A hydraulically adjustable time-delay opening device

A technology of hydraulic pressure and hydraulic cavity, applied in the field of hydraulic adjustable time delay opening device, can solve the problems such as the delay can not be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

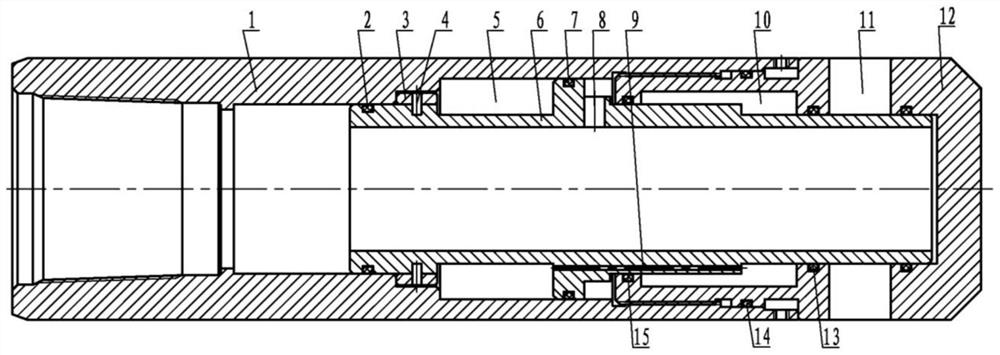

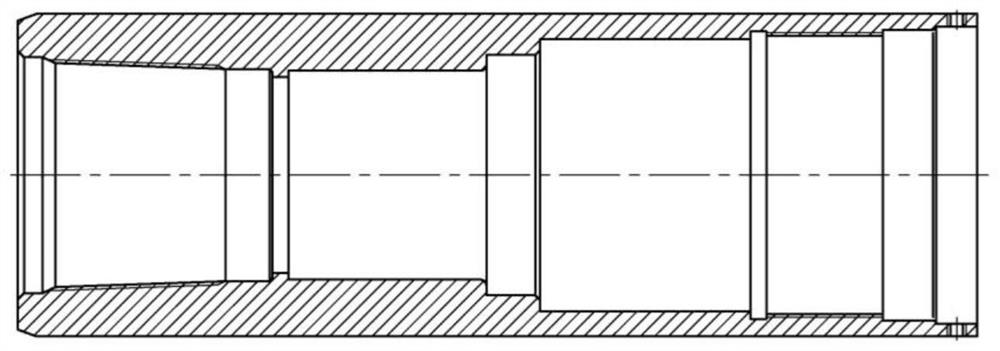

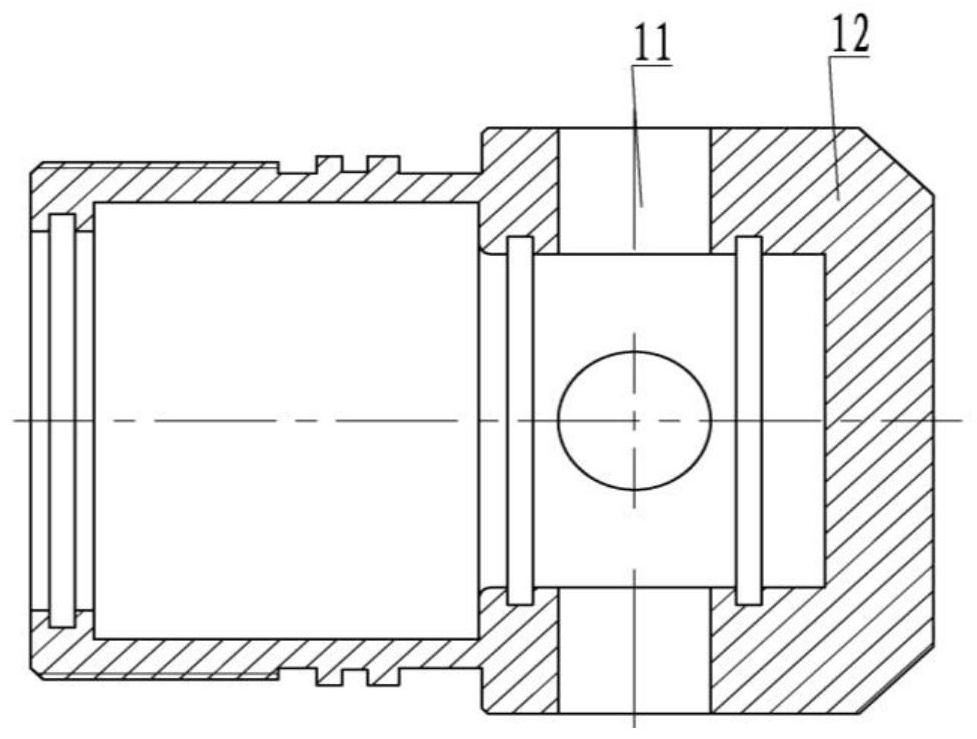

[0023] see figure 1 — Image 6 , a hydraulic adjustable time-delay opening device The device consists of an upper body 1, a first sealing ring 2, a piston ring 3, a pin 4, an upper hydraulic chamber 5, a sliding sleeve 6, a second sealing ring 7, and a pressure hole 8 , delay hole 9, lower hydraulic chamber 10, circulation hole 11, lower body 12, sealing ring 13, sealing ring 14, sealing ring 15, sealing ring 16, etc. In the construction of oil and gas wells, it realizes the function of delaying perforation in the perforation construction process.

[0024] The upper body 1 and the lower body 12 are connected by a threaded sealing structure, and the sliding sleeve 6 is fixedly assembled with the piston ring 3 through the pin 4 , and then integrally assembled in the center of the upper body 1 and the lower body 12 . Upper hydraulic chamber 5 dresses hydraulic oil capacity and is not greater than 3 / 4 of upper hydraulic chamber volume, and the volume of lower hydraulic chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com