Dust collector floor brush with function of adjusting height of dust collecting holes

A technology for vacuum cleaners and vacuum cleaners, which is applied to vacuum cleaners, suction nozzles, household appliances, etc. It can solve the problems that different types of floors cannot be cleaned, the requirements for openings are different, and small parts are easy to be lost. It is simple to install, easy to use, and Not easy to lose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

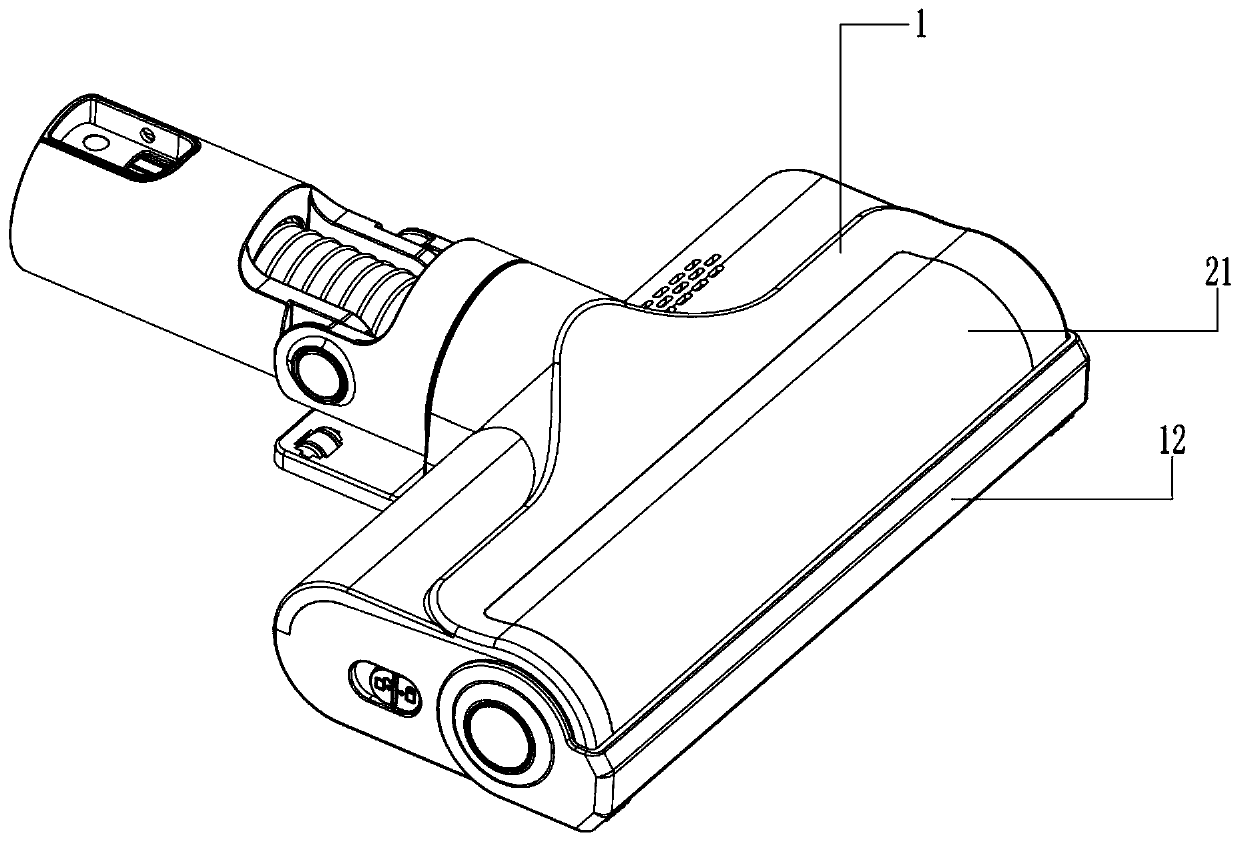

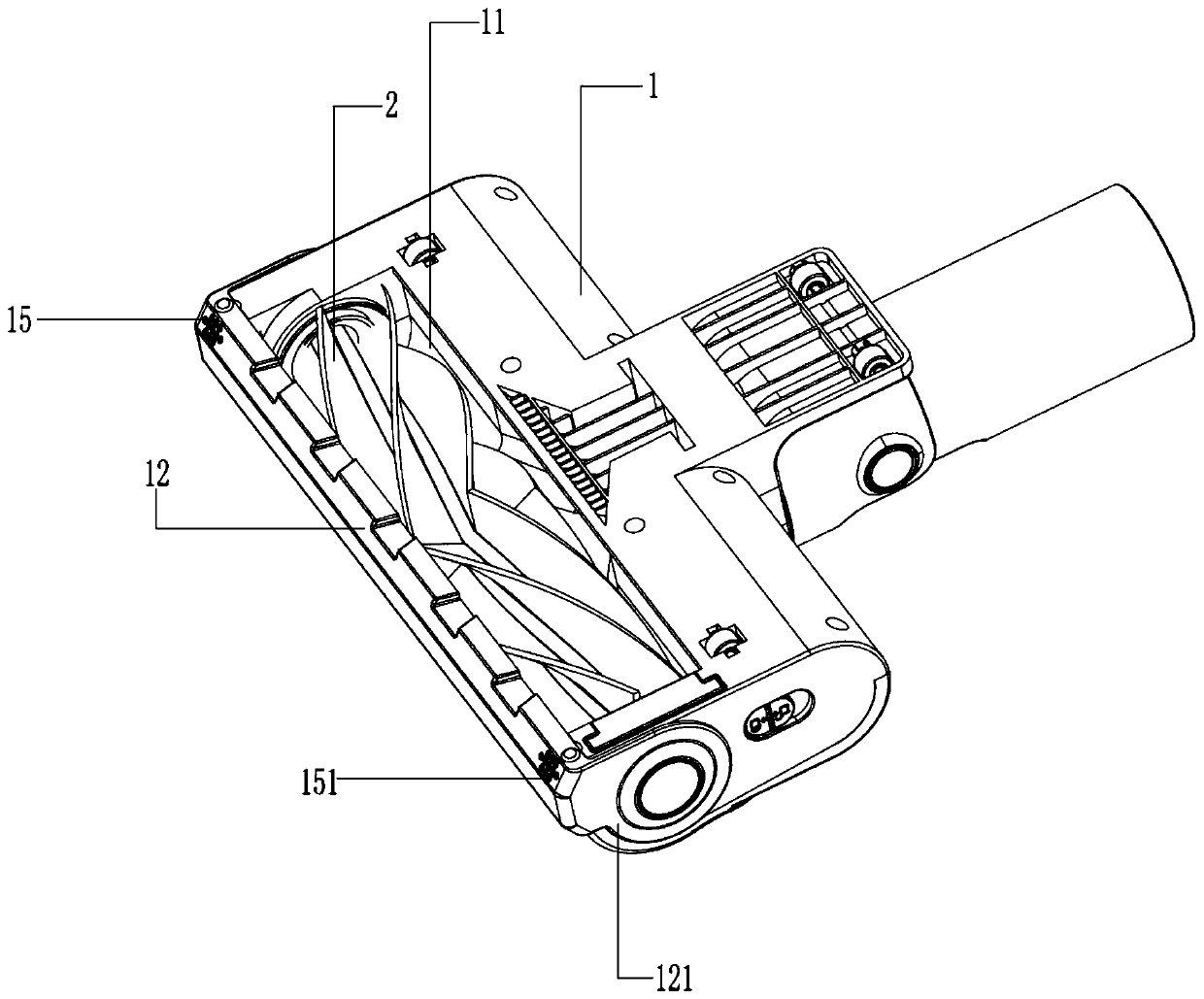

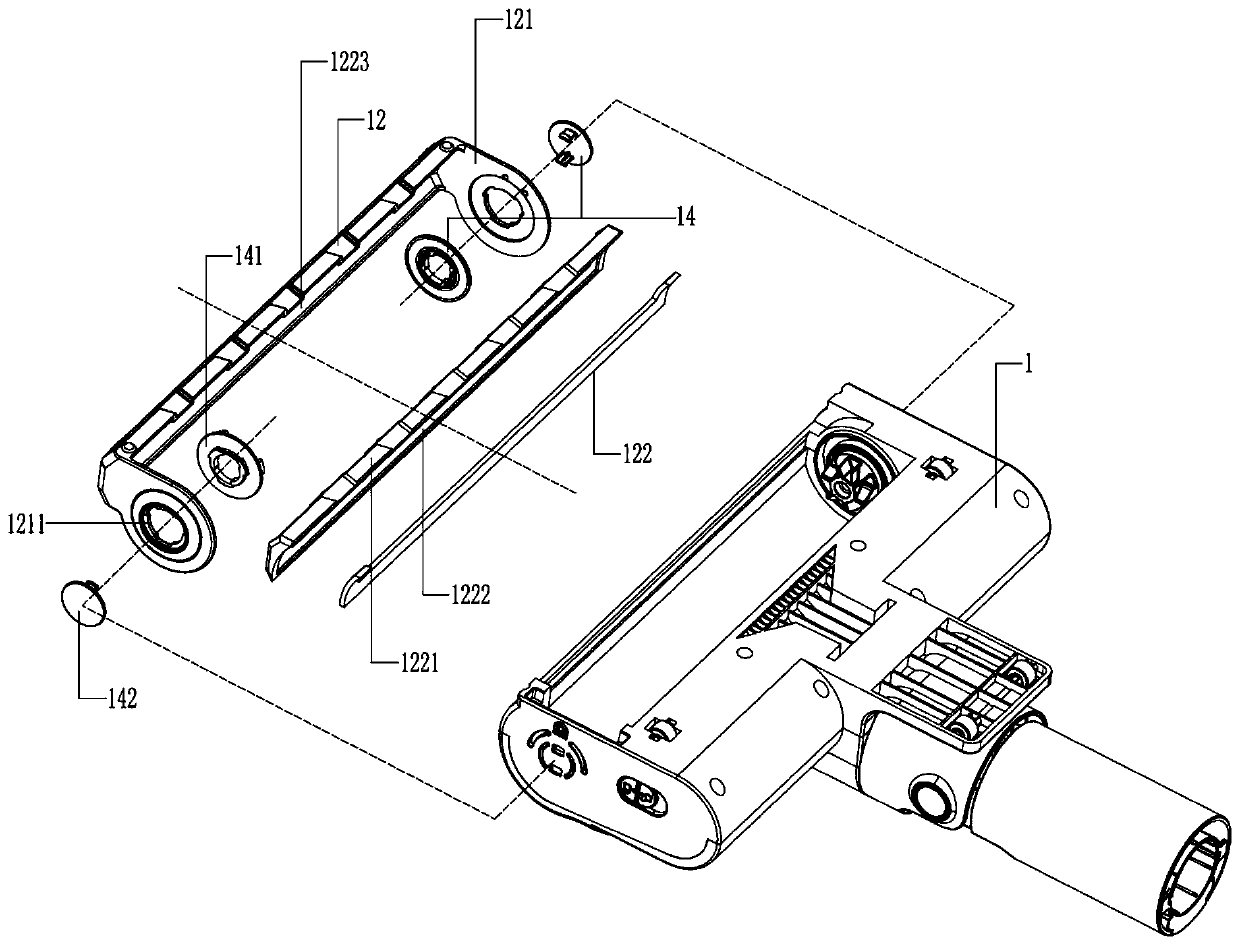

[0033] see Figure 1 to Figure 4 , the figure shows a floor brush of a vacuum cleaner with adjustable suction port height provided by Embodiment 1 of the present invention, which includes a floor brush body 1, a rolling brush 2 and a rolling brush cover 21, and the cross section of the rolling brush cover 21 is Arc-shaped, the roller brush 2 is a fluff roller brush, and the roller brush 2 is fixedly installed on the