A roll paper automatic paper cutter

A paper cutter and roll paper technology, applied in metal processing and other directions, can solve the problems of high cost, low cutting efficiency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

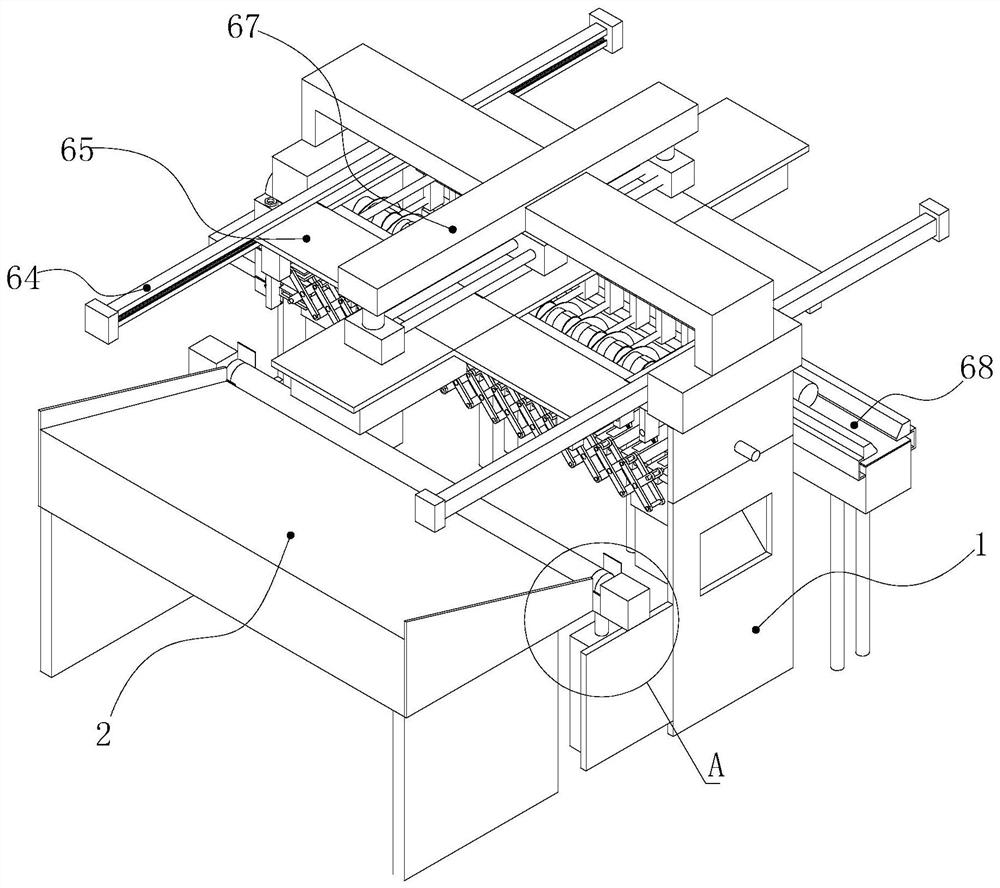

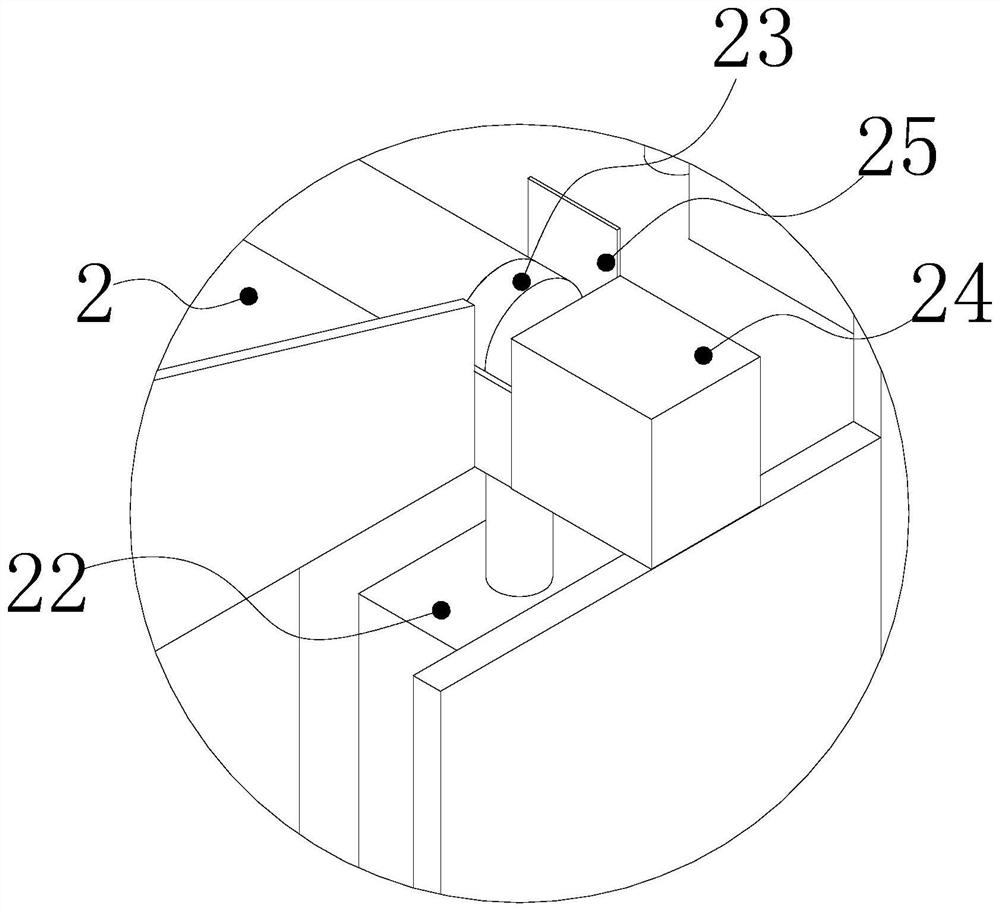

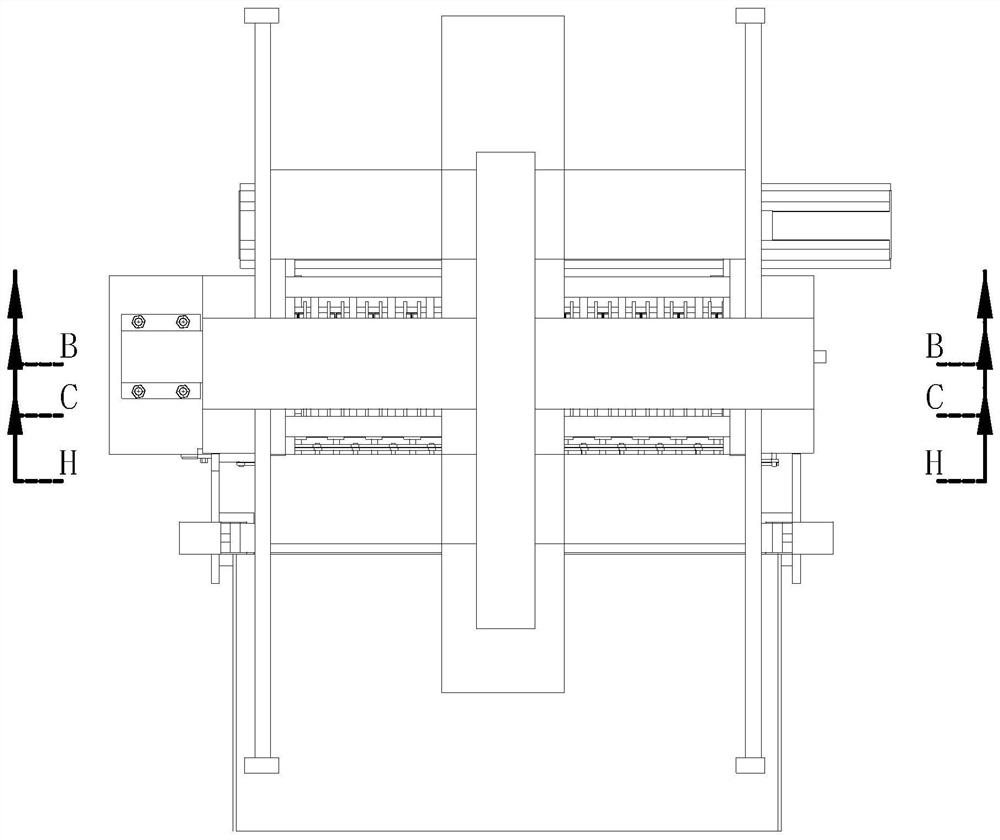

[0027] Such as Figure 1-13 As shown, an automatic web cutter includes a frame 1, a feeding device, a feeding device, a cutting device and a conveying device, and the feeding device includes a blanking plate 2, a fixed block 21, and a fixed block driver 22 , push plate 23, push plate driver 24 and baffle plate 25, the described blanking plate 2 is arranged obliquely by a support, and the described fixing block 21 is symmetrically arranged on both sides of the lower end of the blanking plate, and its upper surface is provided with an arc Groove, the push plate driver 24 is a conventional cylinder, its output end is fixed on the bottom of the fixed block 21, and the baffle plate 25 is fixed on the fixed block 21 to prevent the raw material from rolling out of the arc groove, then The raw material can be rolled directly to the fixed block through the tilted blanking plate. Since the fixed block is provided with an arc-shaped groove, the raw material will be directly stuck into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com