A magnetic fluid energy-saving high-gradient magnetic separator for mineral processing

A high-gradient magnetic separator, magnetic fluid technology, applied in high-gradient magnetic separation, high-gradient magnetic separator, cleaning method using liquid, etc., can solve the problem of high power consumption, improve the complexity and Manufacturing costs and other issues, to achieve the effect of solving large energy consumption and simplifying complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

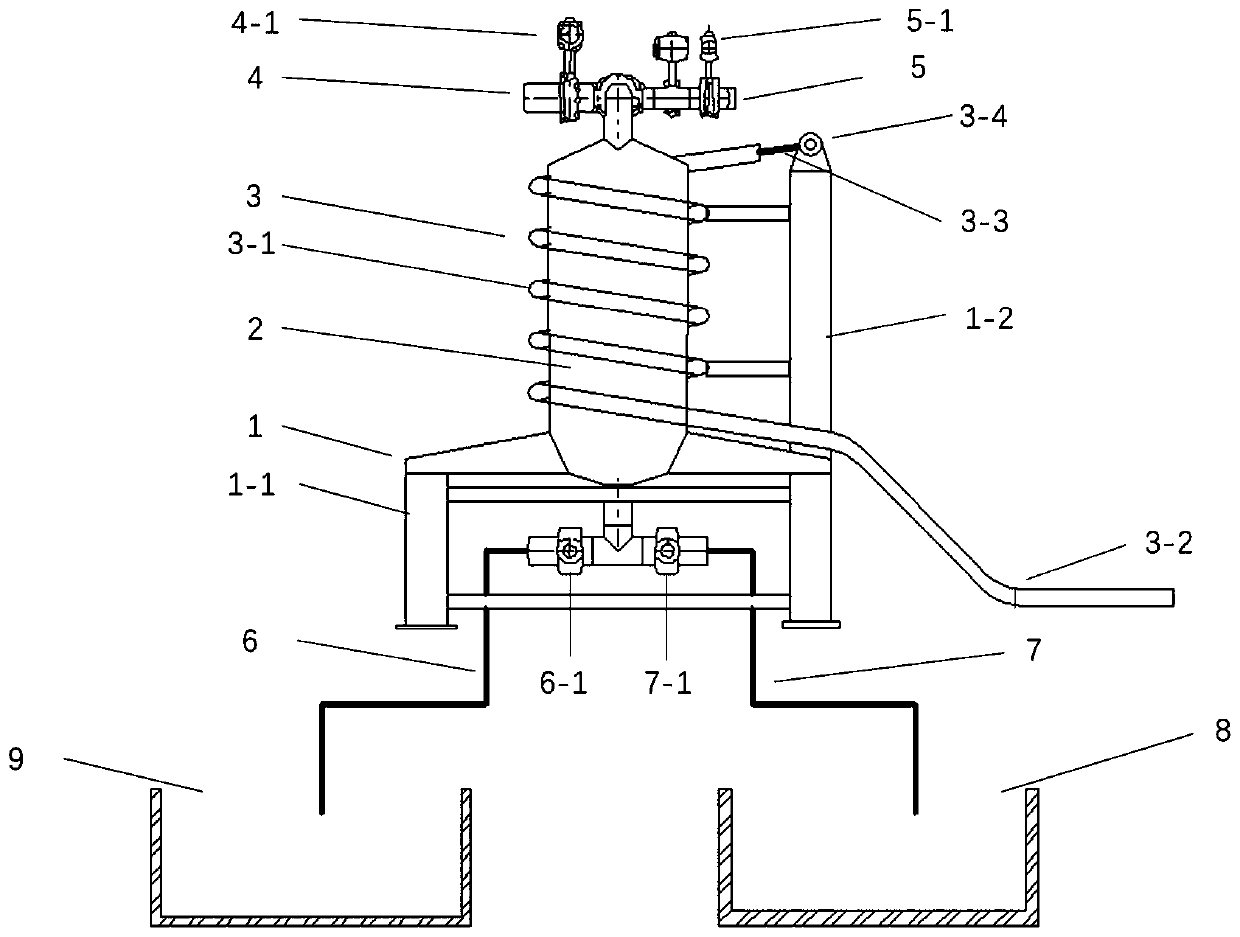

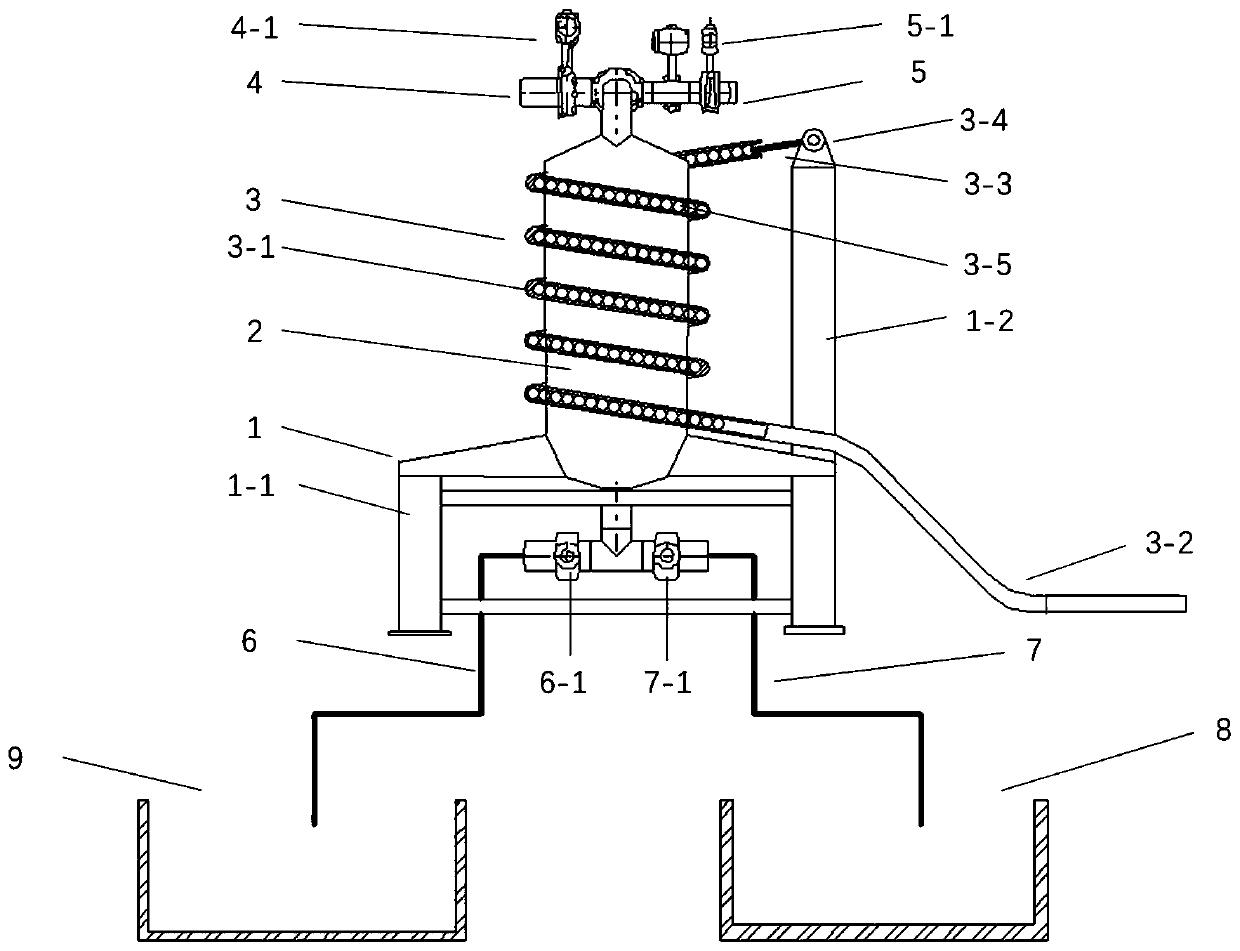

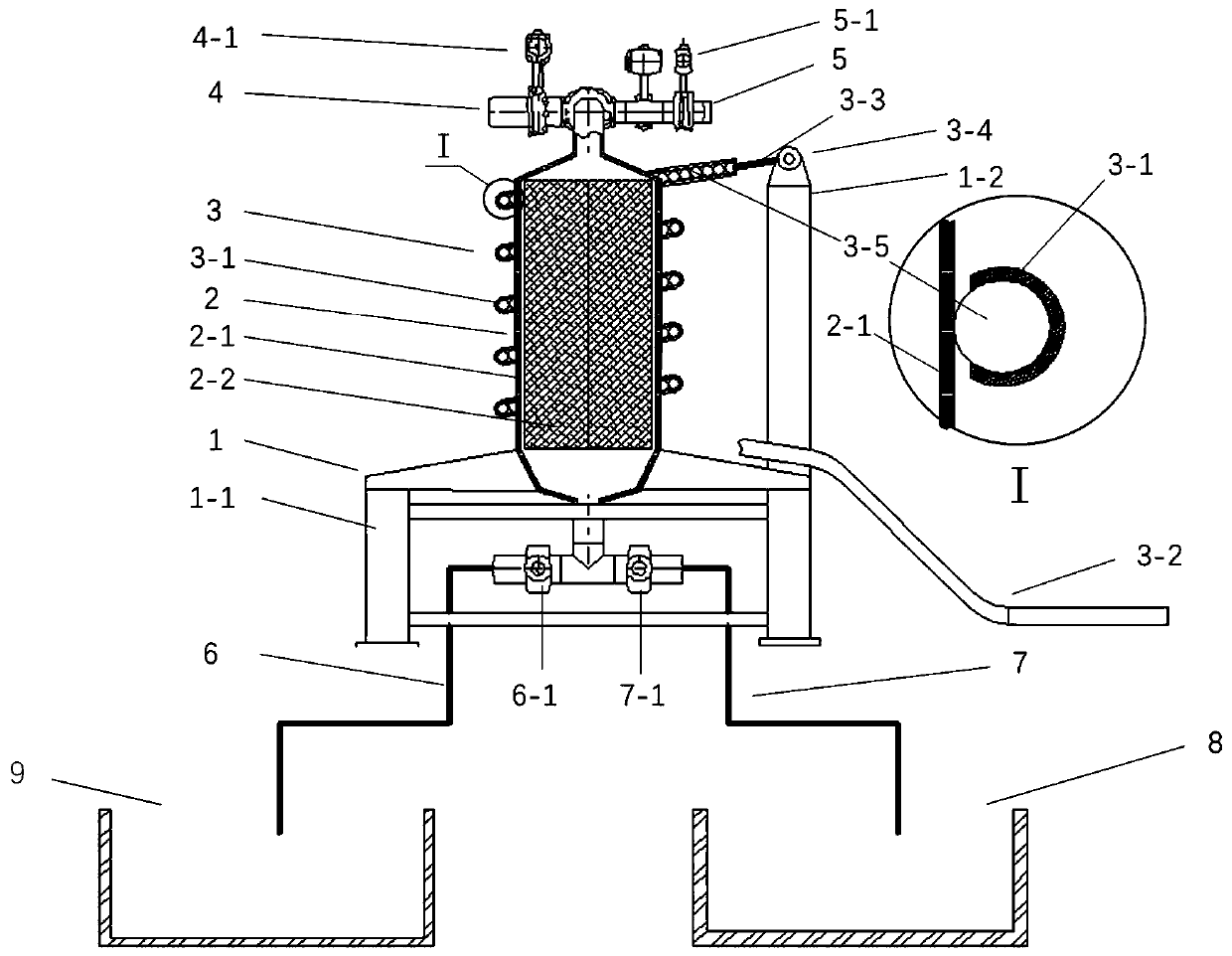

[0036] Refer to attached figure 1 A low-power and energy-saving high-gradient magnetic separator for mineral processing, including a frame 1, a magnetic separation part 2, a magnetic system 3, a pipeline system, and a collection part; the frame 1 includes a lower base 1-1 and an upper support frame 1 -2.

[0037] The magnetic separation part 2 is installed on the lower base 1-1, and the magnetic system 3 is fixedly installed on the outside of the magnetic separation part 2 through the upper support frame 1-2; the magnetic separation part 2 is a cavity structure with a hollow inside and