Flashboard blowout preventer with composite side door

A ram blowout preventer and composite technology, applied in the direction of wellbore/well components, earthwork drilling, sealing/package, etc., can solve the problems of heavy side door structure, time-consuming and laborious opening and closing, and avoid mechanism jamming , reliable connection and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

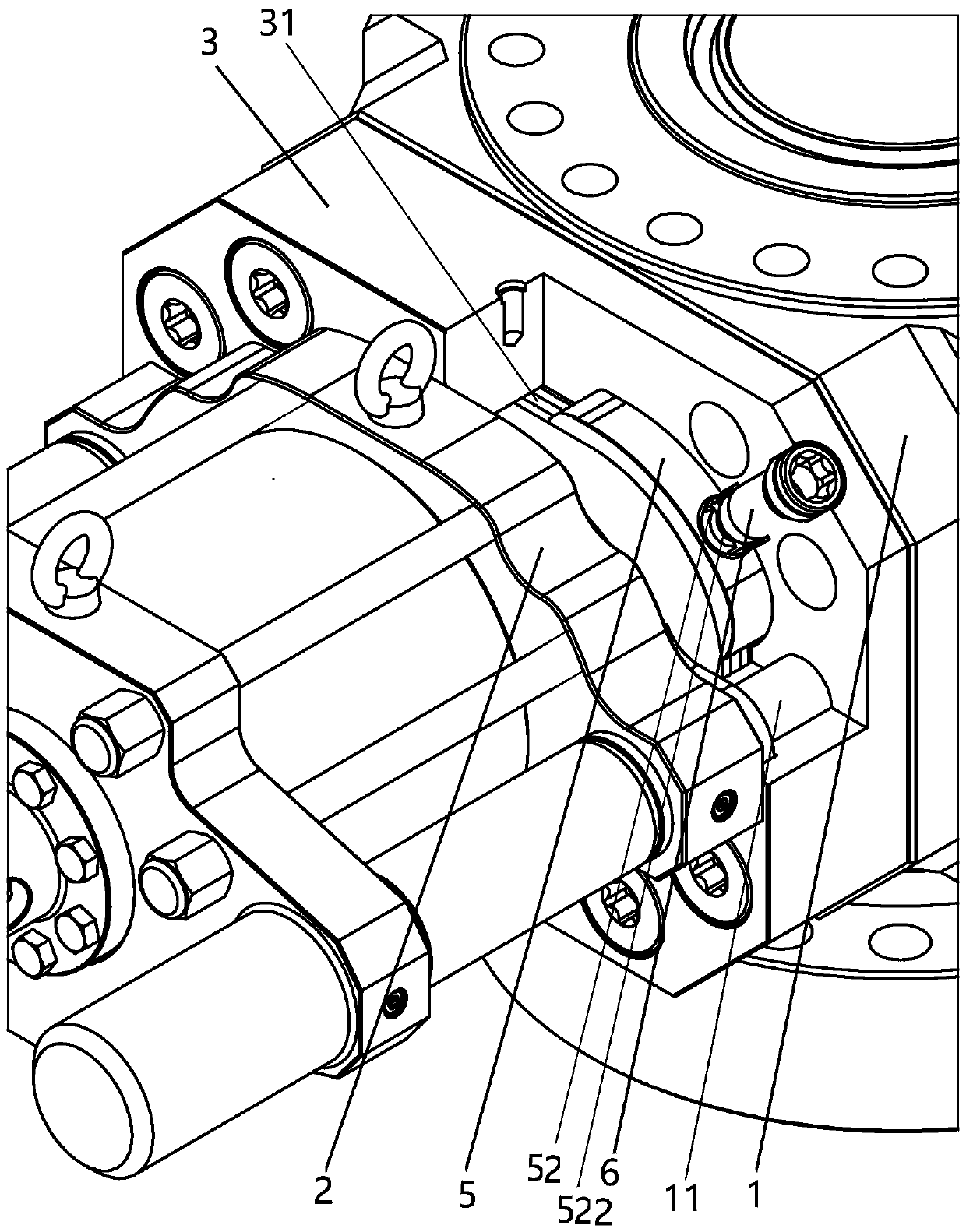

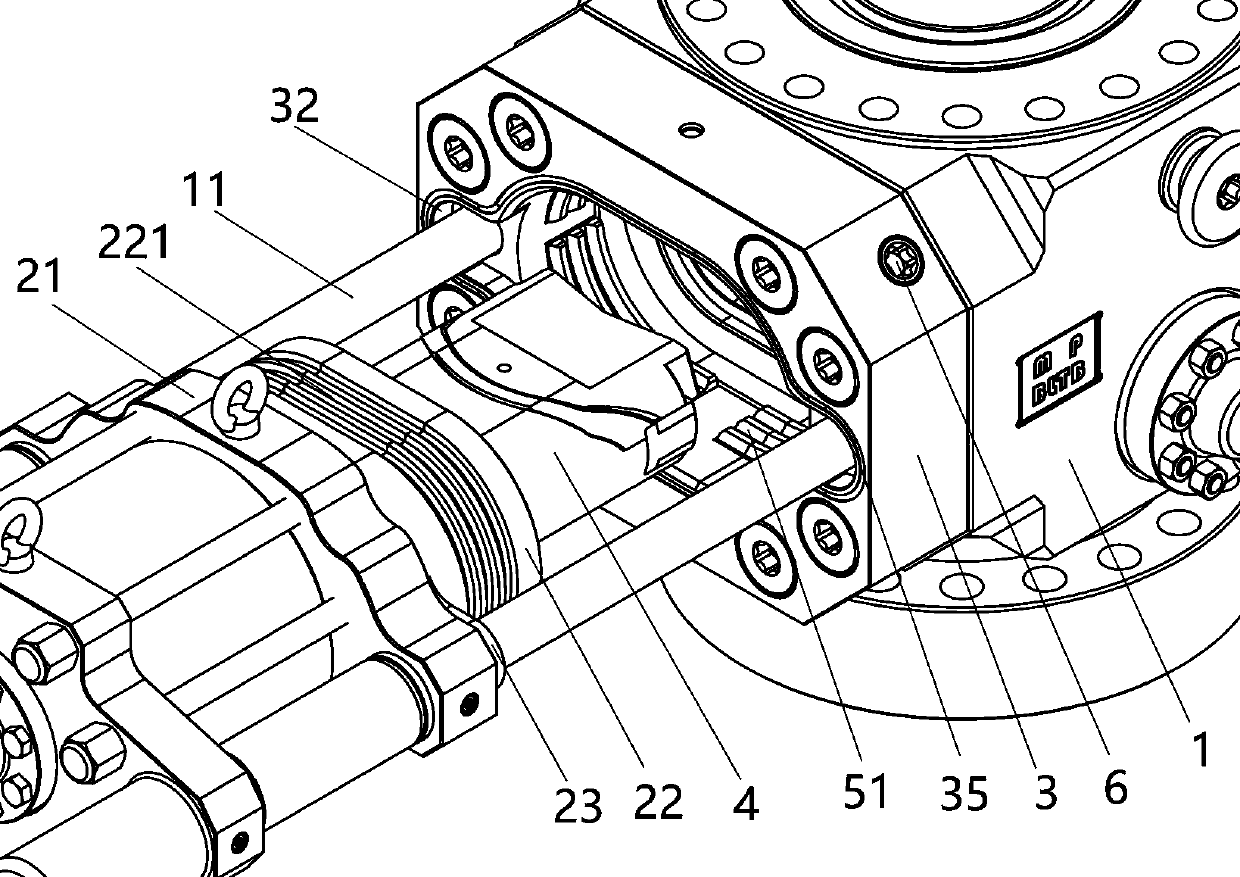

