Sorting device of brake pad steel backings

A technology for finishing devices and brake pads, applied in metal processing, etc., can solve problems such as low work efficiency, unfavorable fully automated production lines, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

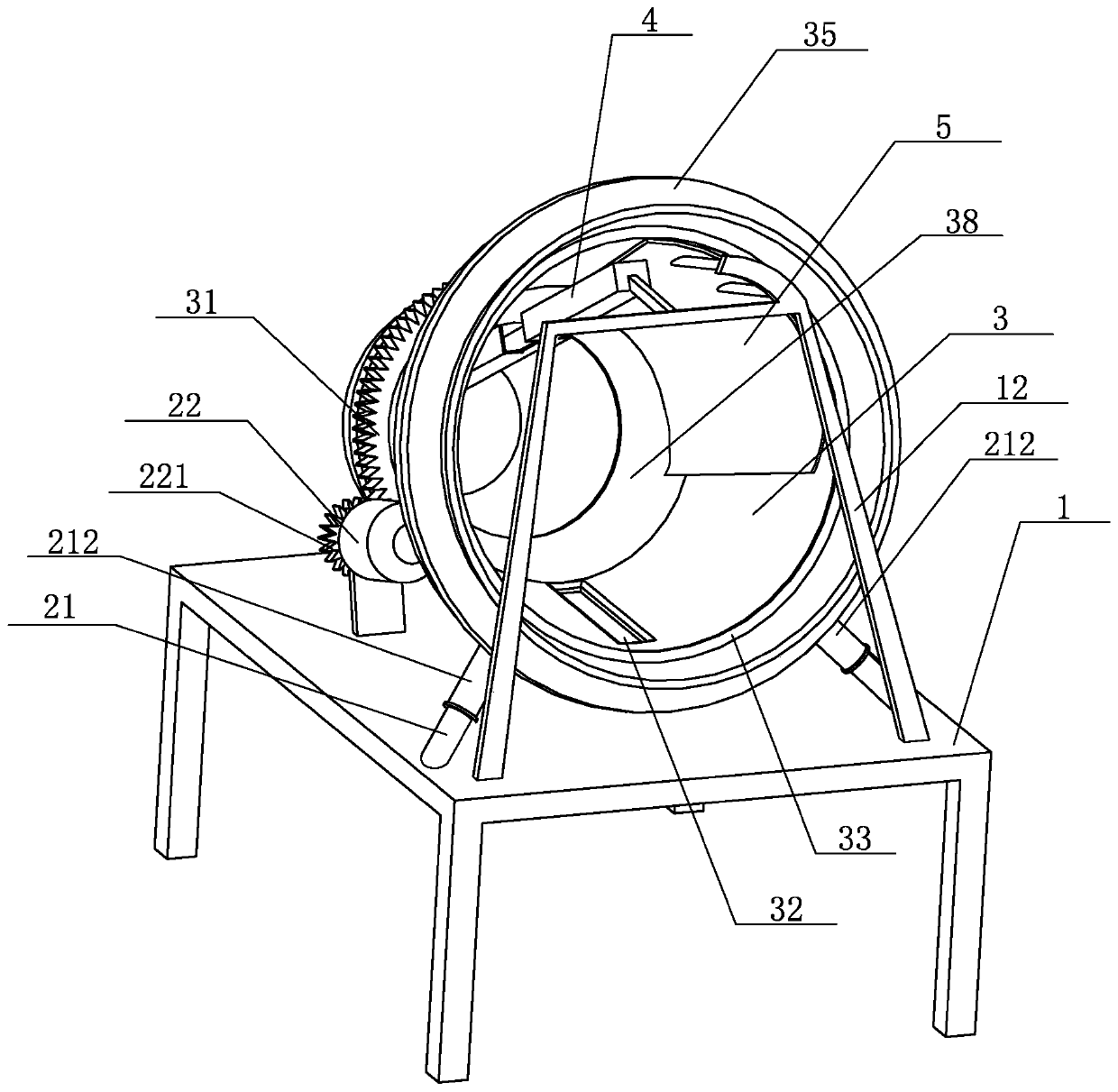

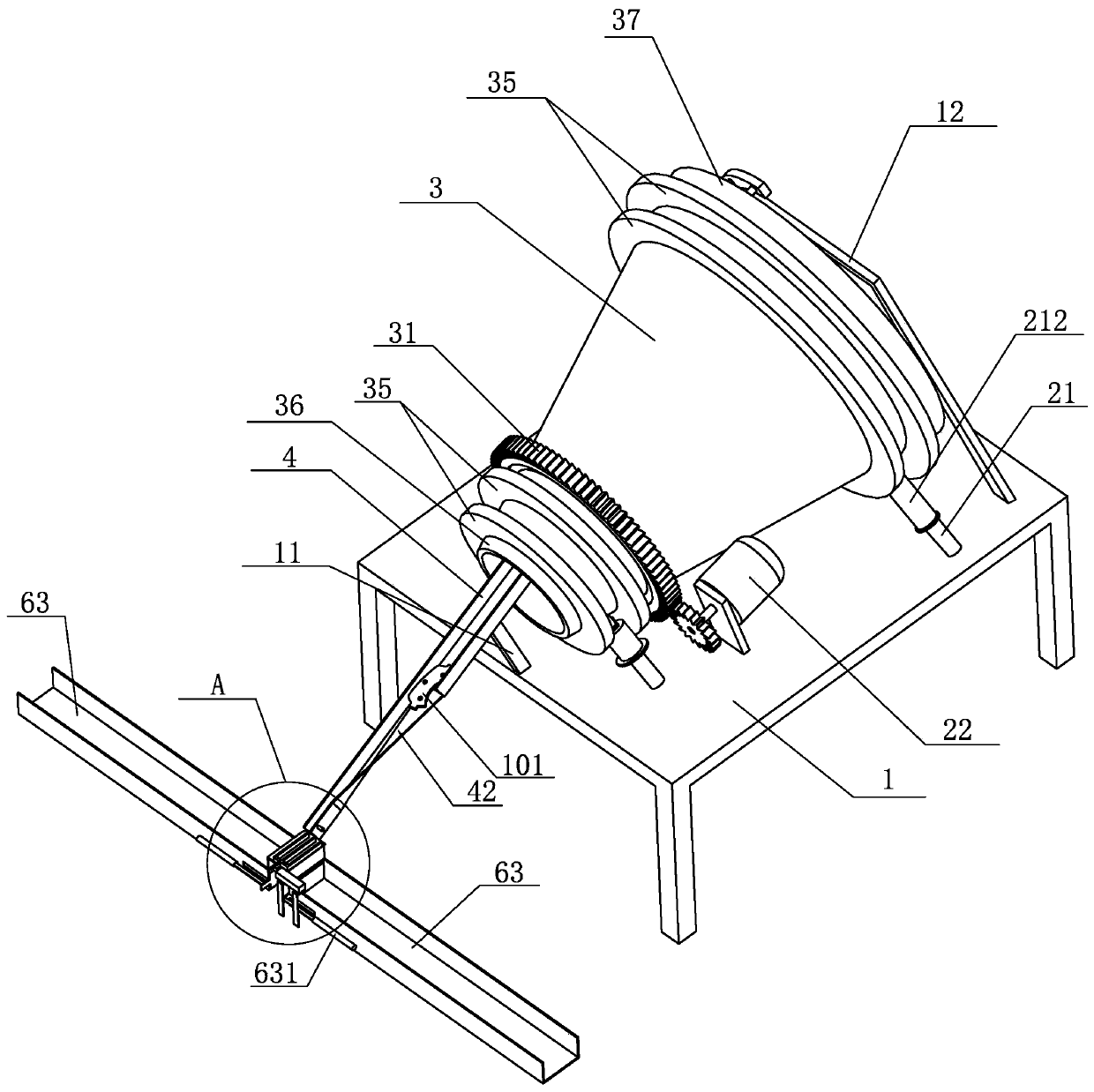

