File cover adhesive-injection and adhesion machine

A file bag, gluing machine technology, applied in the device, printing, office supplies and other directions of sealing and sealing bags, can solve the problem of low efficiency of manual sealing of file bags, and achieve the effect of solving low efficiency and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

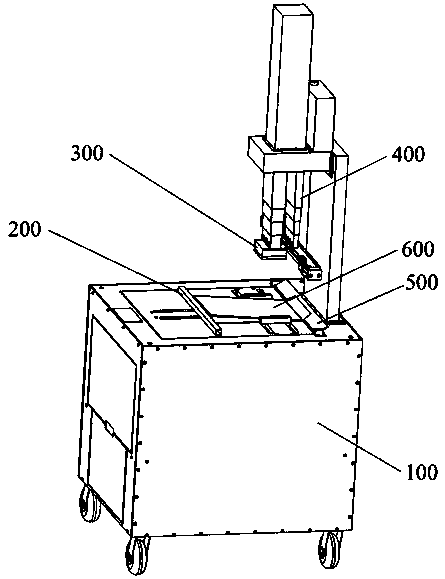

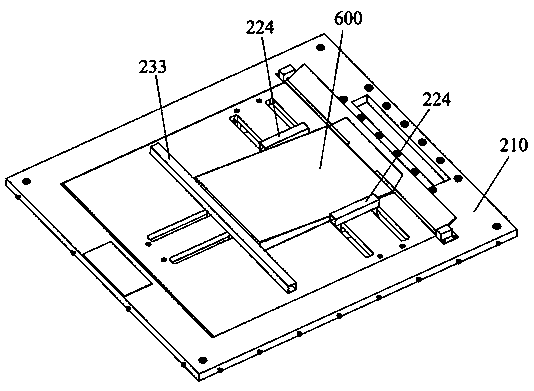

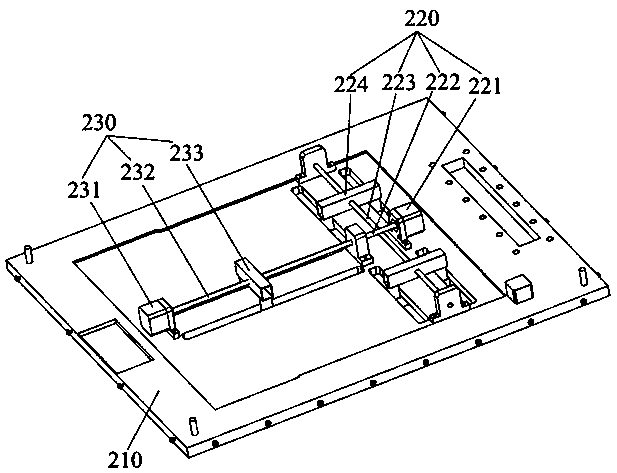

[0032] Such as figure 1 As shown, the present embodiment provides a portfolio glue injection bonding machine, comprising: a frame 100, a positioning device 200, a pressing device 300, a glue injection device 400 and a sealing device 500; wherein, the positioning device 200 is arranged on On the frame 100, the pressing device 300 is arranged above the positioning device 200, the glue injection device 400 is arranged on one side of the pressing device 300, and the sealing device 500 is arranged on the One side of the positioning device 200.

[0033] The positioning device 200 is used for lateral positioning and longitudinal positioning of the file bag 600; the pressing device 300 is used for pressing the file bag 600 after the positioning device 200 is positioned to prevent the file bag from 600 is offset during the sealing process; the glue injection device 400 is used to inject glue on the seal of the file bag 600 after the press-down device 300 is pressed; the sealing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com