Accurate positioning method for sleeve puller bolt of high-speed rail contact net supporting device

A technology for supporting devices and tightening bolts, which is applied in neural learning methods, biological neural network models, image data processing, etc., can solve the problems of sensitivity to size differences, adverse effects, and impact failures, so as to achieve intelligent analysis and reduce huge work Quantity, to achieve the effect of location extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] A method for precise positioning of a socket tightening bolt of a catenary support device for a high-speed railway, comprising the following steps:

[0031] Step 1: Obtain the marked sample library of components of the high-speed rail catenary support device;

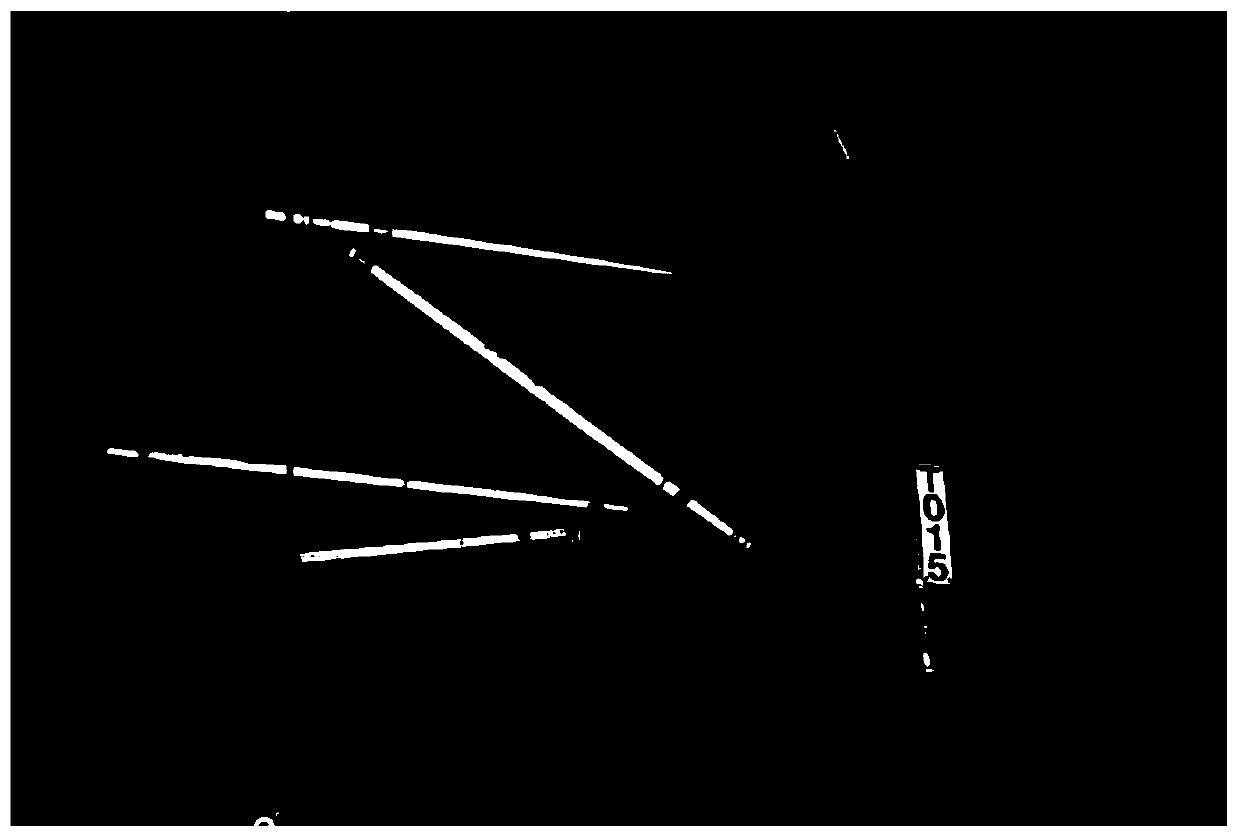

[0032] A special comprehensive train inspection vehicle is used to image the support and suspension devices of the high-speed railway catenary. The special comprehensive train inspection vehicle performs uplink and downlink high-definition image storage of the high-speed railway catenary support device at a certain operating speed. The global image is as follows: figure 1 shown.

[0033] The collected images are screened, and a labeled sample library of catenary support device components is constructed.

[0034] The Tag Sample Gallery includes images from the following categorie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com