Joint cutting mechanism for road construction and joint cutting machine

A technology for road construction and seam cutting, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of low construction efficiency and low cutting efficiency, and achieve the effect of wide application range and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

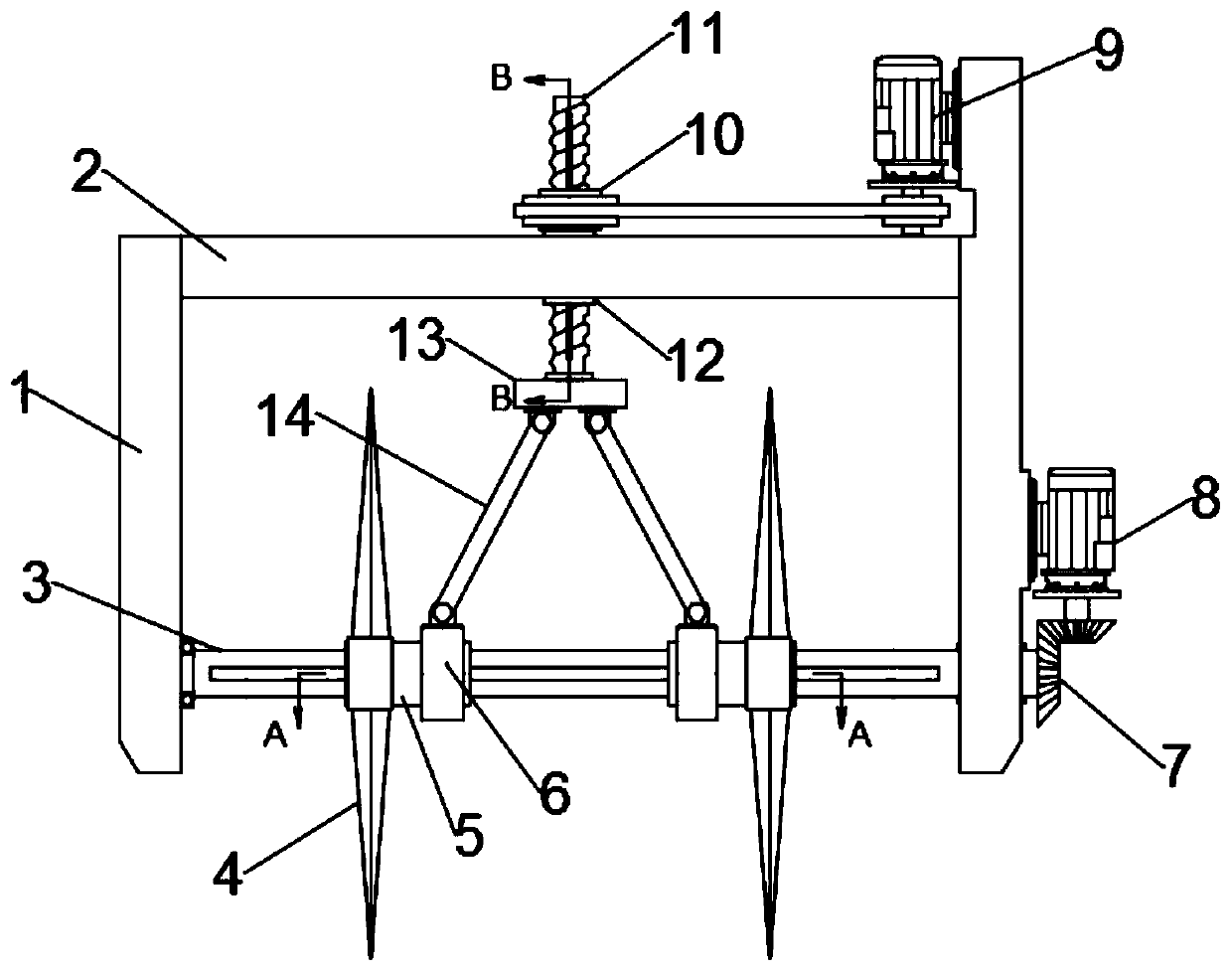

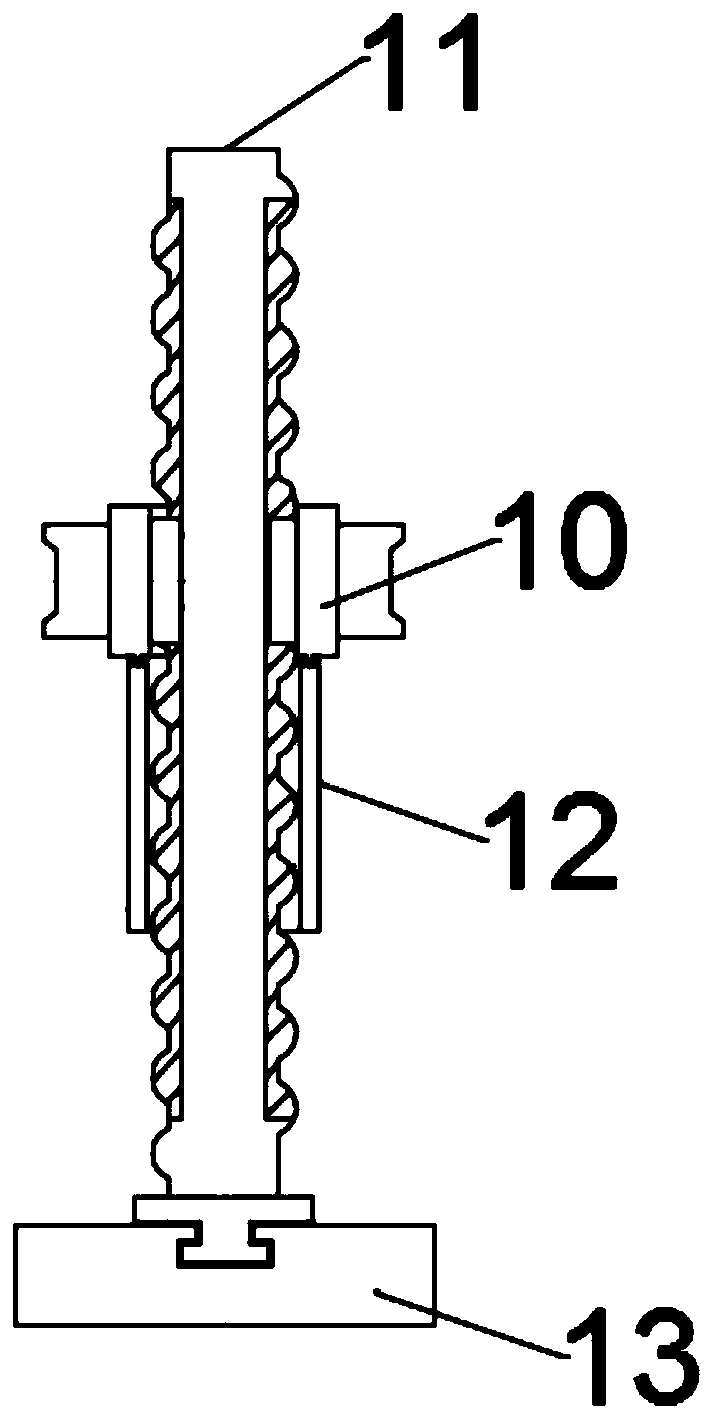

[0024] see Figure 1~4 , in an embodiment of the present invention, a slitting mechanism for road construction includes two side plates 1 arranged symmetrically; There is a rotating shaft 3 driven by the drive assembly, and the rotating shaft 3 is sleeved with a sleeve 5 that can only slide horizontally along it and is used for fixing the cutting knife 4, and the sleeve 5 is arranged symmetrically with respect to the central axis of the rotating shaft 3 There are two, and the rotating ring 6 hinged with the adjustment assembly is installed on the sleeve 5. When the adjustment assembly is triggered, the two sleeves 5 move toward each other or move oppositely, thereby realizing the distance adjustment between the two cutting knives 4, To achieve different cutting requirements, a wide range of applications.

