Attachment jig and attachment method using attachment jig

A bonding jig and bonding technology, applied in chemical instruments and methods, lamination devices, control lamination, etc., can solve the problem of uneven thickness of liquid glue, poor control of liquid glue fluidity, and warpage of optical film surface And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

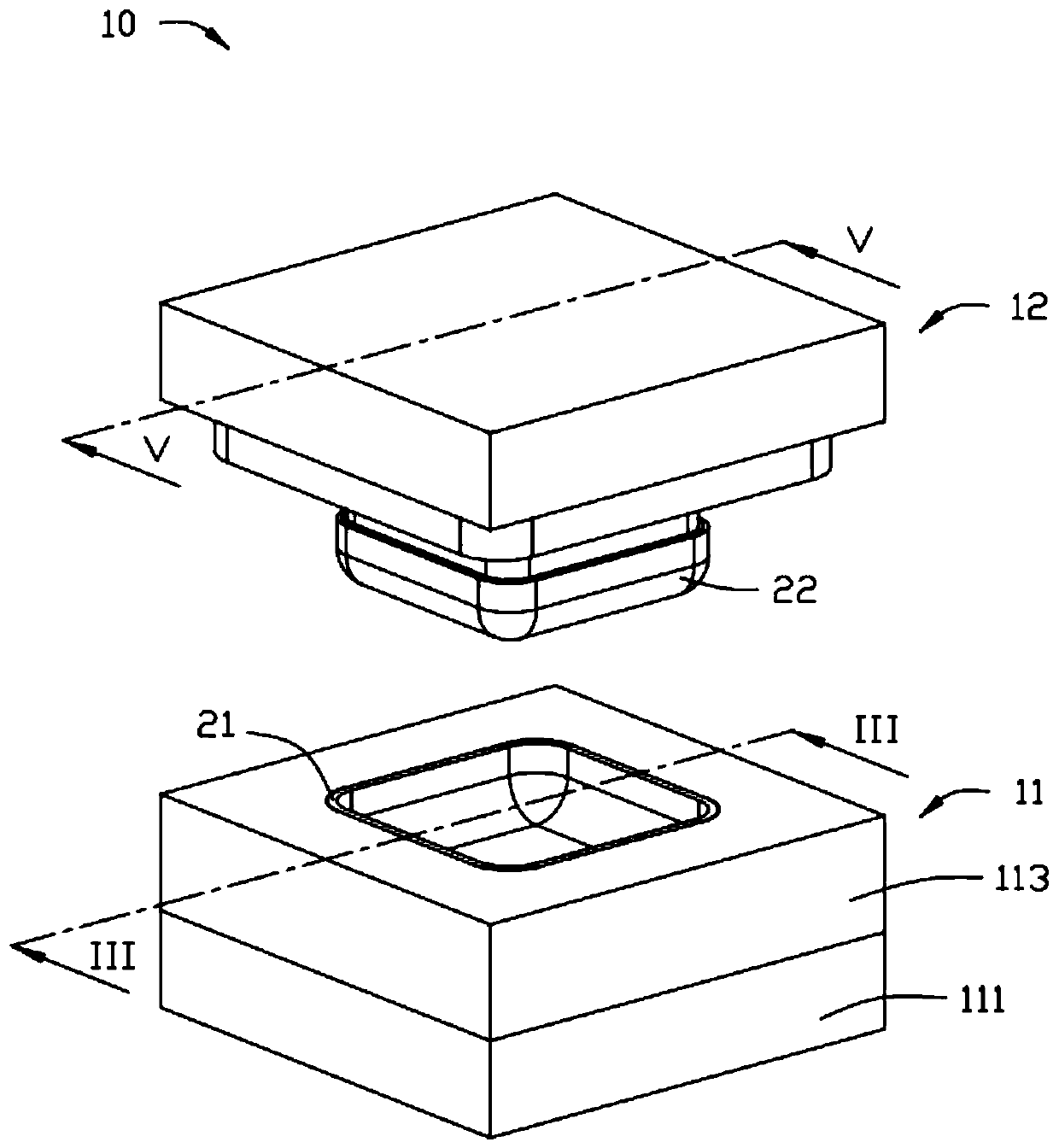

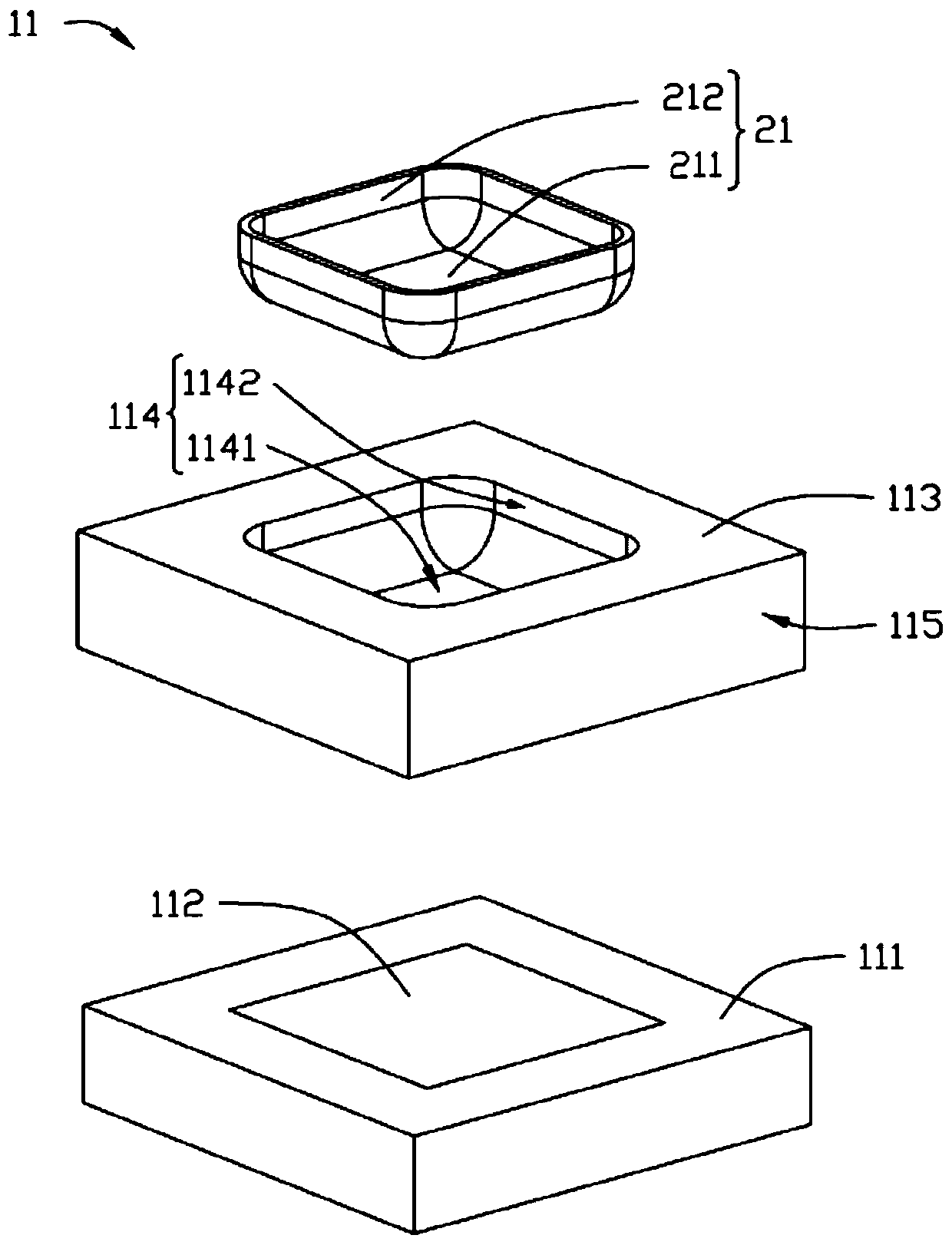

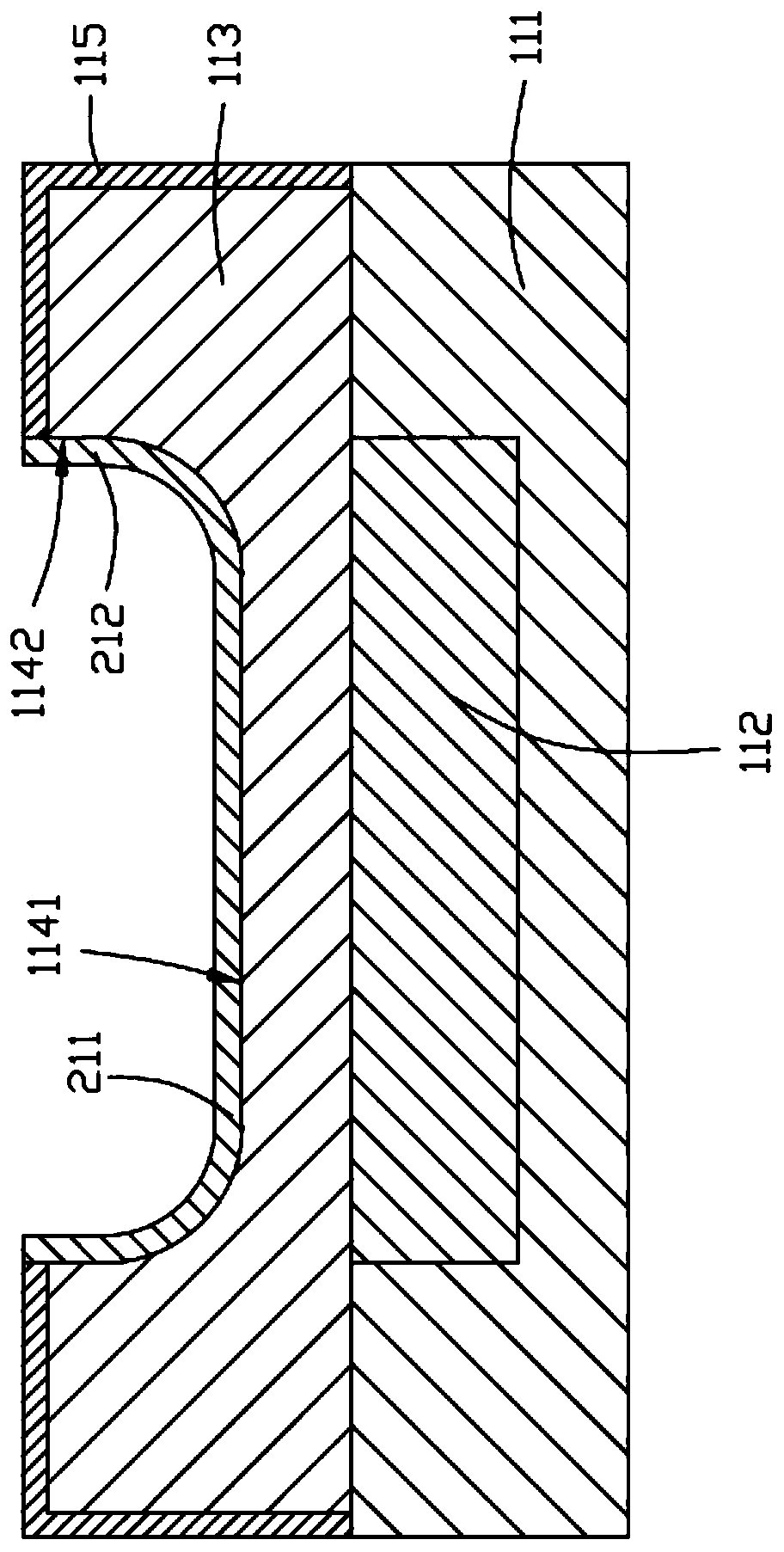

[0026] see figure 1 , the bonding jig 10 provided in this embodiment is used for bonding between workpieces, such as the bonding between the protective cover and the display panel in the display device, the bonding between the protective cover and the optical film, etc., And it is especially applicable to the situation where liquid glue is used to attach the above-mentioned objects.

[0027] read on figure 1 , the bonding jig 10 includes a first bonding portion 11 and a second bonding portion 12 separated from each other. The first bonding part 11 is used to carry the first object to be bonded 21 , and the second bonding part 12 is used to fix the second object to be bonded 22 . When the laminating jig 10 is used, the side of the first laminating part 11 carrying the first object to be bonded 21 is oppositely arranged, and usually one of the first laminating part 11 and the second laminating part 12 can be fixed, Fitting is done by moving the other one. In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com