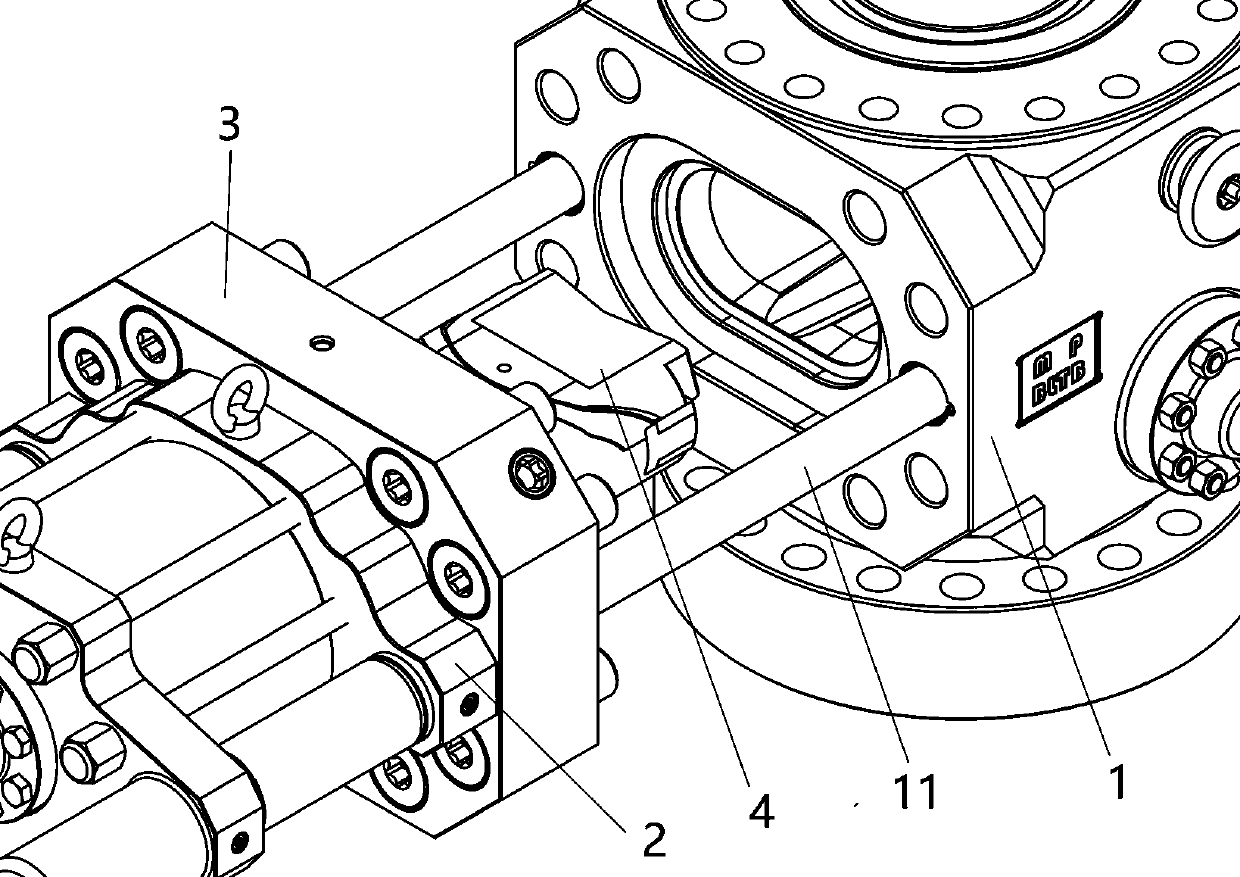

[0025] A ram blowout preventer with a composite side door, referring to the accompanying drawings, includes a shell 1 with a ram 4 built in and side doors matched to both sides of the shell 1 . The side door includes an outer door 3 and an inner door 2, and the outer door 3 is fixed on the casing 1 by bolts arranged in the axial direction. The middle part of the outer door 3 has a through cavity adapted to the front end of the inner door 2 . The inner door 2 includes a sealing seat 21 and a connecting portion 22 , a positioning lug 23 is provided at the joint of the sealing seat 21 and the connecting portion 22 , and a lug groove 32 is provided on the end surface of the outer door 3 for matching. The connecting part 22 of the inner door 2 is inserted into the through cavity of the outer door 3 , the sealing seat 21 is attached to the end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com