In-service pulsed eddy current detection device and method of damage of mine hoisting steel wire ropes

A detection device and pulsed eddy current technology, which are used in measurement devices, instruments, material analysis by electromagnetic means, etc., can solve the problems of low detection accuracy, inconvenient installation and disassembly, and difficulty in realizing detection, and achieve high detection accuracy, installation and disassembly. Convenience and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

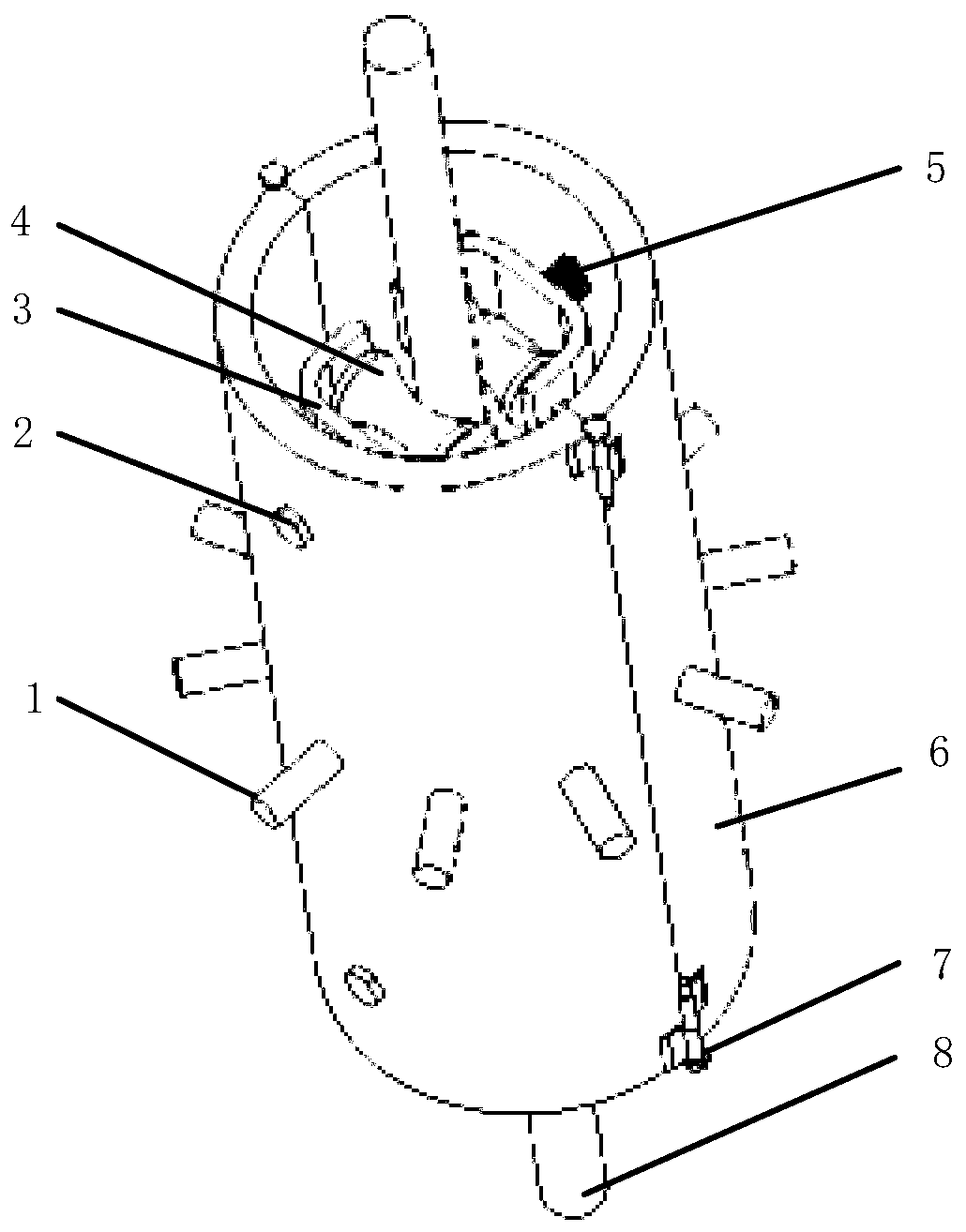