preset roller brush chamber 11 on the floor brush body 1. The inner wall of the plate 12 is an arc surface, the length direction of the suction port adjustment plate 12 is parallel to the axial direction of the roller brush 2, and the opposite ends of the width direction of the dust suction port adjustment plate 12 face the roller brush cover 21 and the ground brush body respectively. The bottom dust suction port 13 of 1 extends, and the dust suction port regulating plate 12 can be turned along the circumferential direction of the roller brush 2.

[0034] Specific...

Embodiment 2

[0037] see Figure 5 , the figure shows a vacuum cleaner floor brush with an adjustable suction port height provided by Embodiment 2 of the present invention. Others are the same as Embodiment 1, except that the roller brush 2 is a flocking roller brush, which is used to clean carpets Dust and particles on the ground such as bare floors, and reset the adjustment plate of the suction port by 2-3.5MM (such as Figure 5 In H2), increase the vacuum degree of the air inlet of the tufting roller brush nozzle to improve the cleanliness.

Embodiment 3

[0039] see Figure 1 to Figure 5 , the figure shows a vacuum cleaner floor brush with an adjustable suction port height provided by Embodiment 3 of the present invention, which further makes the following improvements on the basis of the above-mentioned embodiment: the inner wall of the suction port adjustment plate 12 A sealing strip 122 is fixedly connected to the top, and its cross-section is arc-shaped. The sealing strip 122 extends along the length direction of the dust suction port adjustment plate 12. Specifically, the sealing strip 122 is installed in the installation compartment 1222 in the sealing strip installation shell 1221. The sealing strip installation shell 1221 is fixedly installed in the installation cavity 1223 in the adjustment plate 12 of the dust suction port. Through the setting of the above structure, the function of air sealing to the dust suction port can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com