This embodiment is a kind of processing method that uses template to do the collar piece of check shirt, and it comprises the following steps:

[0039] Step 1): Use a template to align the stripes at the left and right ends of the lower collar piece 1, and use at least two template points 2 to buckle and shape the lower edge of the lower collar piece 1. The lower collar piece 1 includes the lower collar surface 4 and the lower collar inner 5;

[0040] Step 2): Cut the lower collar piece 1 with a sewing machine with a knife car, cut and trim the lower edge seam of the lower collar piece 1, and leave a 0.6cm wide seam allowance;

[0041] Step 3) Align the point 2 on the lower collar 4 with the slot of the template, align the ironing side with the edge of the template, then place the upper collar 3 on the lower collar 4 according to the shape of the template, and then place the inner 5 of the lower collar Put it on the upper collar piece 3, use a 0.5mm pen core to vertical...

Embodiment 3

[0047] This embodiment is a kind of processing method that uses template to do the collar piece of check shirt, and it comprises the following steps:

[0048] Step 1): Use a template to align the stripes at the left and right ends of the lower collar piece 1, and use at least two template points 2 to buckle and shape the lower edge of the lower collar piece 1. The lower collar piece 1 includes the lower collar surface 4 and the lower collar inner 5;

[0049] Step 2): Cut the lower collar piece 1 with a sewing machine with a knife car, cut and trim the lower edge seam of the lower collar piece 1, and leave a 0.8cm wide seam allowance;

[0050] Step 3) Align the point 2 on the lower collar 4 with the slot of the template, align the ironing side with the edge of the template, then place the upper collar 3 on the lower collar 4 according to the shape of the template, and then place the inner 5 of the lower collar Put it on the upper collar piece 3, use a 0.5mm pen core to vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com