Cooling fin fixing mechanism of chip, cooling device and installation method of cooling fin fixing mechanism

A fixing mechanism and heat dissipation device technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of damaging the core of the chip, achieve the effect of protecting the chip and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

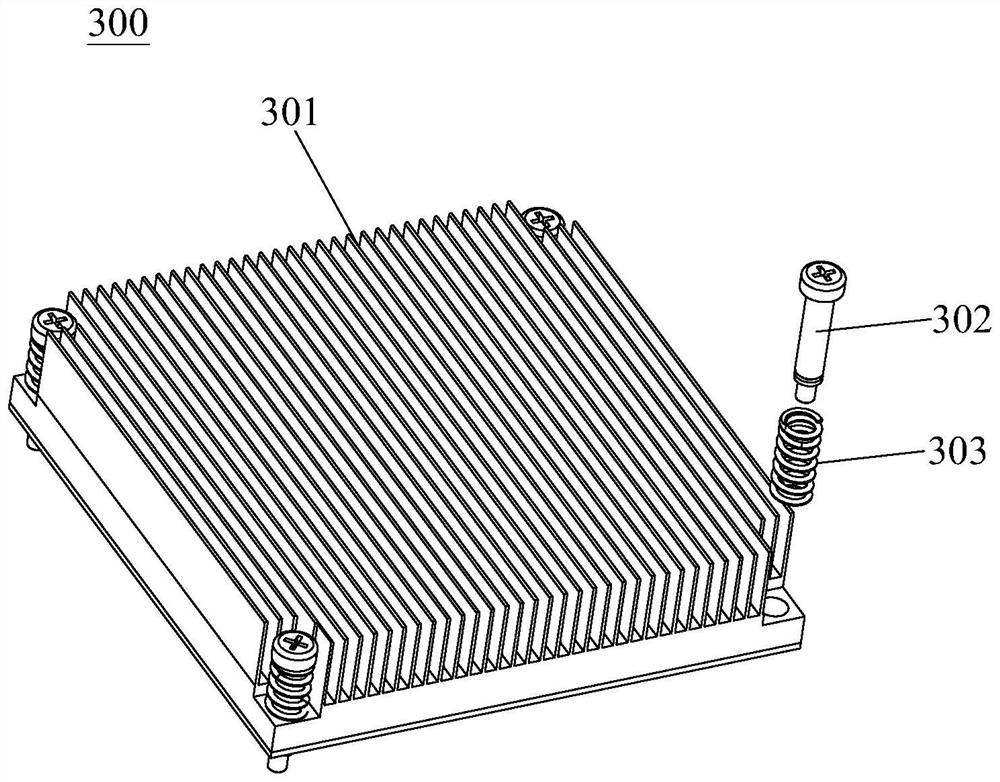

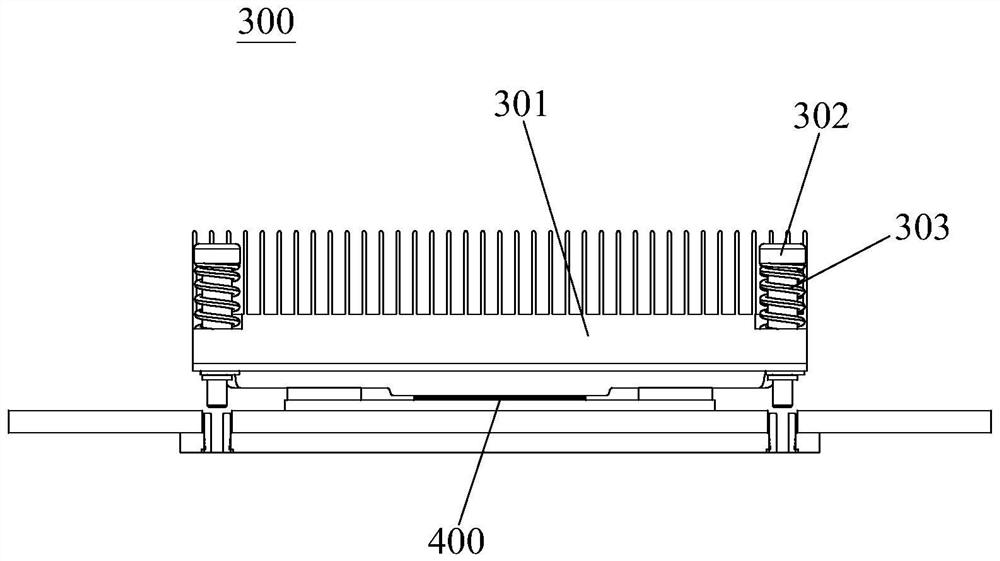

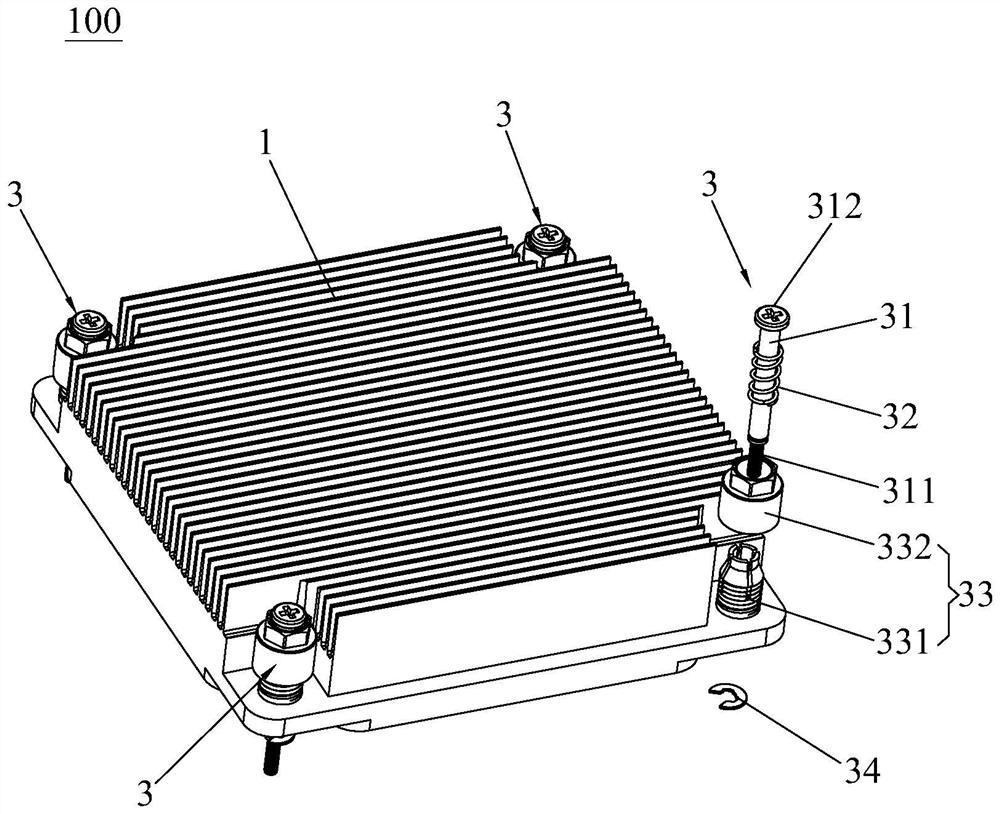

[0027] like image 3 and Figure 4 As shown, the heat dissipation device 100 of the present invention is used to dissipate heat from the chip 201, which includes a heat sink 1, a fixed bracket 2 and a heat sink fixing mechanism 3, the chip 201 is arranged on a PCB 200, and the PCB 200 is placed on the fixed bracket 2, the heat sink 1 is arranged above the fixed support 2 and pressed on the chip 201. The heat sink fixing mechanism 3 is connected between the fixed support 2 and the heat sink 1, so that the heat sink 1 is positioned on the fixed support 2, and the chip 201 and the PCB 200 are placed against the heat sink 1 by the heat sink 1. Press on the fixed bracket 2. Specifically, the heat sink fixing mechanisms 3 are distributed around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com