has a magnetic separation cavity 2-1, which is made of magnetically conductive or paramagnetic materials, such as magnetically conductive stainless steel; a magnetic separation medium 2-2 is arranged in the magnetic separation chamber of the magnetic separation part 2, and the magnetic separation medium 2-2 is teeth filled at intervals Plate media, spaced-packed round bar media, tightly-packed ...

Embodiment 2

[0051] Another low-power and energy-saving high-gradient magnetic separator for ore dressing using ferrofluid, see attached Figure 7 On the basis of embodiment 1, the collection tray 3-2, collection tank 3-2-1, traction rope 3-3, lifting device 3-4 and permanent magnet 3-5 in the original embodiment 1 are replaced by magnetic Fluid pipeline 3-6, circulating pump 3-7, discharge valve 3-8, magnetic fluid reservoir 3-9 and polarized coil 3-10 (optional), the spiral pipeline 3 in the original embodiment 1 -1 is changed to a closed pipe, the cross-section of which is preferably rectangular, made of inorganic non-metallic materials, such as glass and other materials. The magnetic fluid pipeline 3-6 is connected with the spiral pipeline 3-1, and the circulating pump 3-7, the discharge valve 3-8, and the polarizing coil 3-10 (optional) are all installed on the magnetic fluid pipeline 3-6 , and the magnetic fluid reservoir 3-9 communicates with the magnetic fluid pipeline 3-6 at the ...

Embodiment 3

[0064] See attached Figure 8 , a kind of enhanced low power consumption energy-saving type high gradient magnetic separator, it has increased a helical pipeline 3-1 and its matching collection plate 3-2, traction rope 3-3, The hoisting device 3-4 and the permanent magnet 3-5 adopt a double-layer spiral pipeline, the two spiral pipelines have opposite directions of rotation, and the permanent magnets 3-5 in the two spiral pipelines 3-1 have opposite polarity sequences at the head and tail. So that the magnetic system 3 can generate magnetic induction lines superimposed in the same direction in the magnetic separation cavity of the magnetic separation part 2, and is used to increase the intensity of the magnetic field formed in the magnetic separation cavity of the magnetic separation part 2, its working principle, control method and implementation Same as in Example 1.

[0065] Simultaneously, also can try on the basis of embodiment 2 to increase a helical pipeline 3-1 and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com