Alcohol injection device

A flow control device and tank technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of increasing pipeline pressure drop, large labor intensity, blocking and stopping transportation, etc., and reduce manufacturing and use. Cost, reduce labor intensity, and avoid the effect of methanol spillage to harm the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

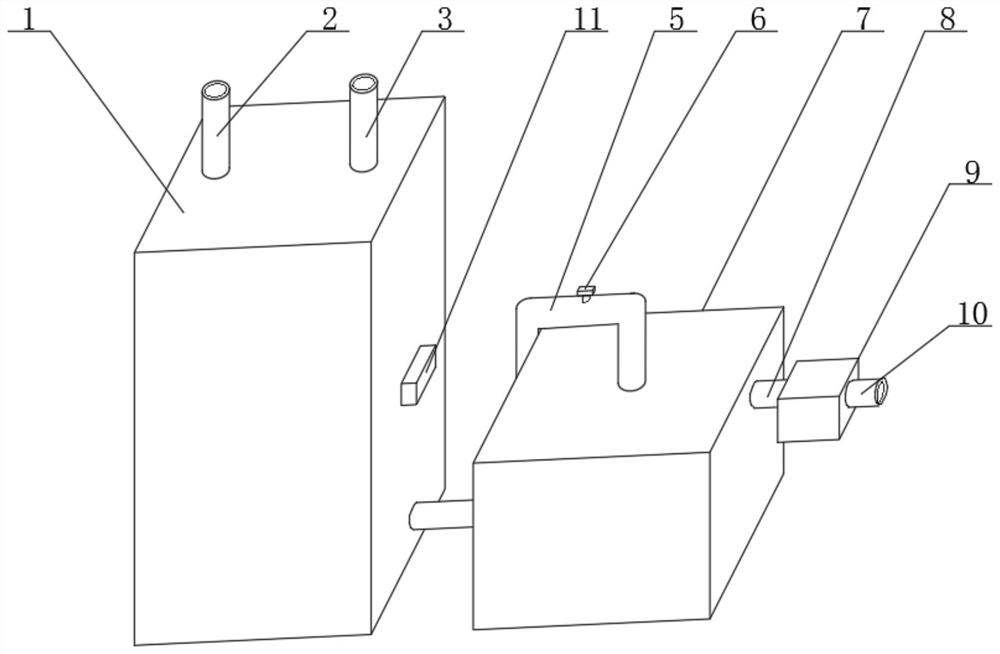

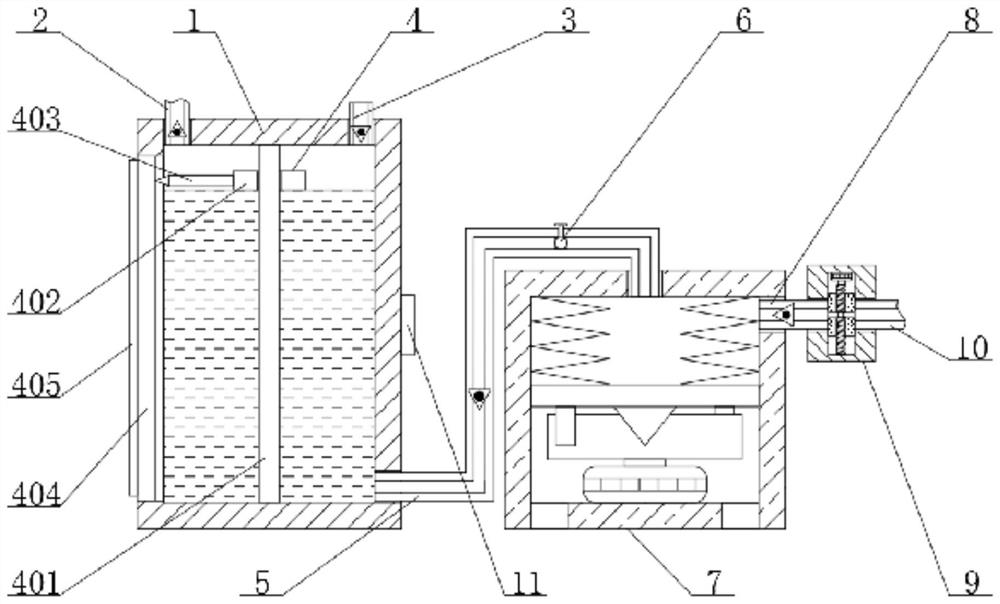

[0028] see figure 1 , figure 2 , Figure 4 , Figure 6 and Figure 7 , the present invention provides a technical solution:

