A pipe cutting machine

A cutting machine and pipe technology, applied in metal sawing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the versatility of cutting machines, and achieve the effect of easy and convenient collection process, stable transmission and stable collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

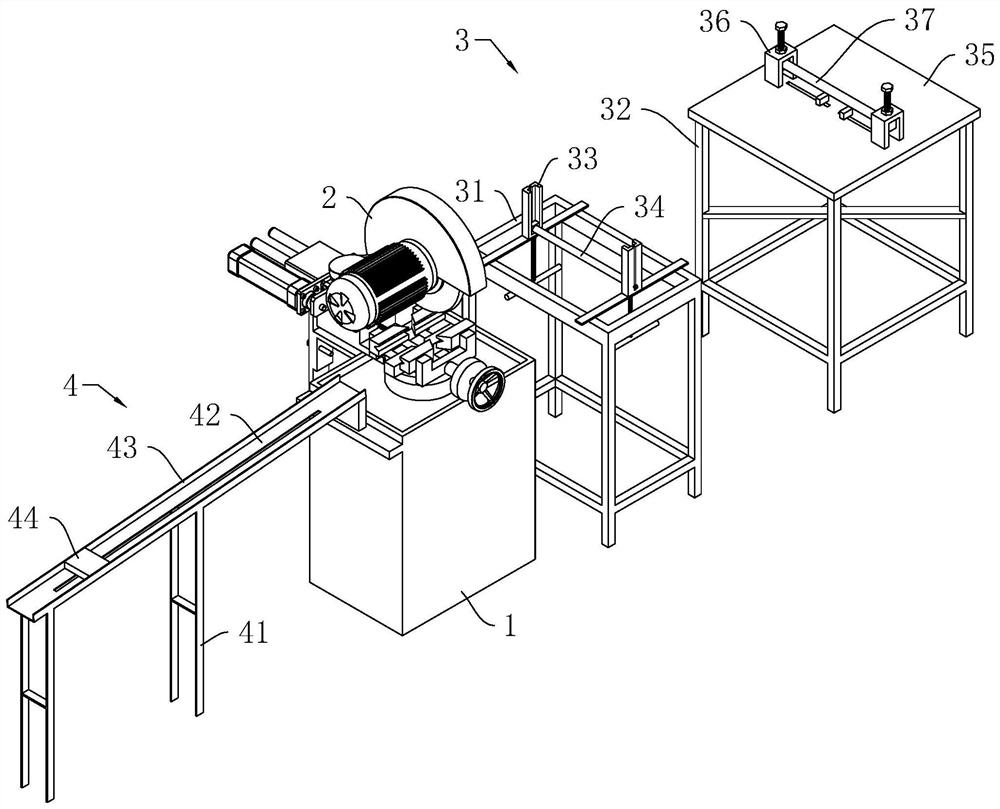

[0039] Such as figure 1 As shown, a pipe cutting machine includes a cutting table 1, a cutting saw 2 arranged on one side of the cutting table 1, a feeding mechanism 3 is provided on one side of the cutting table 1, and a discharging mechanism 4 is provided on the other side.

[0040] When using the above-mentioned cutting machine, after the pipe is transported to the position of the cutting table 1 by the feeding mechanism 3, the pipe is cut by the saw blade on the cutting saw 2, and the cut pipe is sent out along the discharge mechanism 4, thereby realizing Continuous cutting of pipes.

