Hinged structure

A hinged, anti-off structure technology, applied in the mechanical field, can solve the problems of increased production process and the influence of hinged parts, and achieve the effects of convenient processing, quick disassembly and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

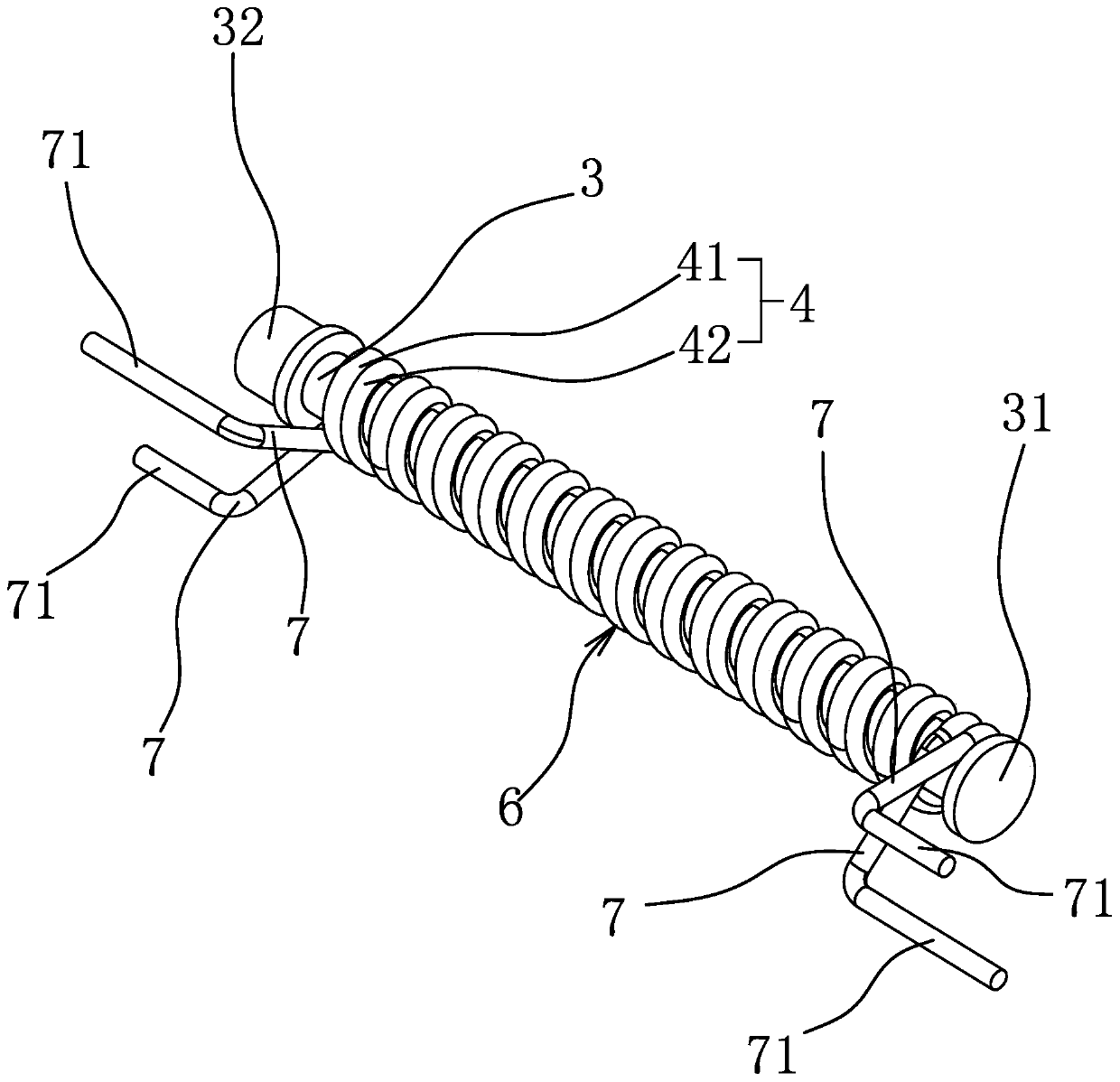

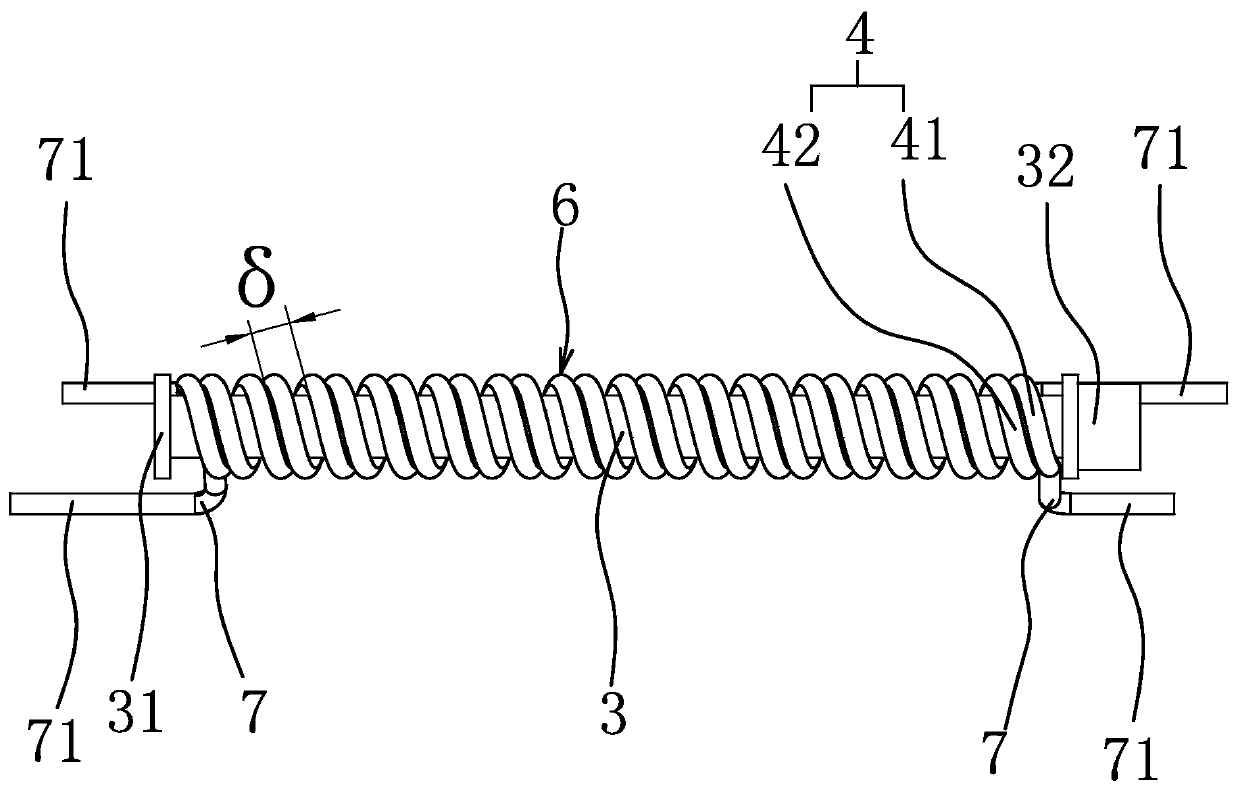

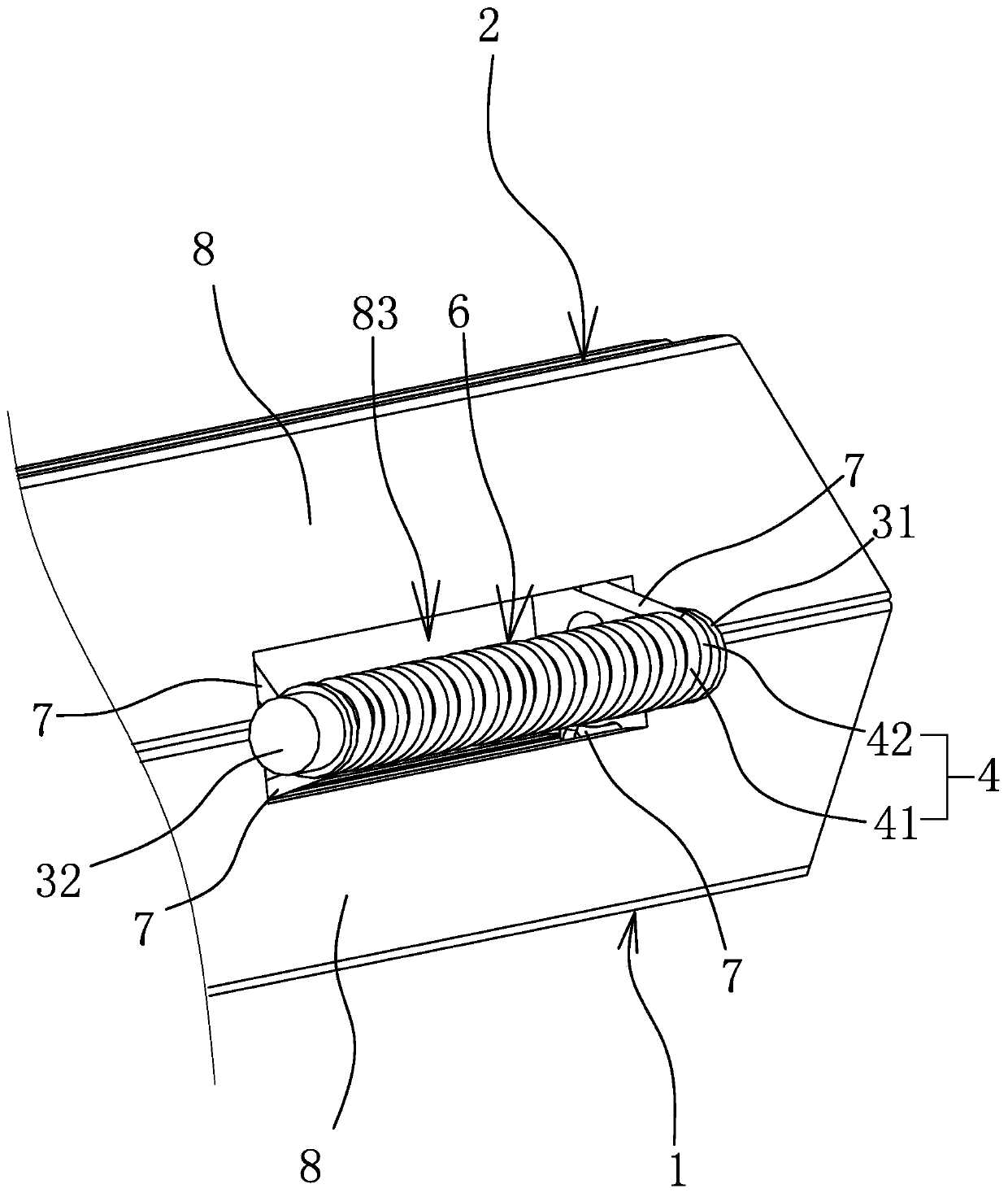

[0043] This hinge structure is used to hinge part one 1 and part two 2, such as figure 1 and figure 2 As shown, the hinged structure comprises pin shaft 3, and pin shaft 3 is sheathed with two torsion springs 4, and two torsion springs 4 are respectively torsion spring one 41 and torsion spring two 42, and torsion spring one 41 and torsion spring two 42 can Perform relative rotation. Torsion spring one 41 and torsion spring two 42 are all formed by wire winding, and torsion spring one 41 