[0029]The alcohol injection device comprises a tank body 1, the top surface of the tank body 1 is connected with an air inlet pipe 2 and an air outlet pipe 3 arranged left and right, and a liquid level observation device 4 is provided inside the tank body 1, and the liquid level observation device 4 includes a fixed shaft 401, Floating plate 402, pointer 403, toughened glass plate 404 and scale 405, the inside of the tank body 1 is fixedly connected with a fixed shaft 401, the outside of the fixed shaft 401 is slidingly connected with a floating plate 402, the left end of the floating plate 402 is fixedly connected with a pointer 403, the pointer A tempered glass plate 404 is slidingly connected to the left end of 403, and the tempered glass plate 404 is fixedly connected to the tank body 1, and a scale 405 is fixedly connected to the left end of t...

Embodiment 2

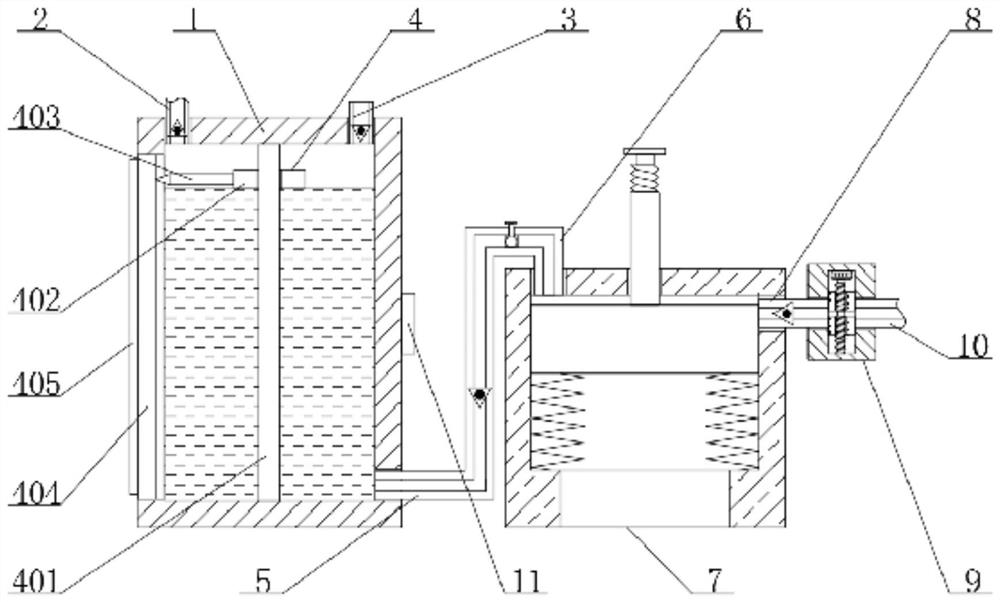

[0033] see image 3 , Figure 5 and Figure 7 , the present invention provides a technical solution:

[0034] The alcohol injection device comprises a tank body 1, the top surface of the tank body 1 is connected with an air inlet pipe 2 and an air outlet pipe 3 arranged left and right, and a liquid level observation device 4 is provided inside the tank body 1, and the liquid level observation device 4 includes a fixed shaft 401, Floating plate 402, pointer 403, toughened glass plate 404 and scale 405, the inside of the tank body 1 is fixedly connected with a fixed shaft 401, the outside of the fixed shaft 401 is slidingly connected with a floating plate 402, the left end of the floating plate 402 is fixedly connected with a pointer 403, the pointer A tempered glass plate 404 is slidingly connected to the left end of 403, and the tempered glass plate 404 is fixedly connected to the tank body 1, and a scale 405 is fixedly connected to the left end of the tempered glass plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com