A self-conducting disc-type series total heat exchange core

A full-heat exchange core and disc-type technology, applied in heating methods, household heating, household heating, etc., can solve problems such as uneven air volume distribution, uneven air volume distribution into the runner, air pollution, etc., to ensure humidity Exchange with temperature, high-efficiency humidity exchange, and solve the effect of space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

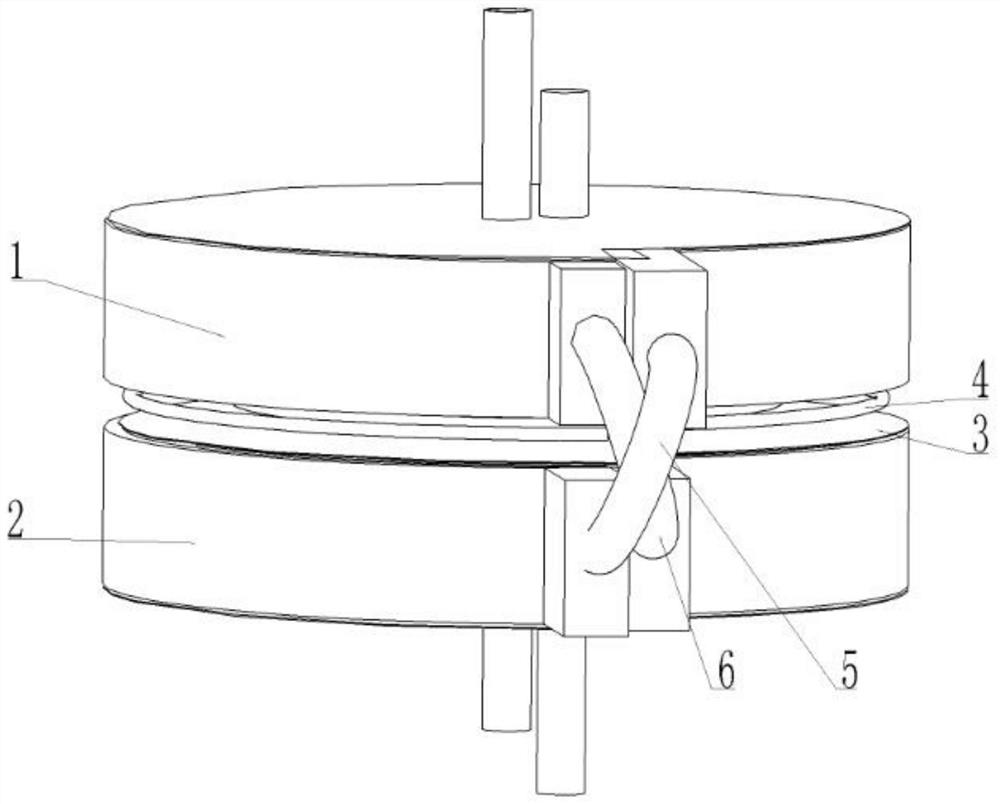

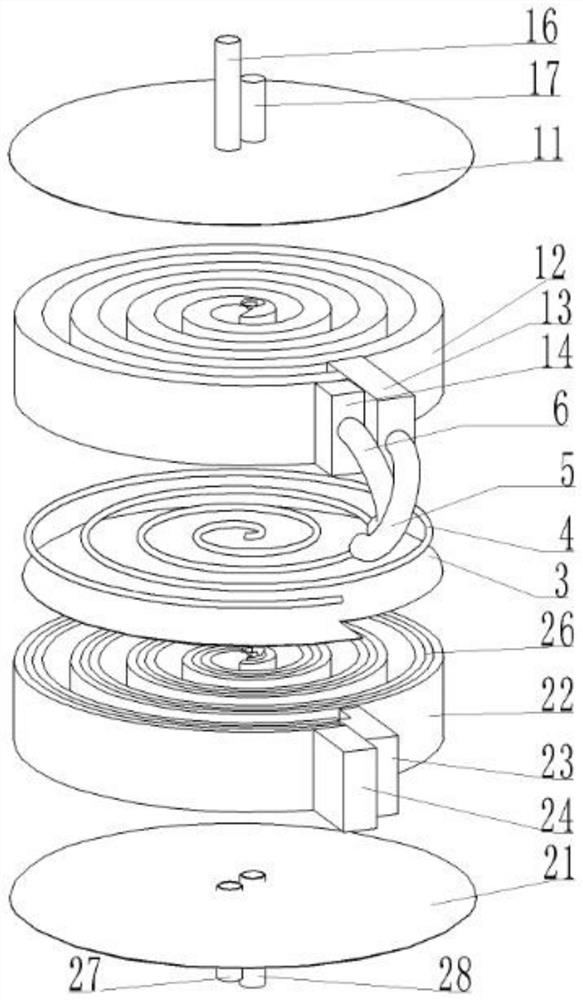

[0037] Such as figure 1 , figure 2 As shown, a self-conducting disc-type series total heat exchange core includes: an upper plate 1, a lower plate 2, a moisture-permeable film 3, a rubber bead 4, a first connecting pipe 5, and a second connecting pipe 6;

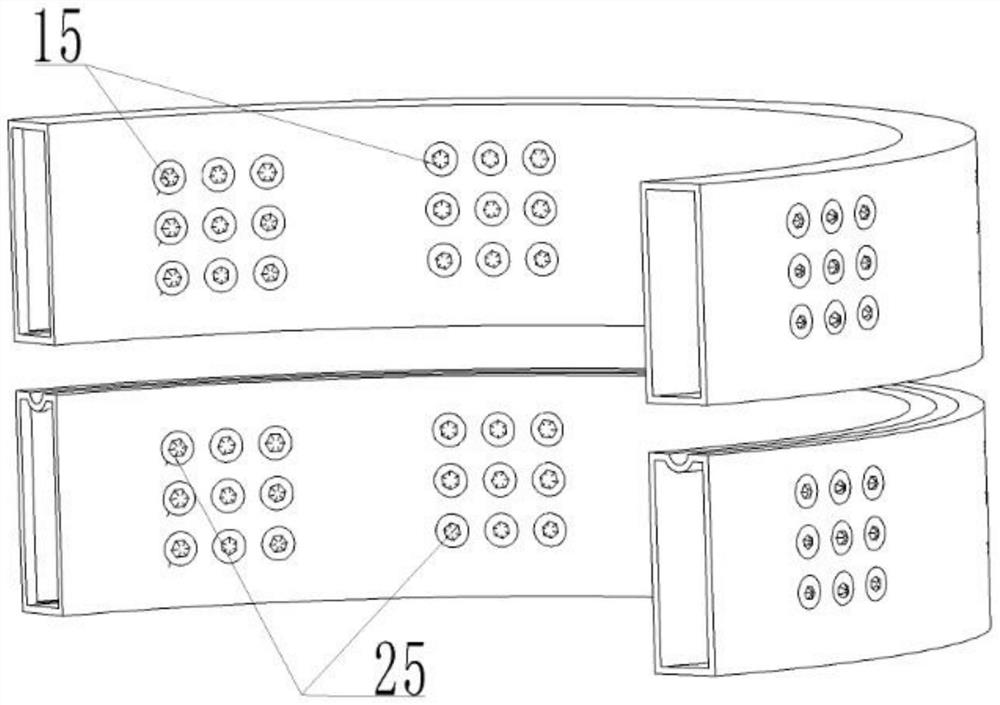

[0038] The upper plate 1 includes: an upper cover 11, an upper plate body 12, an upper gap lead-out portion 13, an upper hollow lead-out portion 14, an upper embossing 15, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com