A duplex continuous energy-saving high-gradient magnetic separator for mineral processing

A high-gradient magnetic separator, duplex continuous technology, applied in the direction of high-gradient magnetic separation, high-gradient magnetic separator, magnetic separation, etc., can solve the problem of high power consumption, low efficiency of magnetic Machine complexity and manufacturing costs and other issues, to achieve the effect of simplifying the complex structure, improving the efficiency of magnetic separation, and solving the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

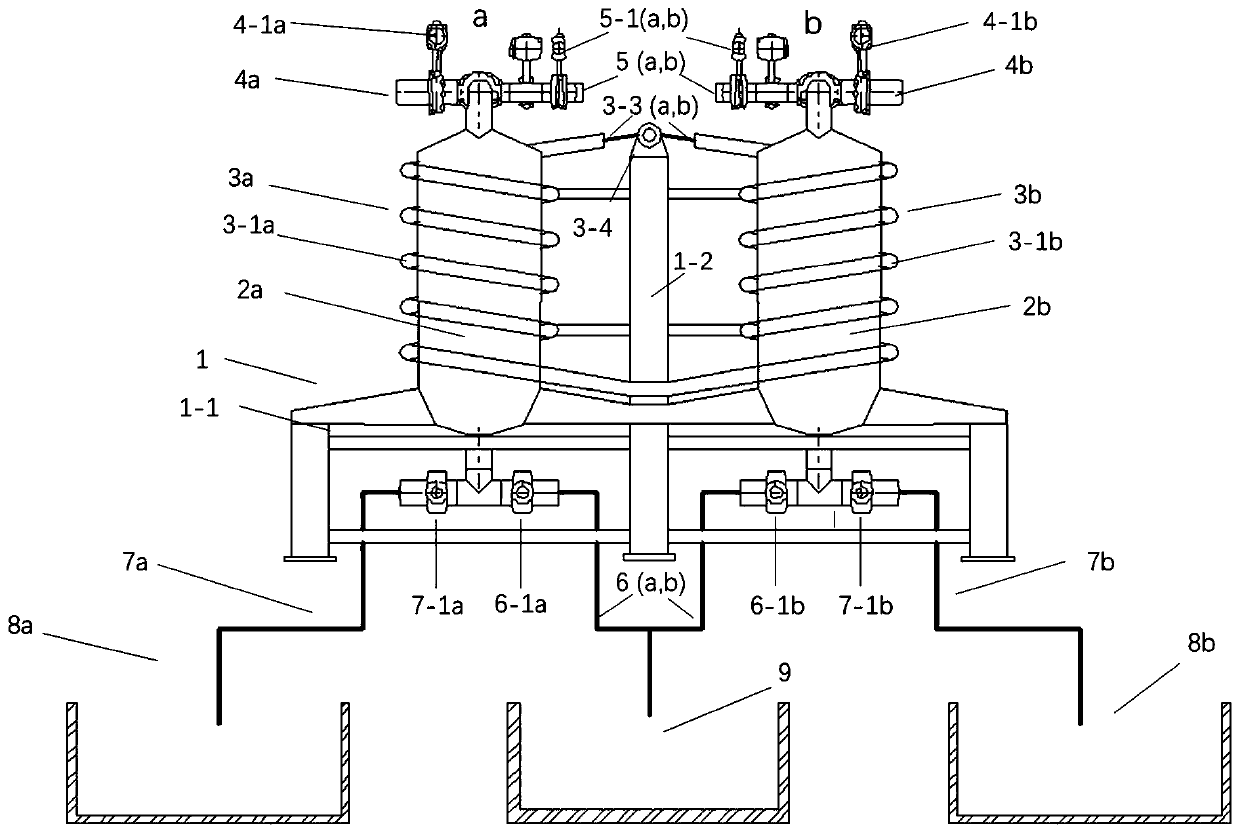

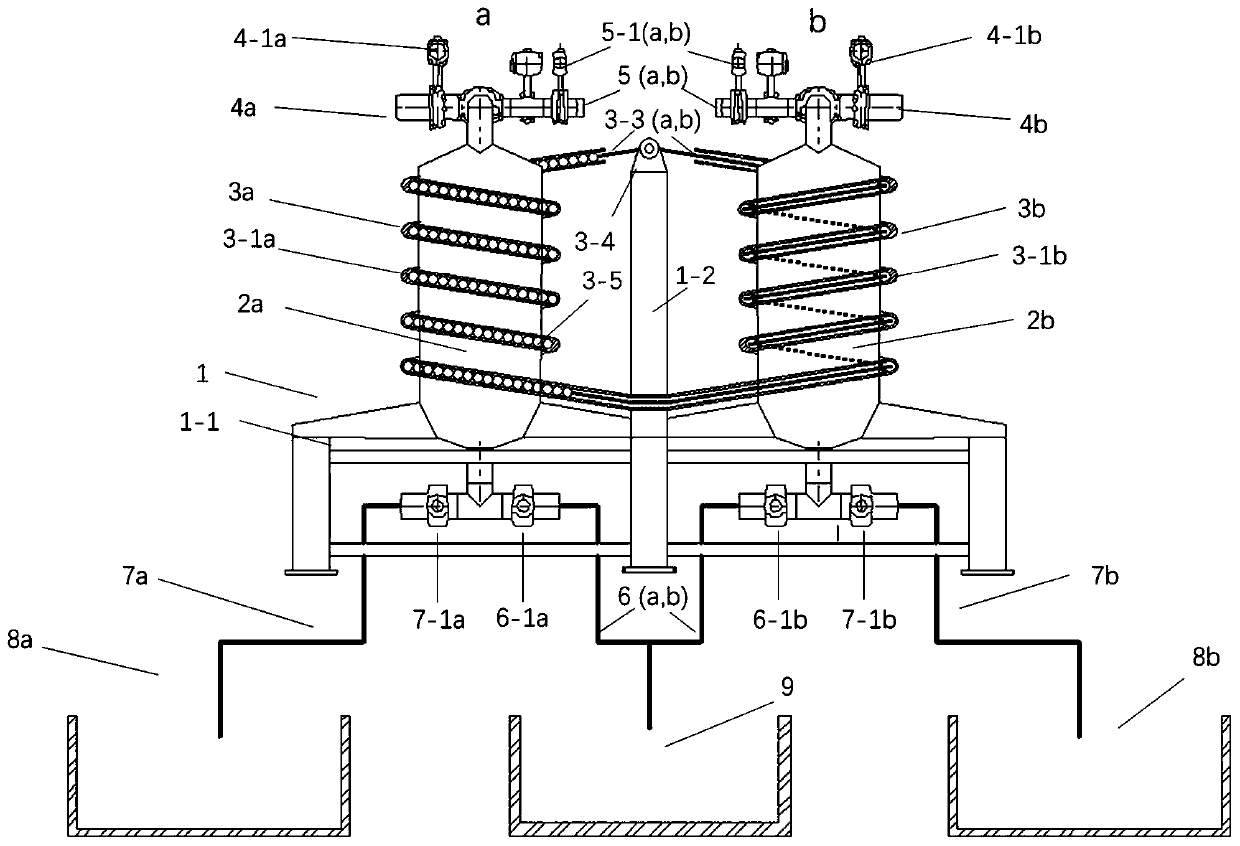

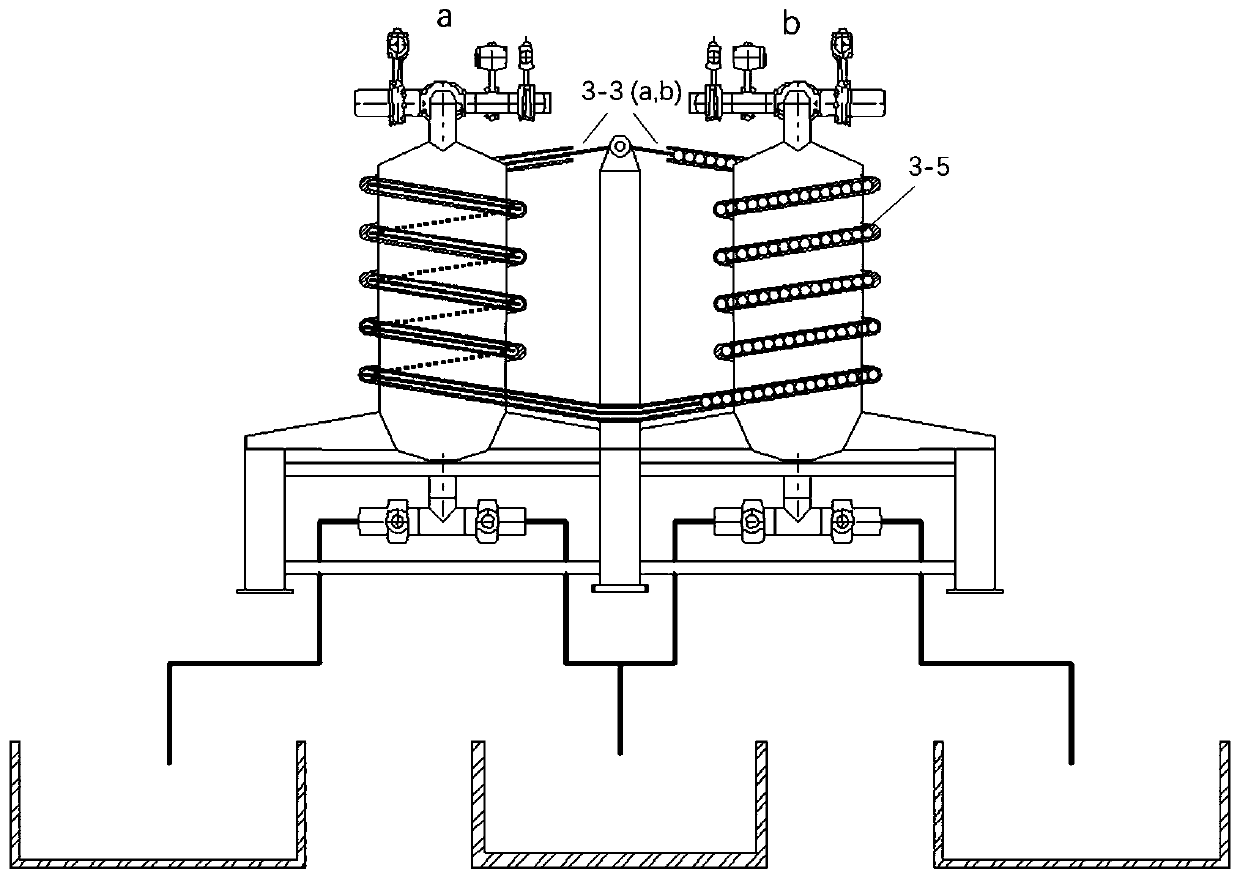

[0031] Refer to attached figure 1 , a dual-link continuous energy-saving high-gradient magnetic separator for mineral processing, has a frame 1, the frame 1 includes a lower base 1-1 and an upper support frame 1-2, and the upper support frame 1-2 is installed on the base 1-1 In the middle part, the above supporting frame 1-2 is symmetrically arranged with two sets of magnetic separation devices a and b, each set of magnetic separation devices includes a magnetic separation part, a magnetic system, a pipeline system and a collection part.

[0032]The magnetic separation parts 2a and 2b are installed symmetrically on the lower base 1-1 with the upper support frame 1-2 as the central axis, and the magnetic systems 3a and 3b are fixed and correspondingly installed on the outside of the magnetic separation parts 2a and 2b through the upper support frame 1-2 The magnetic separation part 2a, 2b is an internal hollow cavity structure, which has a magnetic separation cavity wall 2-1a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com