Automatic conveying and distributing system

A diversion system and conveyor belt technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of affecting production quality, increasing the cost of automatic conveying diversion, reducing the total production volume, etc., to achieve the effect of increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

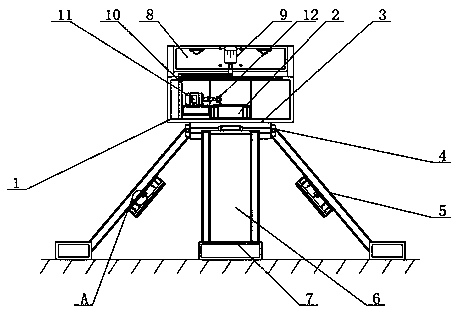

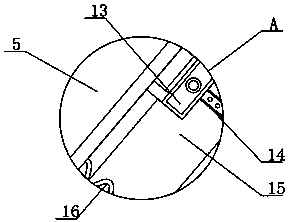

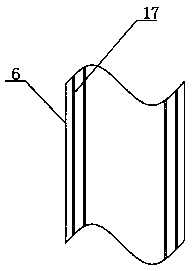

[0021] see Figure 1-5 , the present invention provides the following technical solutions: an automatic conveying and diverting system, including an outer shell 1 and a conveyor belt 2 placed inside the outer shell 1, a connecting block 3 welded on the lower surface of the outer shell 1, and a clamping block 4 arranged inside the connecting block 3 , a slide plate 6 is provided below the outer shell 1, the slide plate 6 is slidably connected to the connecting block 3 through the clamp block 4, grooves 17 are opened on both sides of the slide plate 6, and the side plates 5 are snapped and connected in the groove 17, One side of the side plate 5 is integrally formed with a pull plate 13, and a limit plate 15 is welded on the lower surface of the side plate 5 close to the position of the pull plate 13, and a limit groove 14 is opened at the middle position on the surface of the limit plate 15, and the outer shell 1 is provided with a connection plate 8, the connection plate 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com