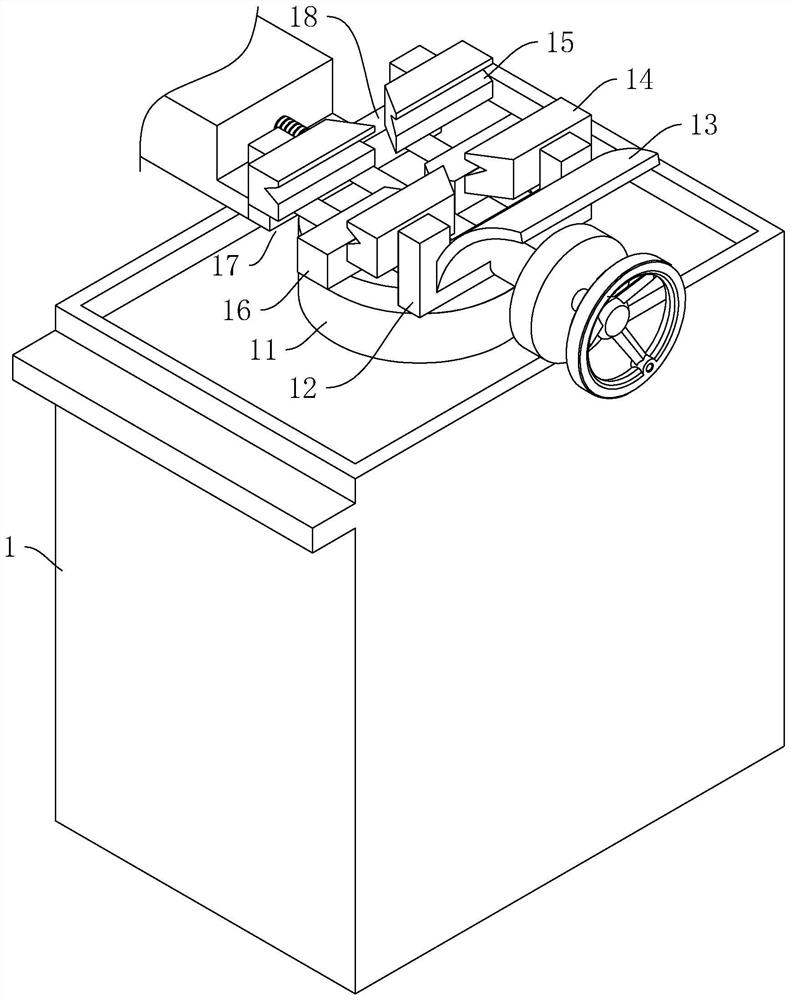

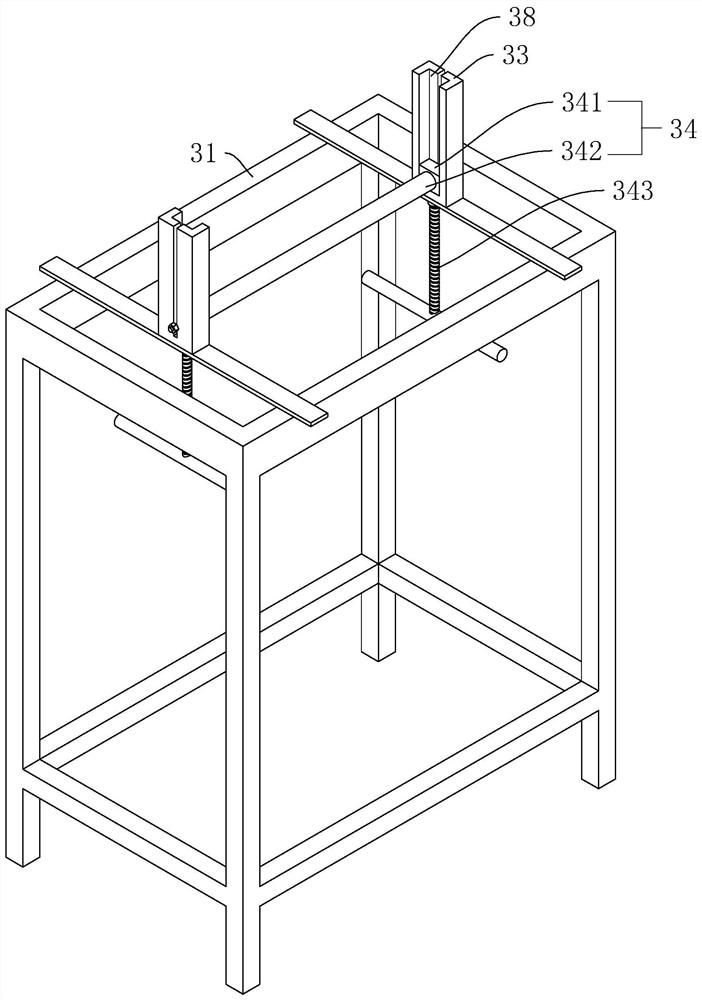

[0041] Such as figure 1 , figure 2 As shown, the cutting table 1 is provided with a support base 11, the support base 11 is provided with a vise 12, the end of the vise 12 away from the cutting saw 2 is provided with a guide plate 13, the lower end of the guide plate 13...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap