Air plate type total heat recovery heat exchanger with turning wheel filtering devices

A filtration device and total heat recovery technology, applied in heat recovery systems, energy recovery systems for ventilation and heating, air treatment details, etc., which can solve problems such as mixed pollution, direct contact between fresh air and exhaust air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

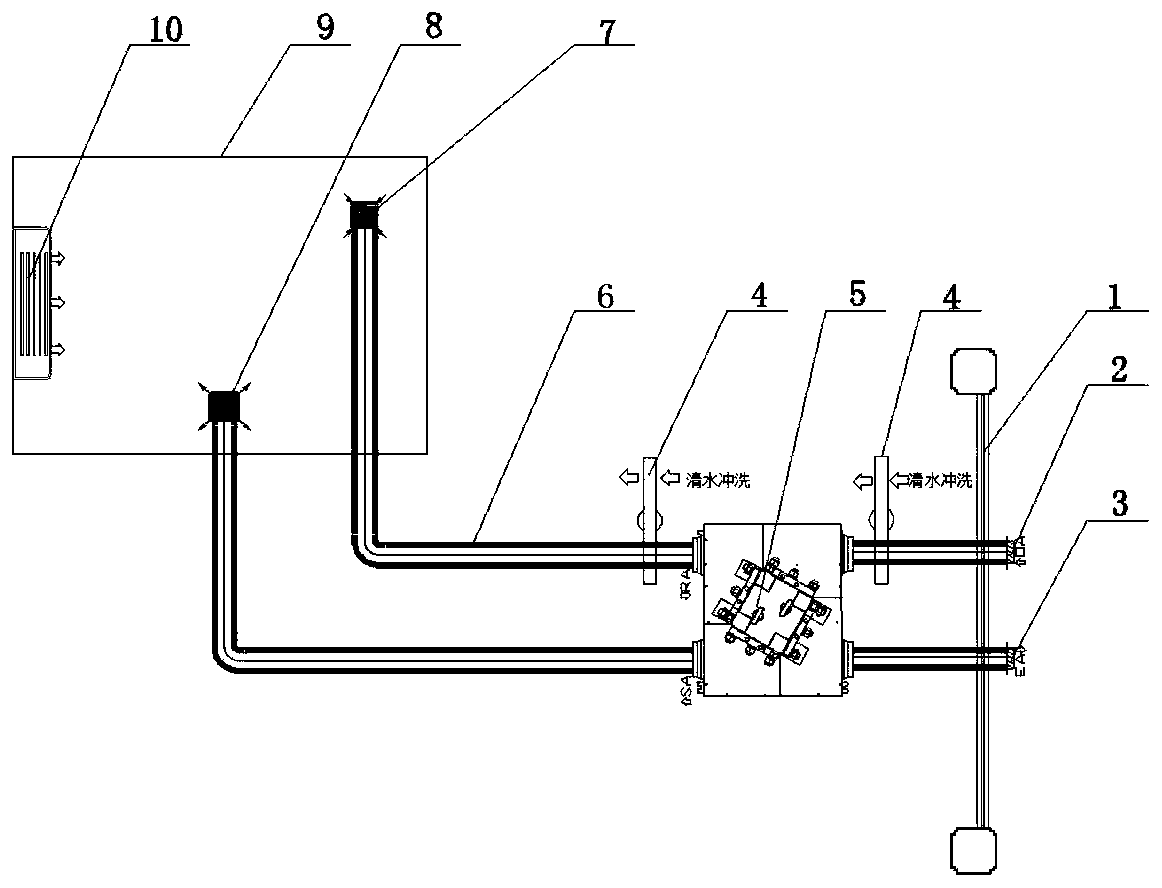

[0015] Such as figure 2 As shown, when the system works normally, the fresh air is introduced from the outside by the fresh air fan 2, and the dirty air is recovered from the room by the return air fan 7, and passes through the fiber filter in the working wheel filter device 4 on the respective pipelines respectively. After the material is filtered, it enters the air plate total heat recovery heat exchanger 5 for total heat exchange. The return air after the total heat exchange is discharged to the outside by the exhaust fan 3, and the fresh air after the total heat exchange is introduced into the room by the air supply fan 8.

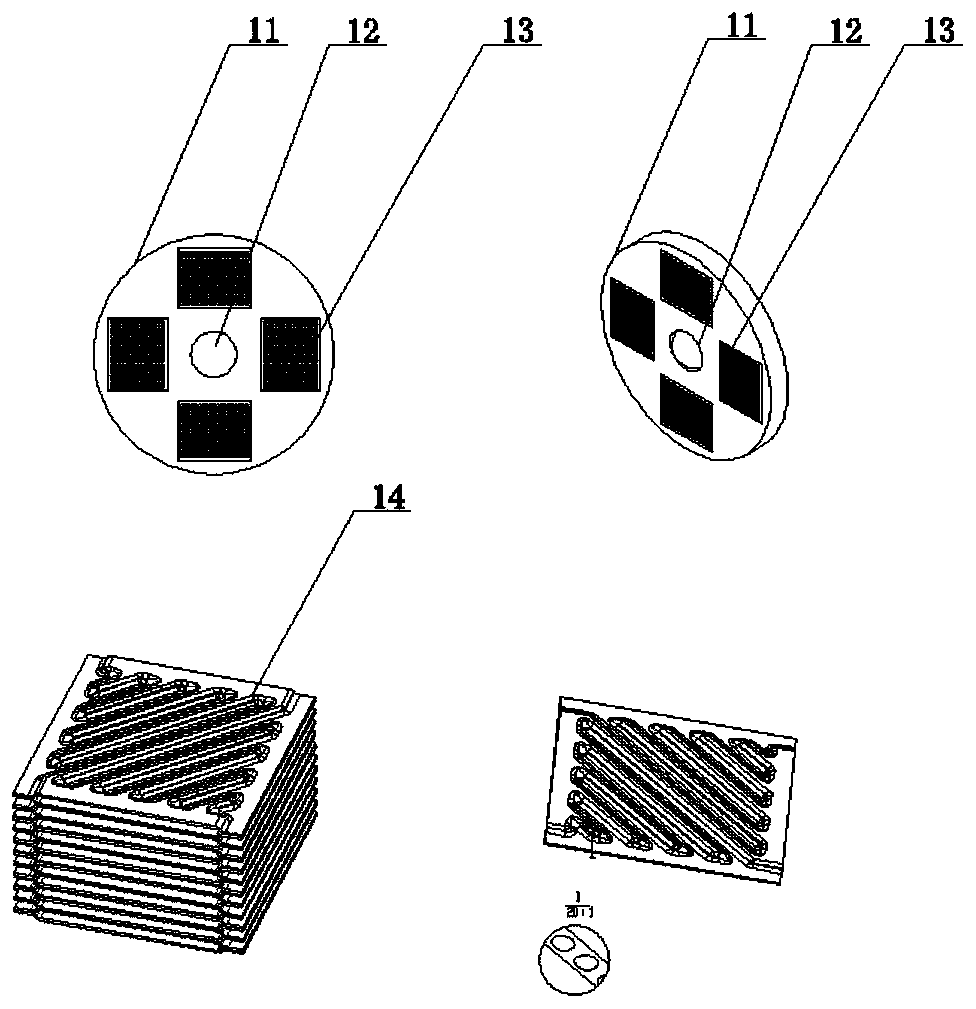

[0016] Such as figure 1 As shown, when the wheel filter device 4 is in the cleaning state, the wheel 11 rotates counterclockwise first, and then the filter material cleaning agent flows out from the spherical container 12 storing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com