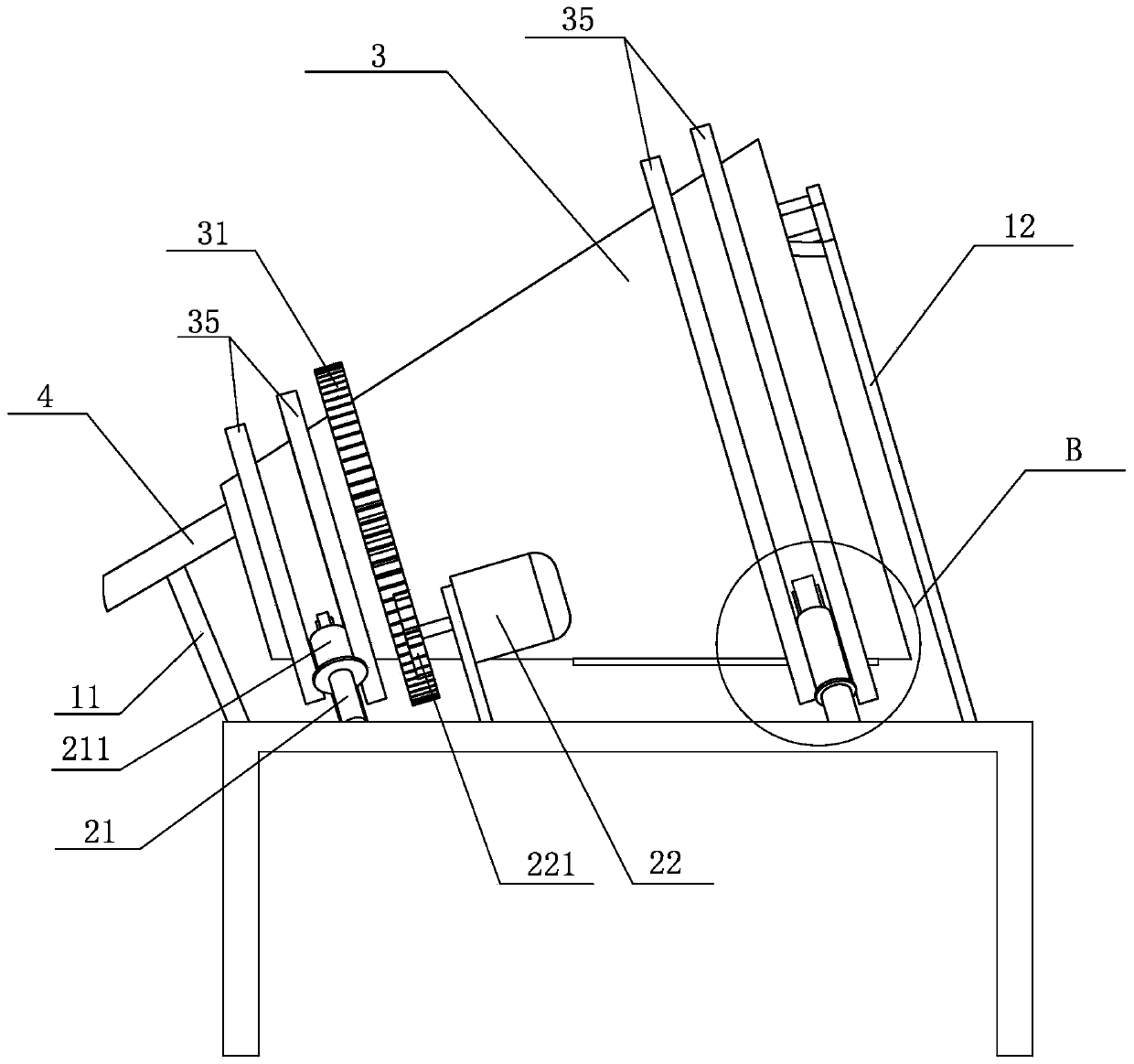

[0027] Below will combine specific embodiment and appended Figure 1-11 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

[0028] The invention provides a brake pad steel back finishing device (such as figure 1shown), including a support platform 1, a rotary support drive mechanism, a rotary cylinder 3, a steel back chute 4 and an arc steel back guard plate 5, the rotary support drive mechanism includes a rotary support leg 21 and a rotary drive motor 22, in the An annular ring gear 31 is set on the outer peripheral side wall of the rotary drum 3, and a belt slot 32 perpendicular to the inner side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com