Automatic holding type gas-liquid chuck

A gas-hydraulic, automatic technology, applied in the direction of the chuck, etc., can solve the problem of unbalanced clamped workpieces, and achieve the effects of high precision fit, improved integrity, and precise travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

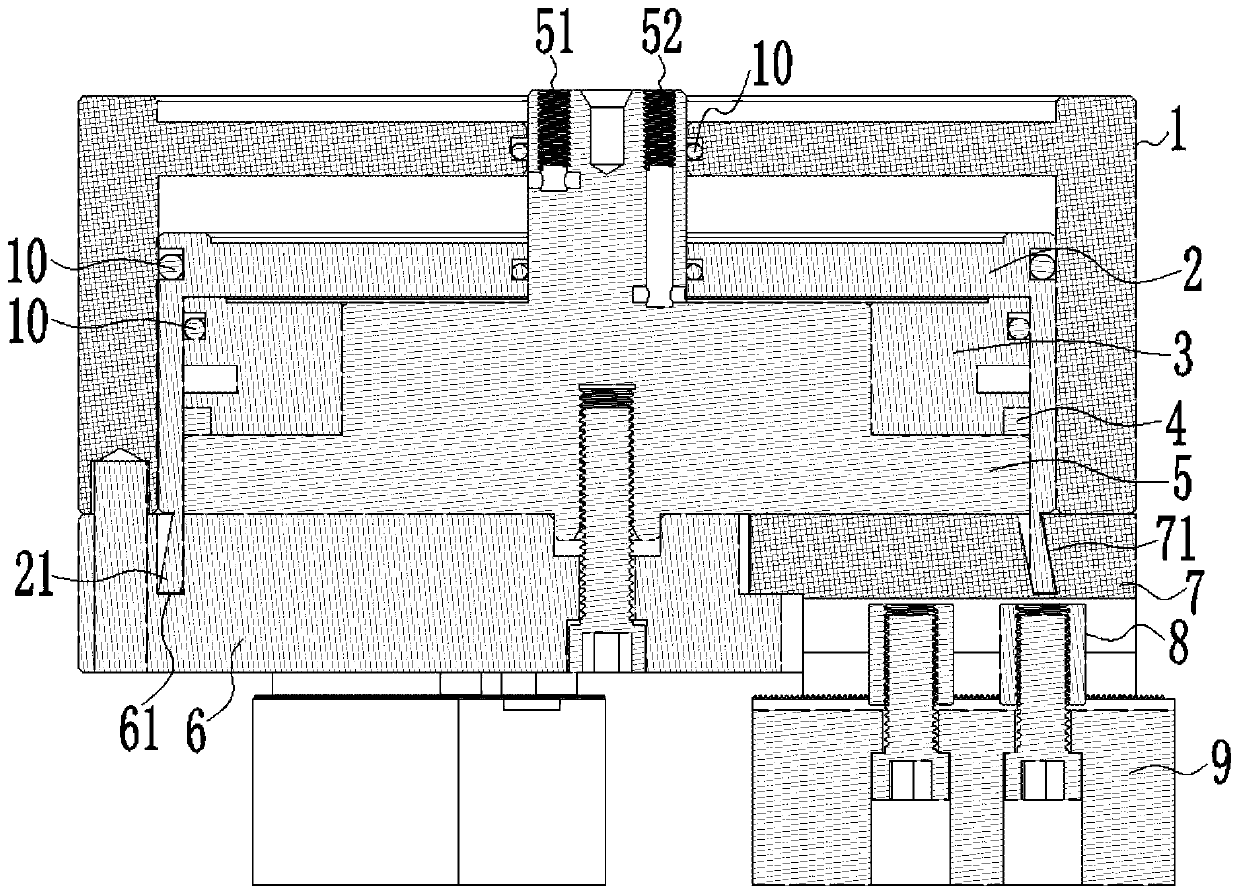

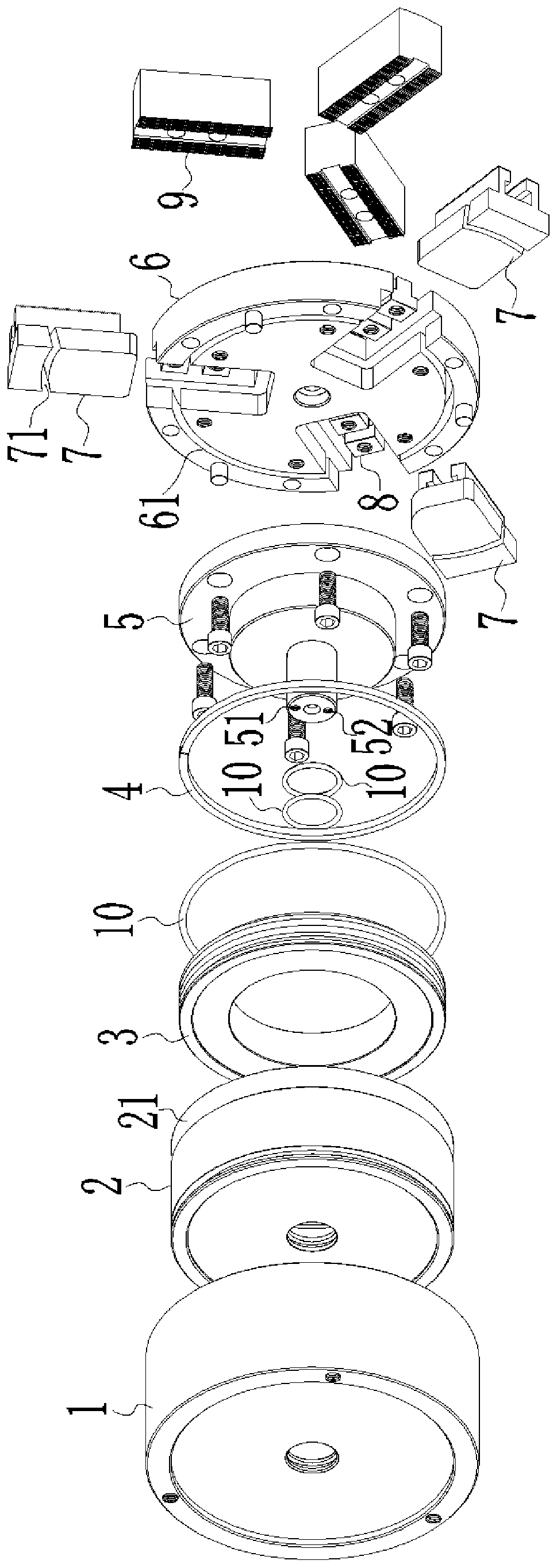

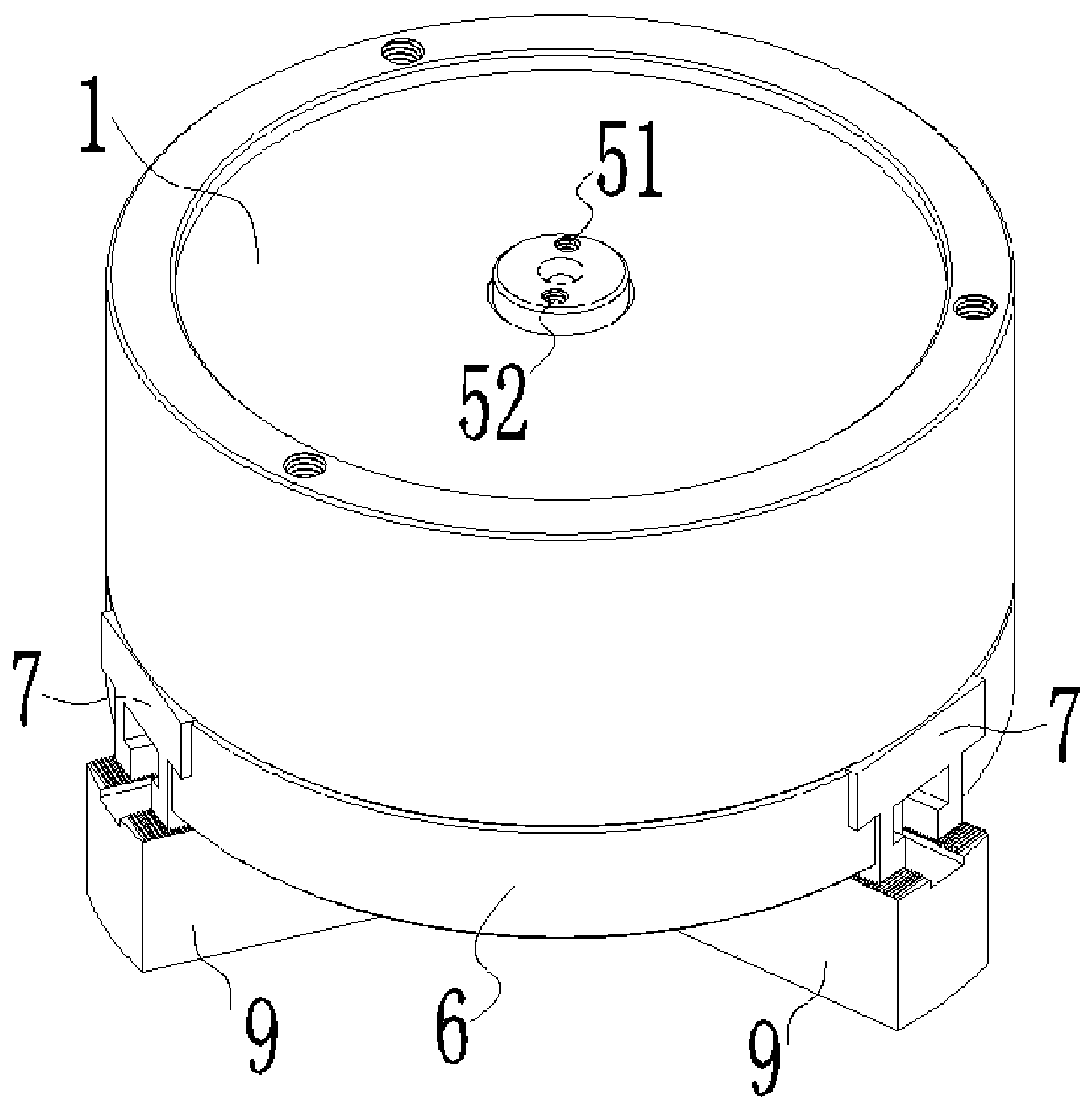

[0031] A self-clamping gas-liquid chuck, such as Figure 1 to Figure 4 As shown, it includes a housing 1 , a piston cylinder 2 , a core seat 5 , a base 6 , a slider 7 and a claw 9 . Wherein, the piston cylinder 2 is sleeved in the housing 1 and can slide freely in the housing 1 , and the centers of the housing 1 and the piston cylinder 2 are both provided with a central hole. In the center of the core base 5, there is a central column that runs through the center hole of the housing 1 and the piston cylinder 2. The a medium hole 51 and the b medium hole 52 are arranged on the central column. The a medium hole 51 communicates between the housing 1 and the piston cylinder 2. , B medium hole 52 communicates between the piston cylinder 2 and the core seat 5 . The bottom of the base 6 is connected with claws 9 for clamping workpieces.

