Adjustable rotation auxiliary roller device for cold bend forming machine

A cold bending forming machine and auxiliary roller technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as not being well applicable, and achieve the effects of small springback, easy adjustment and good stress condition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

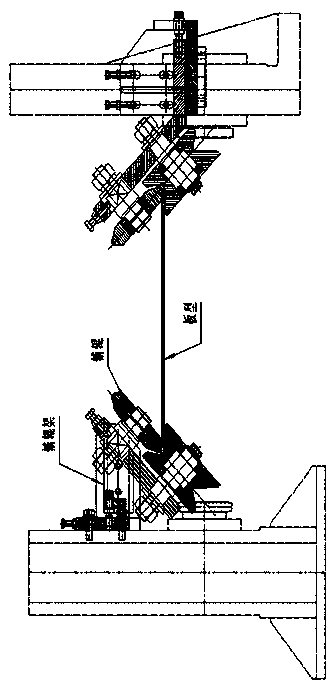

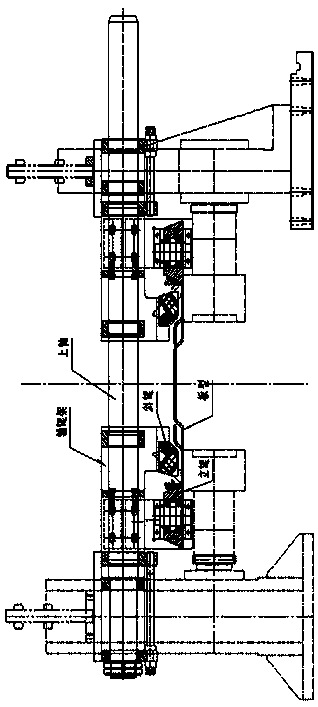

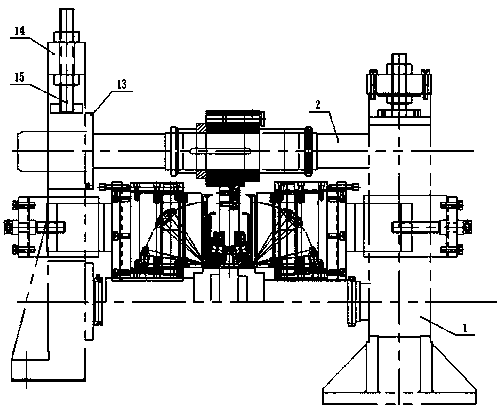

[0023] The technical solution of the present invention is described in detail in conjunction with the accompanying drawings. An adjustable rotating auxiliary roller device for cold roll forming machines includes opposite arches 1 and upper shafts 2 arranged between the opposite arches 1. On the upper shaft 2 An axial keyway is provided, and the fixed sleeve 3 is fixed on the upper shaft 2 through the flat key 4 matched with the keyway. The other side of the rotating seat 5 is flush with the axial end of the fixed sleeve 3 and is positioned by the compression sleeve 6. The fixed sleeve 3 is positioned and locked by the positioning pin 7 axially penetrating through the backstop step and the pin hole of the rotating seat 5. There are multiple sets of asymmetric auxiliary roller arms 8 fixed by screws on the outer side of the seat 5 along the circumferential direction. The upper shaft 2 is respectively sleeved with bushings 11 for adjusting the left and right positions of the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com