Pressure core body utilizing boss structure sintering base

A technology of boss structure and core body, which is applied in the field of sensitive components, can solve problems such as glue overflow and affect the performance of pressure chips, and achieve the effects of bearing pressure evenly, improving output accuracy, and protecting chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

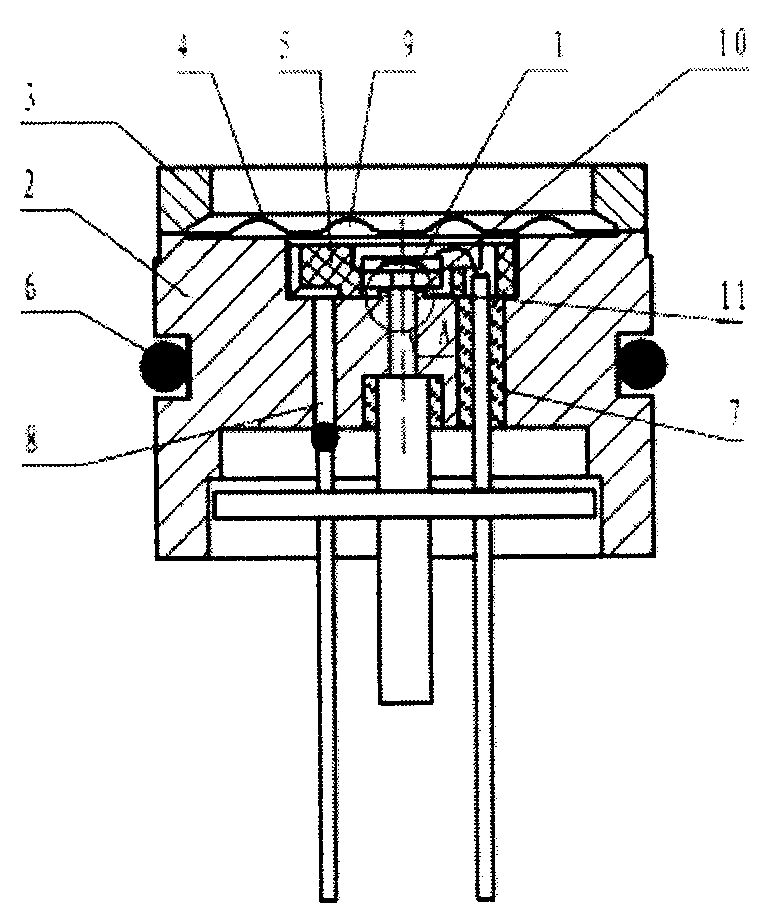

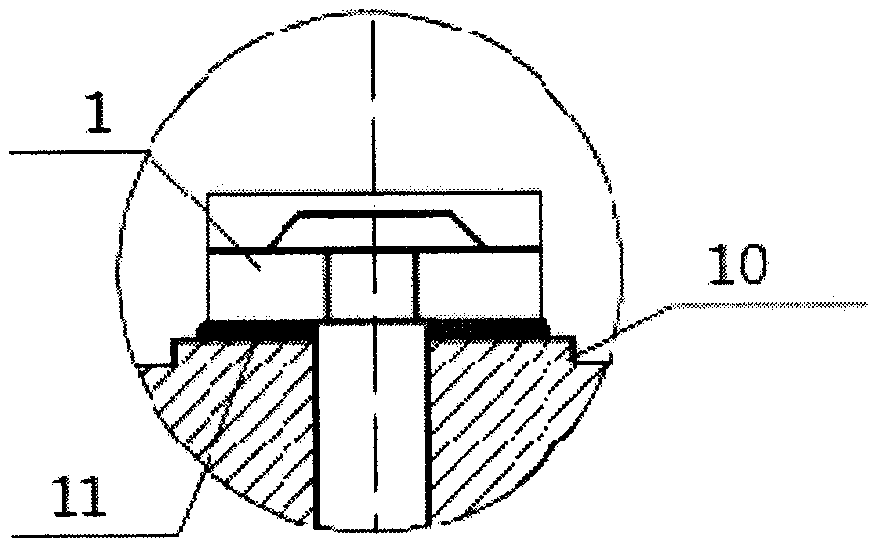

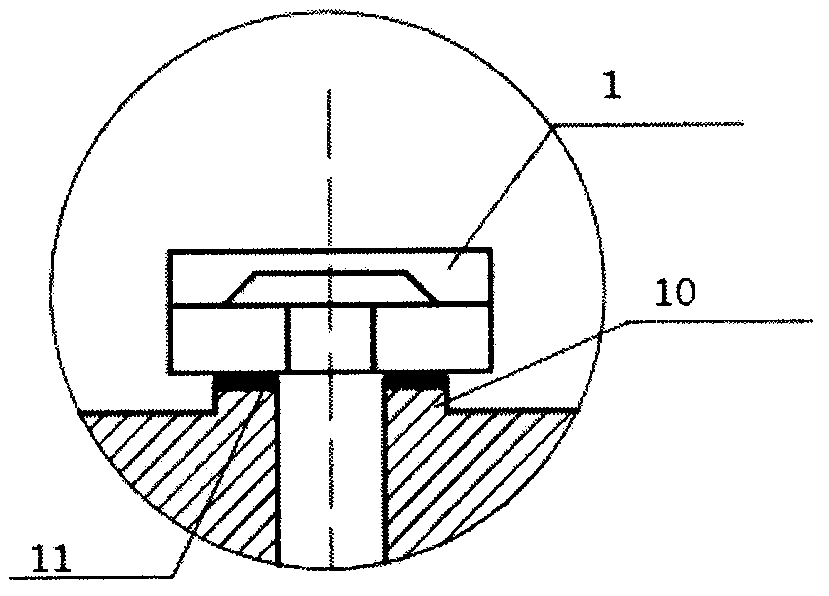

[0018] refer to figure 1 , a pressure core with a sintered base with a boss structure, including a chip (1), a sintered base (2), a pressure ring (3), a diaphragm (4), a ceramic pad (5), and an O-ring (6) , a glass insulator (7), the sintered base (2) is provided with an oil filling hole (8), the filling oil (9) can be poured into the cavity of the core body through the oil filling hole (8), and the pressure ring ( 3), the diaphragm (4) is connected to the sintered base (2) by welding, the sintered base (2) has a boss (10) structure, and the area of the bottom surface of the boss (10) is the same as that of the chip (1) The bottom surface area differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com