Thin-walled part micro-vibration measurement method and system based on motion amplification optical flow tracking

A vibration measurement and optical flow tracking technology, which is used in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, image data processing, etc. Convenient, high spatial resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

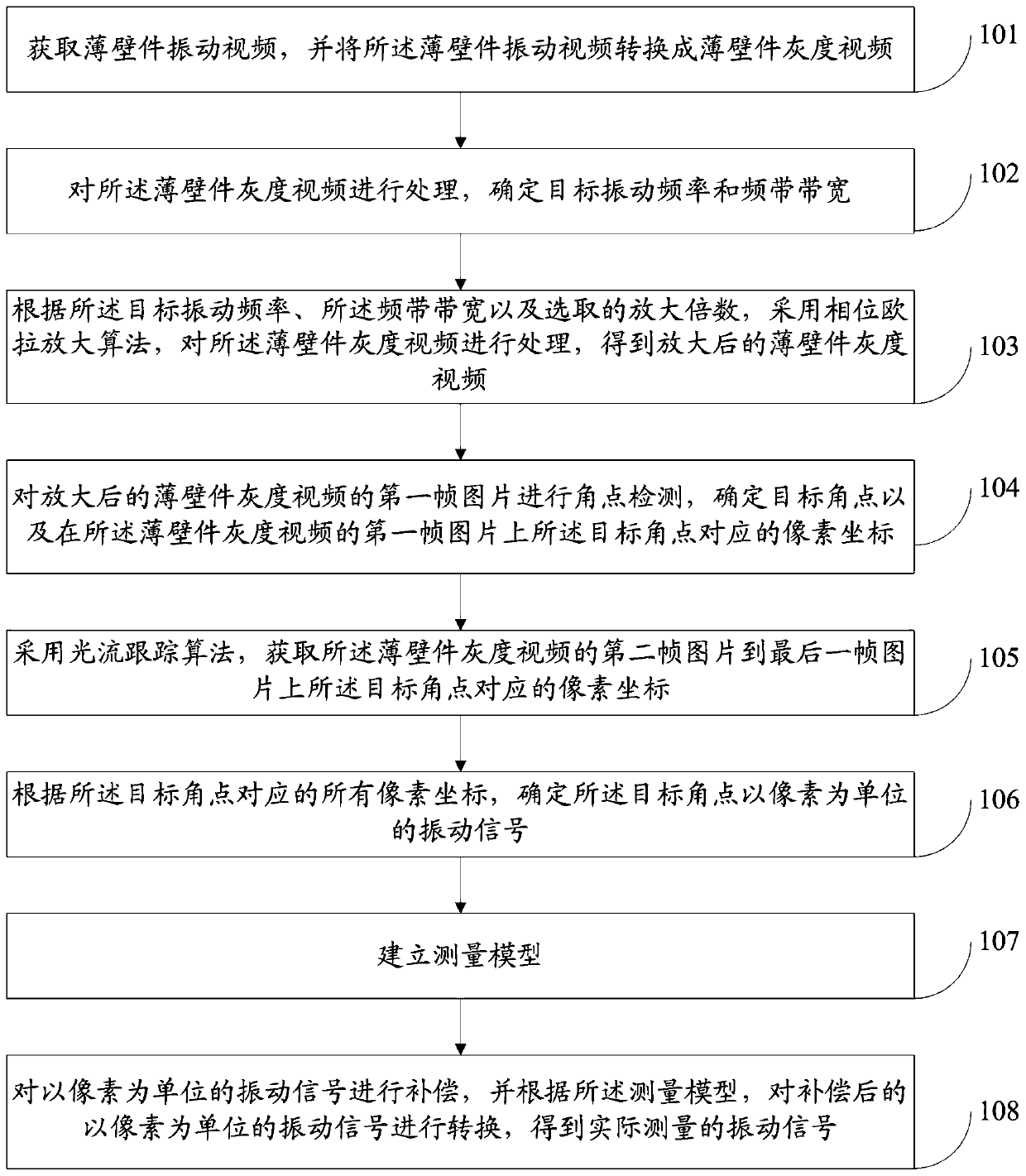

[0060] Such as figure 1 As shown, the method for measuring the micro-vibration of thin-walled parts based on motion amplification optical flow tracking provided by this embodiment includes the following steps:

[0061] Step 101: Obtain a thin-walled part vibration video, and convert the thin-walled part vibration video into a thin-walled part grayscale video.

[0062] Step 102: Process the gray-scale video of the thin-walled part to determine the target vibration frequency and frequency bandwidth.

[0063] Step 103: According to the target vibration frequency, the frequency band width and the selected magnification factor, the phase Euler amplification algorithm is used to process the gray-scale video of the thin-walled part to obtain the enlarged gray-scale video of the thin-walled part.

[0064] Step 104: Perform corner detection on the first frame picture of the enlarged grayscale video of the thin-walled part, and determine the target corner point and the corner point cor...

Embodiment 2

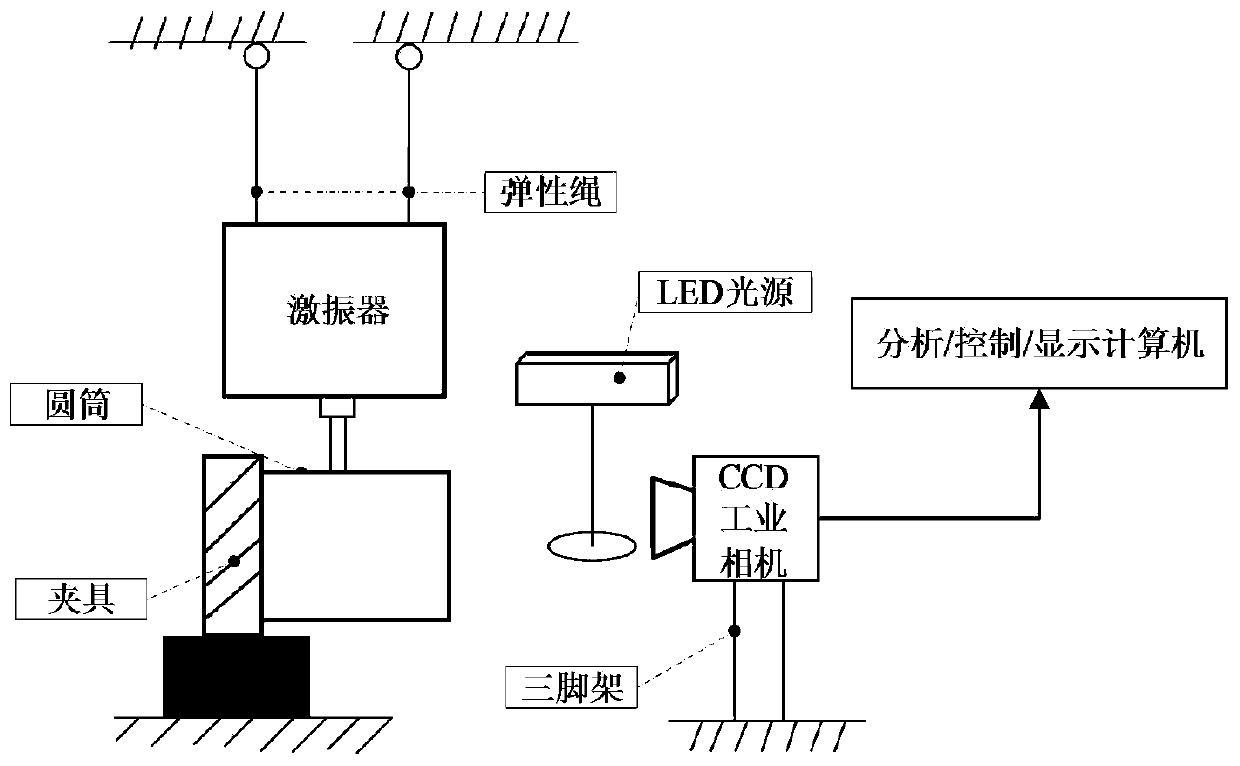

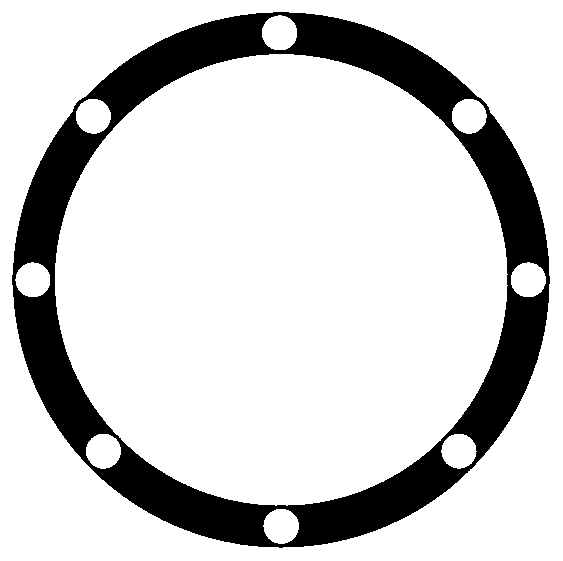

[0082] Such as Figure 2-3 As shown, the thin-walled micro-vibration measurement device based on motion amplification and optical flow tracking of the present invention includes a tripod, a CCD industrial camera, a fixture, a vibrator and its control device, an LED light source, a thin-walled cylinder to be tested, a computer, and an elastic rope . One end of the thin-walled cylinder to be tested is fixed with a fixture, and multiple reflective feature points are arranged at equal intervals at the other end. The vibrator is suspended directly above the thin-walled cylinder to be tested with an elastic rope, and connected to the thin-walled cylinder to be tested through a rod. The CCD industrial camera is fixed horizontally in front of the end face of the thin-walled cylinder to be measured through a tripod, the lens is facing the end face, and the CCD industrial camera is connected to the control device through a data cable. The LED light source is set in front of the end fac...

Embodiment 3

[0101] Such as Figure 4 As shown, this embodiment provides a thin-walled micro-vibration measurement system based on motion amplification optical flow tracking, including:

[0102] Thin-wall grayscale video conversion module 100, configured to acquire thin-wall vibration video, and convert the thin-wall vibration video into thin-wall grayscale video;

[0103] The target vibration frequency and frequency band width determination module 200 is used to process the gray-scale video of the thin-walled part to determine the target vibration frequency and frequency band width;

[0104]The thin-walled part gray-scale video amplification module 300 is used to process the gray-scale video of the thin-walled part by using the phase Euler amplification algorithm according to the target vibration frequency, the frequency band width and the selected magnification factor to obtain the enlarged Grayscale video of thin-walled parts after;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com