and torsion spring two 42 all include the helical part 6 that is rotatably sleeved on the bearing pin 3 and two helical parts that are respectively formed by the helical part 6. The insertion arm 7 extended from the end, the insertion arm 7 is L-shaped, one end of the insertion arm 7 is connected to the spiral part 6, and the other end of the insertion arm 7 is bent in a direction away from the spiral part 6 to form an insertion section 71 , and the length direction of the inserting section...

Embodiment 2

[0054] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 11 As shown, part one 1 is provided with two insertion holes 1a, part two 2 is provided with two insertion holes 2a, and the insertion sections 71 of torsion spring one 41 and two insertion arms 7 are respectively inserted in In the two insertion holes 1a, the insertion sections 71 of the two insertion arms 7 of the torsion spring 2 42 are respectively inserted in the two insertion holes 2a. When carrying out the processing of part one 1 and part two 2, only need to process out inserting hole one 1a or inserting hole two 2a on part one 1 and part two 2, it is comparatively convenient to manufacture. In the actual manufacturing process, the aperture of the first insertion hole 1a can be greater than or equal to the diameter of the corresponding insertion section 71, and the aperture of the second insertion hole 2a can also be greater than or equa...

Embodiment 3

[0056] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the first torsion spring 41 and the second torsion spring 42 are wound by metal wires of the same diameter, and the axial gap δ between the two is equal, and the torsion spring 2 The axial gap δ of spring one 41 spiral portion 6 is 1.5 times of the wire diameter of torsion spring two 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com