Construction method for controlling embedded quality of foundation bolt embedded part

A construction method and technology for embedding parts, which can be used in infrastructure engineering, construction, etc., and can solve the problems of large axis and elevation deviation of large embedded parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is described in detail below:

[0020] A construction method for pre-embedded quality control of anchor bolt embedded parts is carried out according to the following steps:

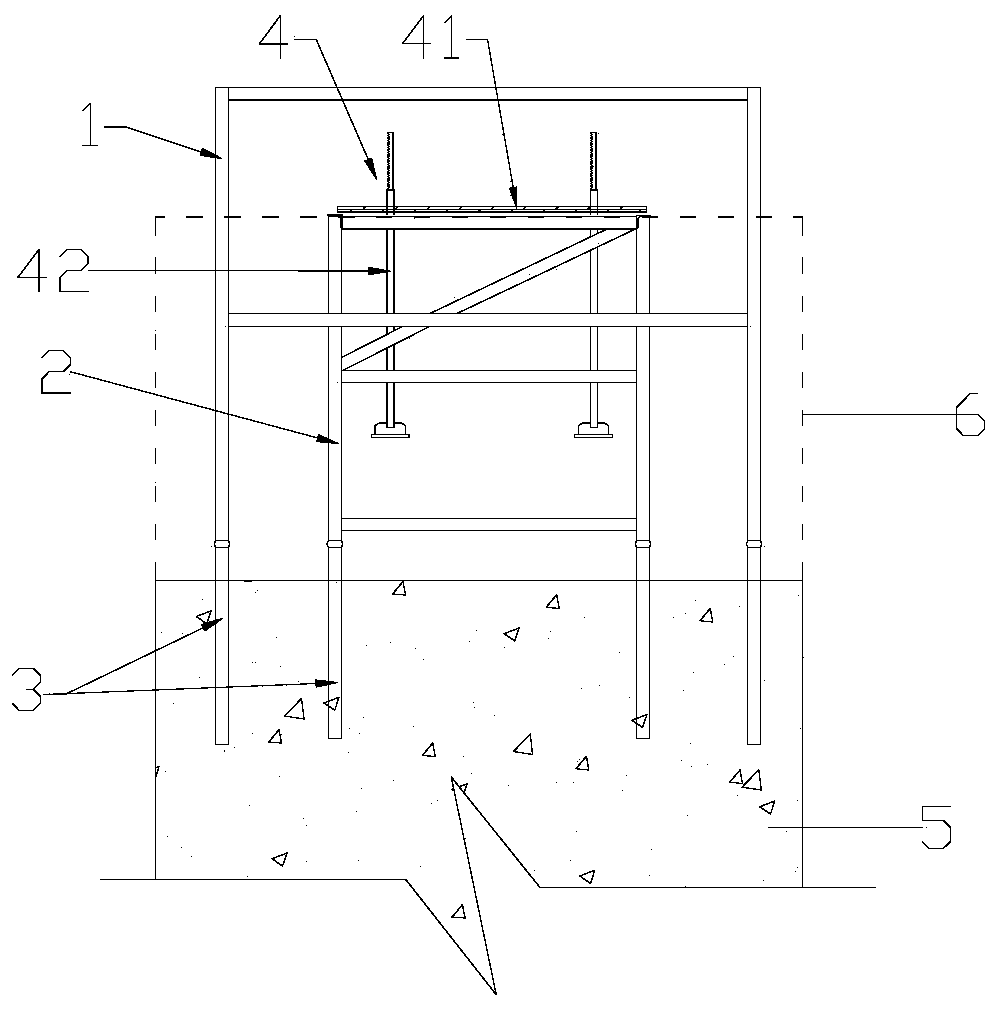

[0021] The first step: make bolt embedded parts, according to the design requirements of the drawings, carry out on-site welding or factory processing of embedded parts, and the bolt spacing, position and verticality meet the design and specification requirements. The bolt embedded part is made up of four bolt rods 41 and a steel plate 42, and the bolt hole is made on the steel plate 42, and the bolt rod 41 is installed in the bolt hole.

