Split type broadband steel rail damping vibration reduction noise reducer

A vibration and noise reduction, split-type technology, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of difficult continuous and synchronous arrangement of vibration and noise reduction devices, unfavorable vibration and noise reduction effects, uneven sleeper spacing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

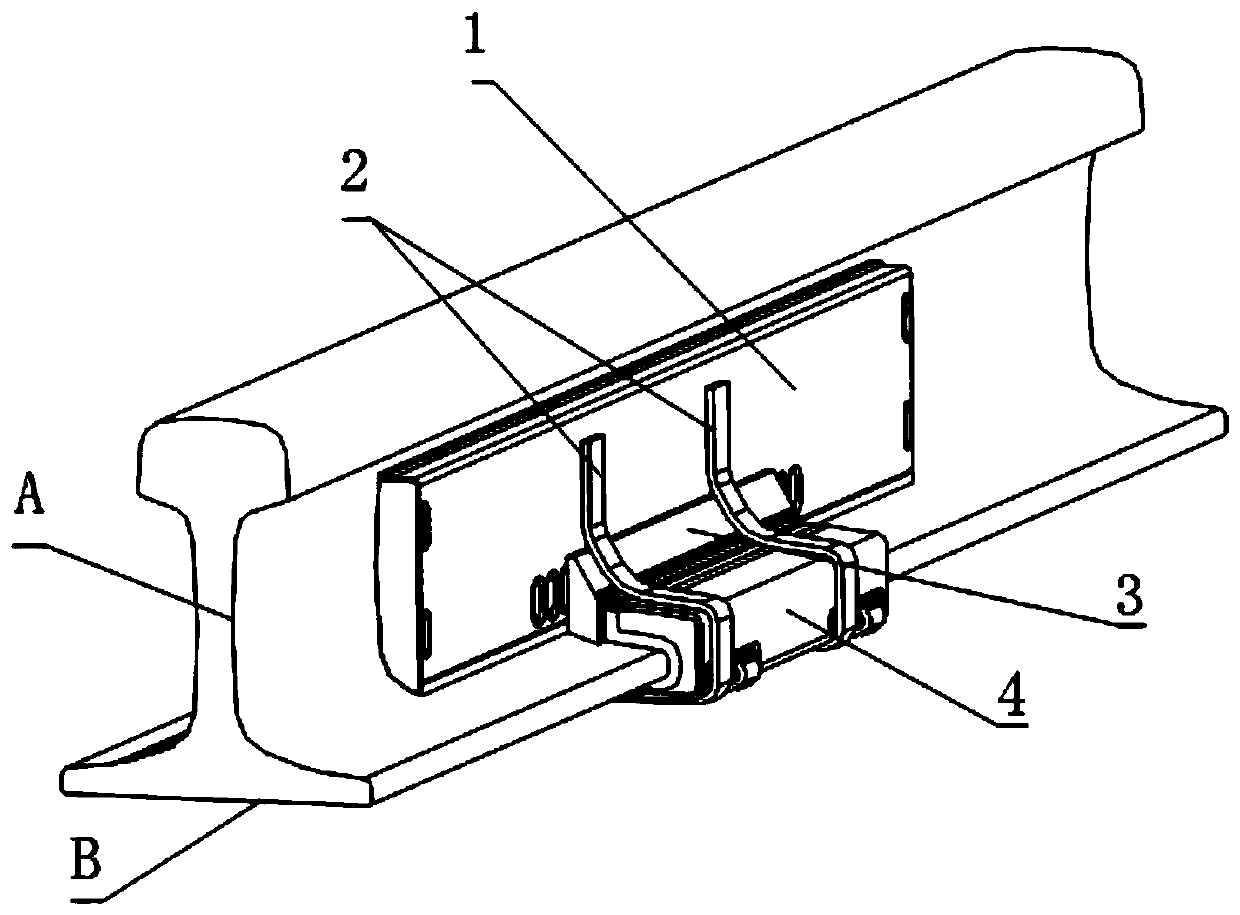

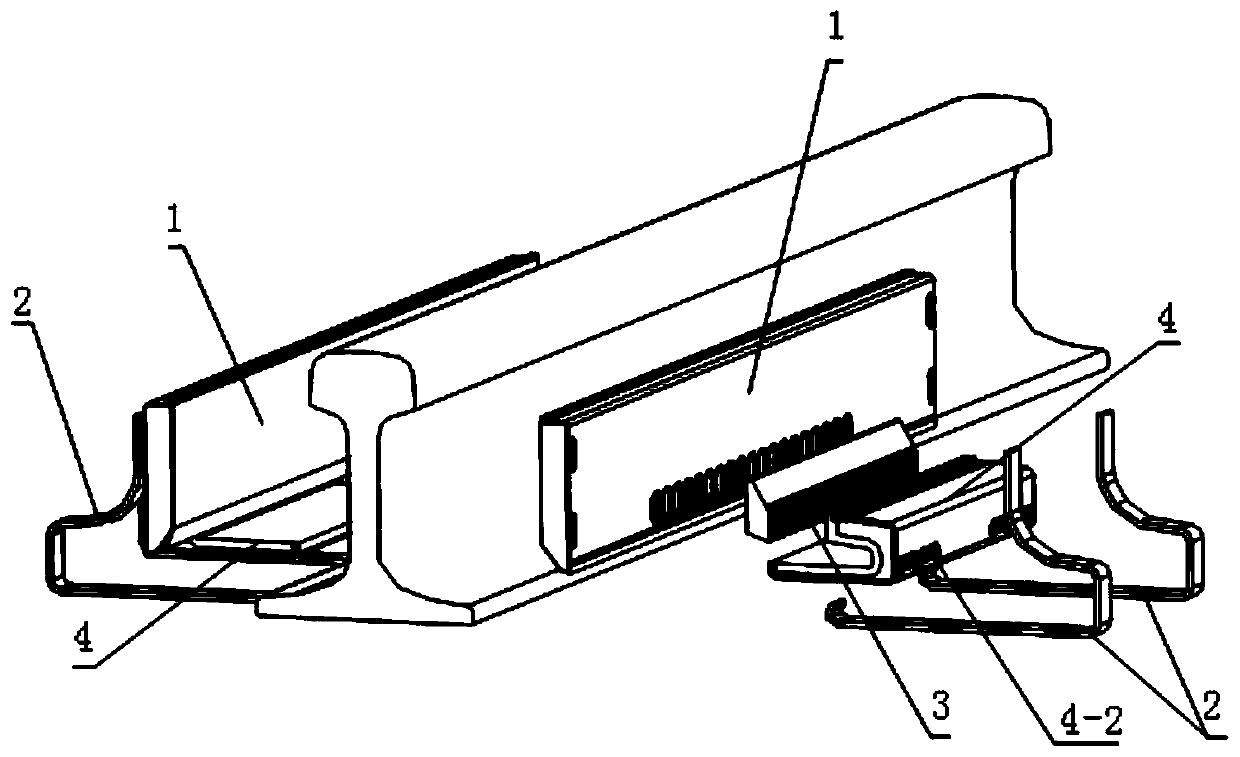

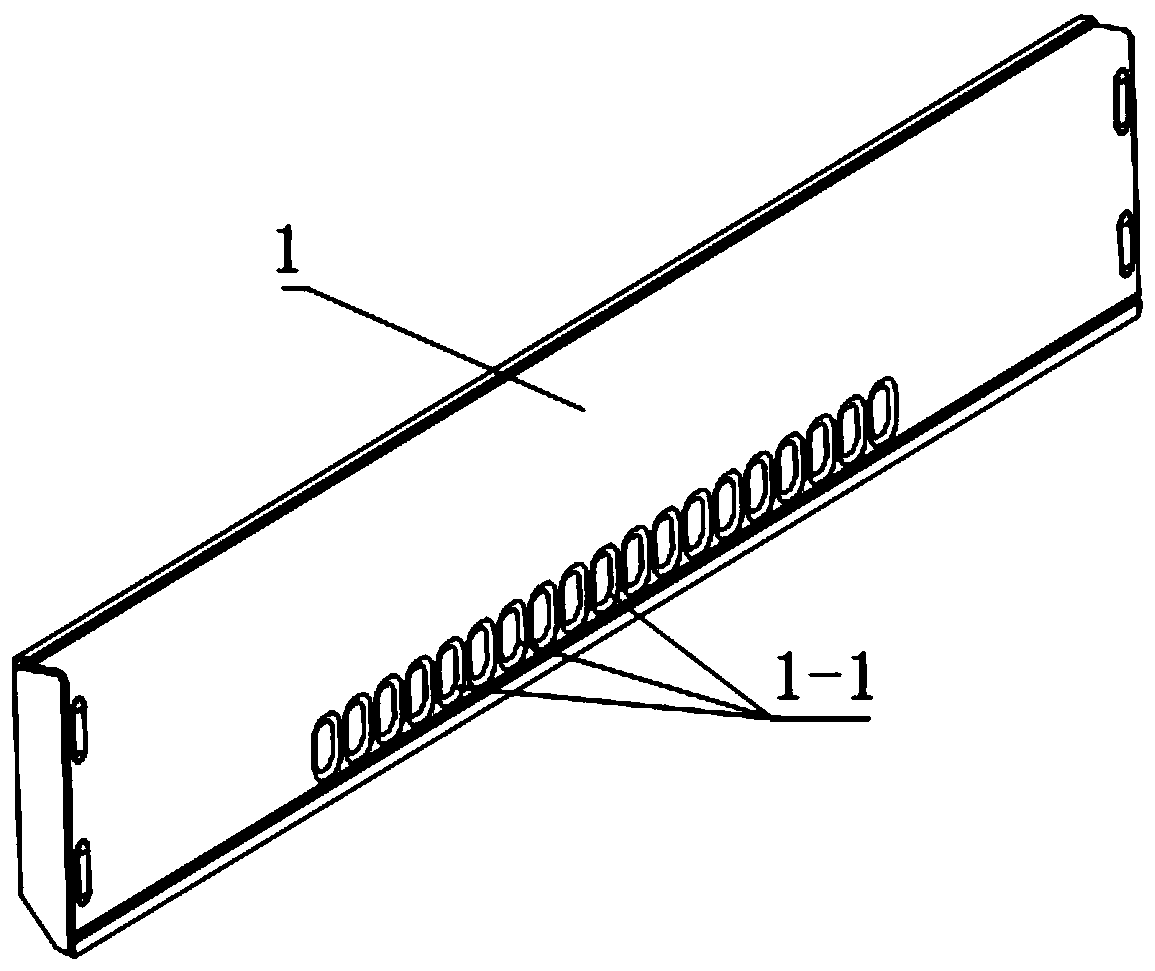

[0016] Such as figure 1 and figure 2 The rail damping vibration damping noise reducer shown includes a rail waist damping plate 1 , an intermediate adjustment block 3 , a rail bottom damping vibration absorber 4 and a snap spring 2 . The rail waist damping plate 1 is attached to the rail waist A to reduce vibration and noise on the rail waist. The entire rail is fully covered by several rail waist damping plates 1 spliced together. The middle adjustment block 3 and the rail The waist damping plate 1 is in contact, the rail bottom damping shock absorber 4 is covered on the rail bottom B part and is in contact with the middle adjustment block 3, and the rail bottom damping shock absorber 4, the middle adjustment block 3 and the rail waist damping plate 1 Clamped on the rail. Wherein the middle adjusting block 3 and the rail bottom damping shock absorber 4 are only arranged between two sleepers and do not need to cover the whole section of the rail.

[0017] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com