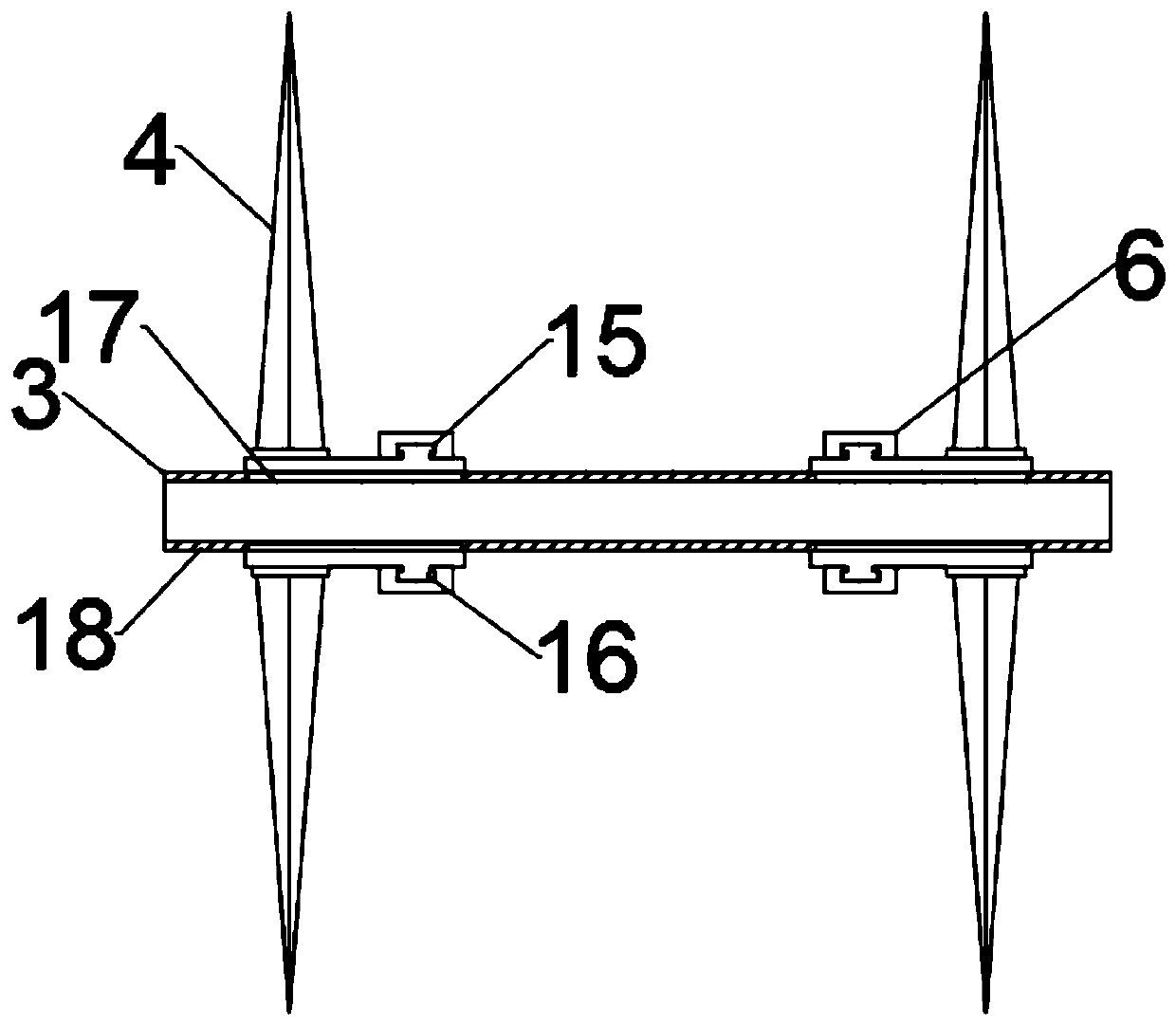

[0025] At least one bar-shaped stop block 17 is fixed on the inner wall of the above-mentioned sleeve 5, and the bar-shaped stop block 17 is slidably fitted with the bar-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com