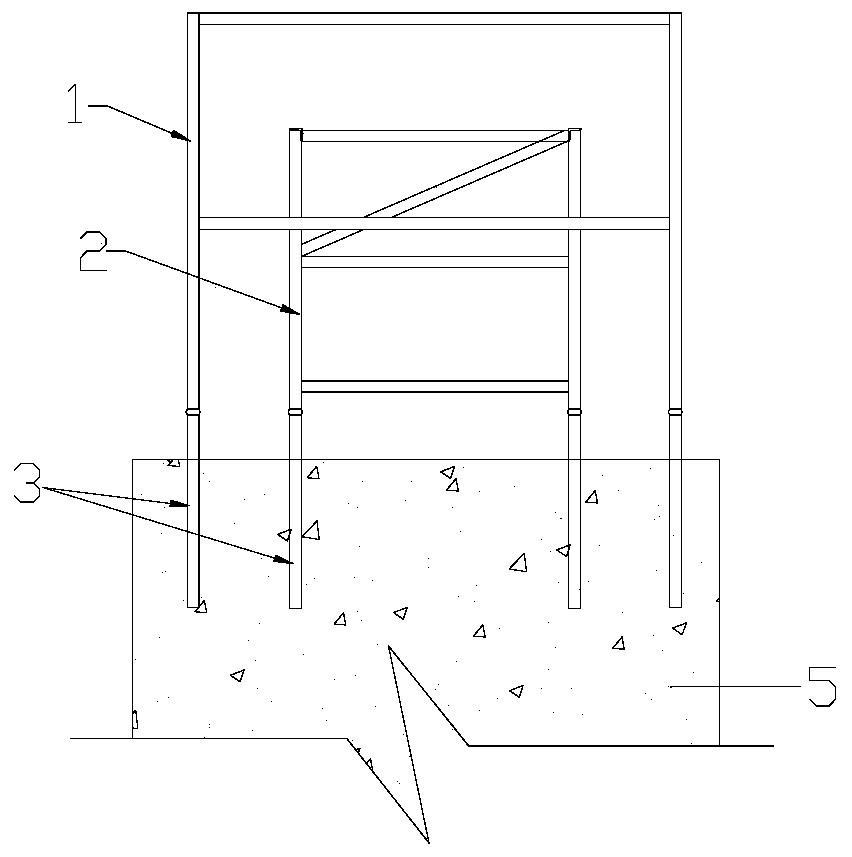

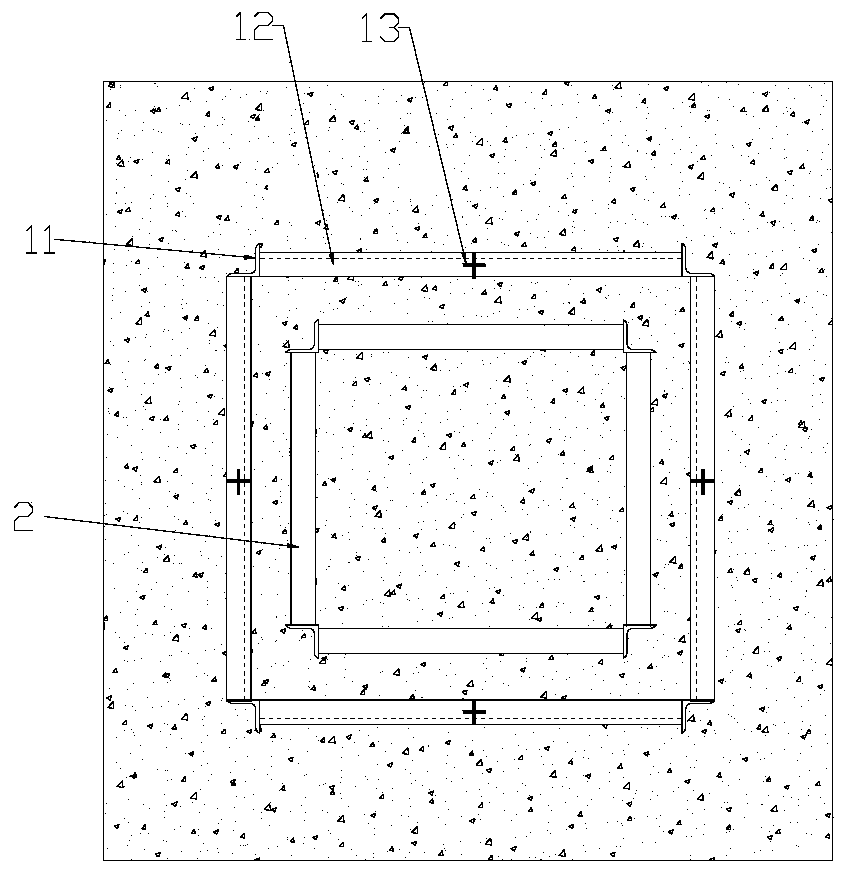

[0022] Step 2: Weld the fixing frame 2 and the wire frame 1. Wire rack 1 provided by the present invention is as Figure 1-3 As shown, four upright columns 11 are included, and the tops of the four upright columns 11 are affixed by top beams 12, and the upright columns and top beams are welded into a square frame. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com