[0032] Such as Figure 1 to Figure 4 As shown, the bottom of the piston cylinder 2 has a complete circular wedge-shaped mouth 21, and the openin...

Embodiment 2

[0036] Most of the technical solutions of this embodiment are the same as those of the above-mentioned embodiments, but the following configuration structures are adopted in particular:

[0037] Such as Figure 5 As shown, the bottom of the piston cylinder 2 has a complete circular wedge-shaped mouth 21, and the opening direction of the wedge-shaped mouth 21 is toward the inner side of the piston cylinder 2, forming a reverse trumpet-shaped structure. When the piston cylinder 2 is pushed upward, the wedge-shaped mouth 21 gradually extends out of the base 6, and the claw 9 clamps the workpiece to make the wedge-shaped mouth 21 move inwardly. The outer sidewall of the limiting groove 61 is tightened by the outward displacement.

[0038] The bottom of the piston cylinder 2 of the present invention is a complete circular wedge-shaped opening 21. When the three sets of claws 9 clamp the workpiece under force, the three sets of claws 9 drive the slider 7 so that the wedge-shaped op...

Embodiment 3

[0040] As preferably, in order to realize the present invention better, optimize further on the basis of above-mentioned embodiment, especially adopt following setting structure:

[0041] like Figure 1 to Figure 4 As shown, the core seat 5 has a stepped structure, and the core seat 5 and the piston cylinder 2 form a cavity at the step position, and the elastic member 3 is arranged in the cavity. The material of the elastic member 3 can be nylon, rubber, silica gel, beef tendon or hollow metal and other materials with elastic expansion and contraction.

[0042] When the medium (gas or liquid) enters between the casing 1 and the piston cylinder 2 from the a medium hole 51, or enters between the piston cylinder 2 and the core seat 5 from the b medium hole 52, the piston cylinder 2 moves in the casing 1 to The driving claw 9 clamps the workpiece. In this process, due to the existence of the elastic member 3, the outer wall of the piston cylinder 2 is tightly attached to the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com