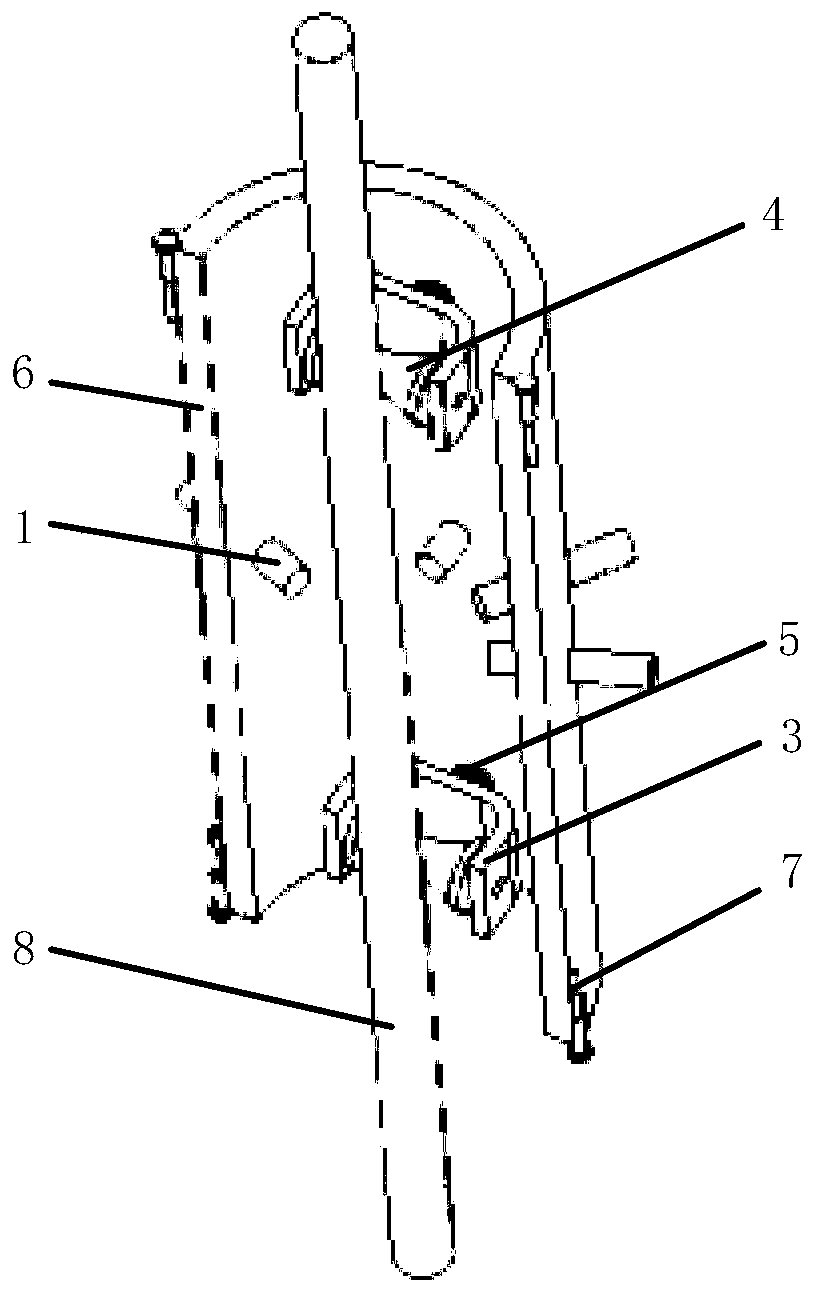

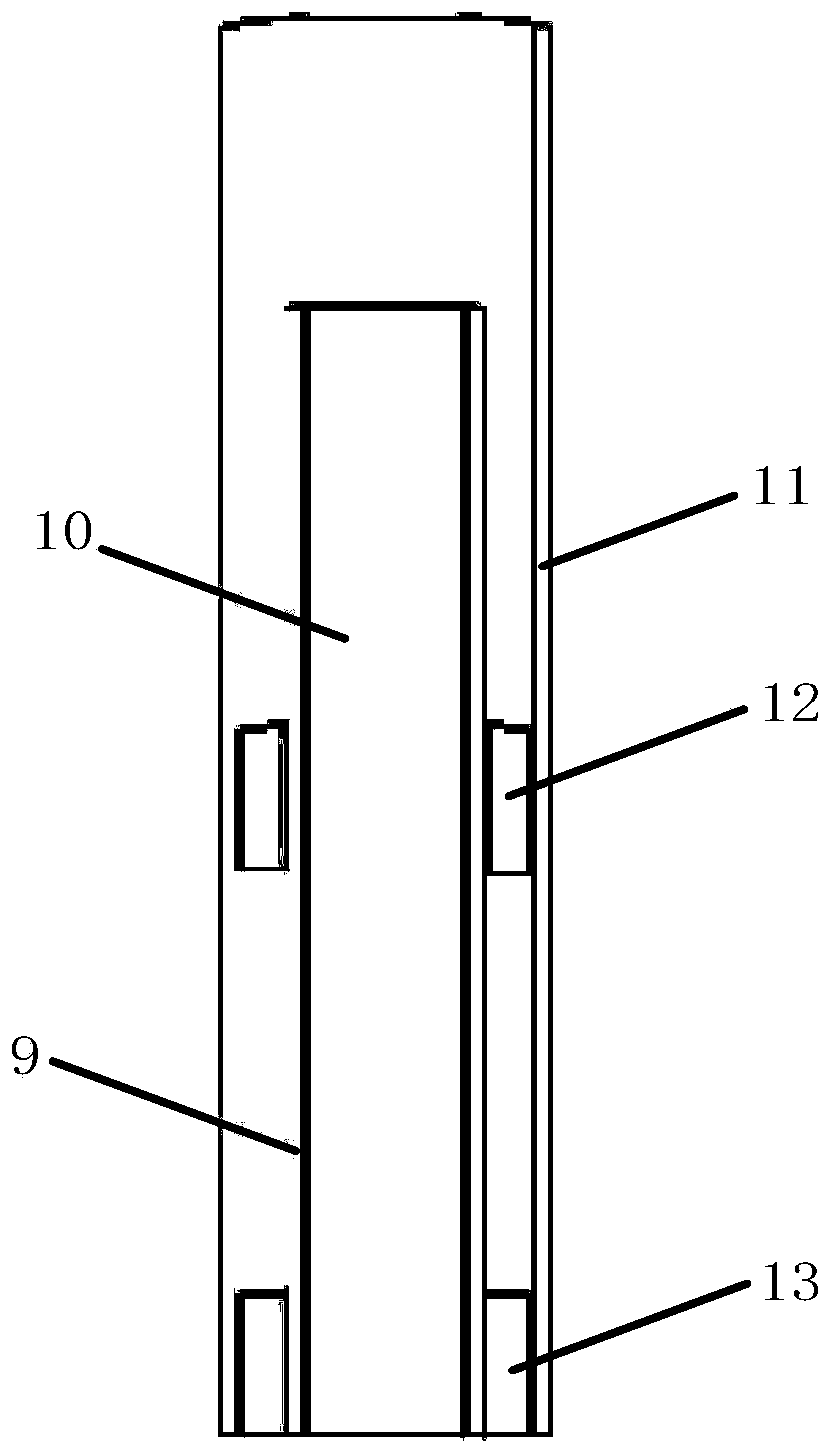

[0051] Example 1: figure 1 , figure 2 Among them, an in-service pulsed eddy current detection device for damage to a mining hoisting wire rope includes a probe sensor 1, a nut 2, a roller bracket 3, a spring 5 of the roller 4, a pin 7 of the side plate of the semicircular tube 6, and the detected wire rope 8 . The roller 4 is fixed on the roller bracket 3 and slides with the movement of the wire rope 8, and the spring 5 is fixed between the roller bracket 3 and the side plate 6 of the semicircular tube, and is used to adjust the diameter of the wire rope 8 clamped by the roller 4 accordingly. The roller brackets 3 are symmetrically distributed, installed at both ends of the detachable semi-circular tube side plate 6, and limited by the nut 2, the pin 7 is used to connect the two detachable semi-circular tube side plates 6, and the probe sensor 1 forms a circumference The array is fixed on the side plate 6 of the semi-circular tube, between the two roller brackets 3 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com