Loose core sheet riveting device

A riveting device and chip technology, which is applied in the field of riveting, can solve problems affecting the degree of freedom of chip extraction, user experience, and product appearance, so as to avoid being squeezed and deformed, with good freedom of movement and good product appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with specific embodiment, this case is described in further detail.

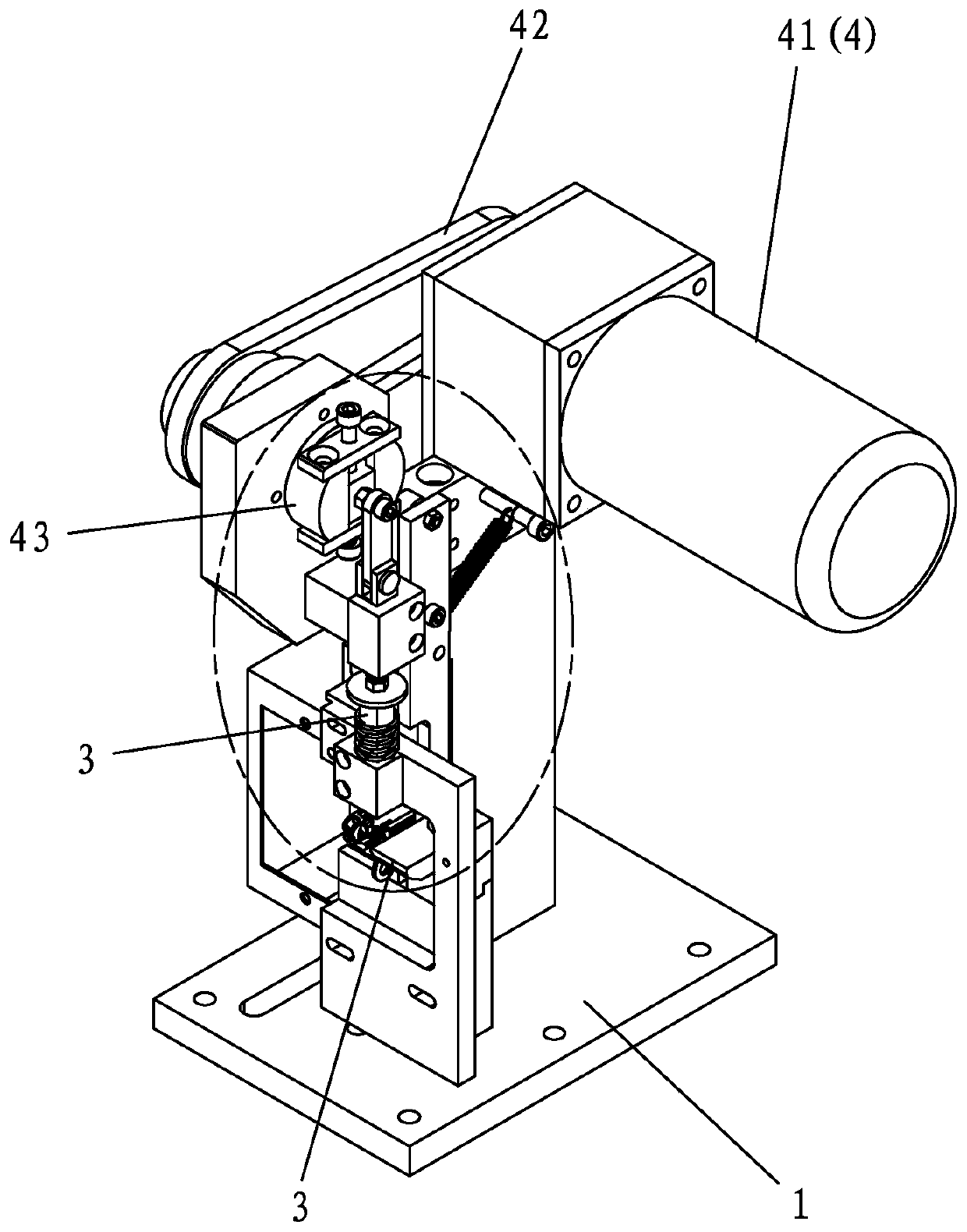

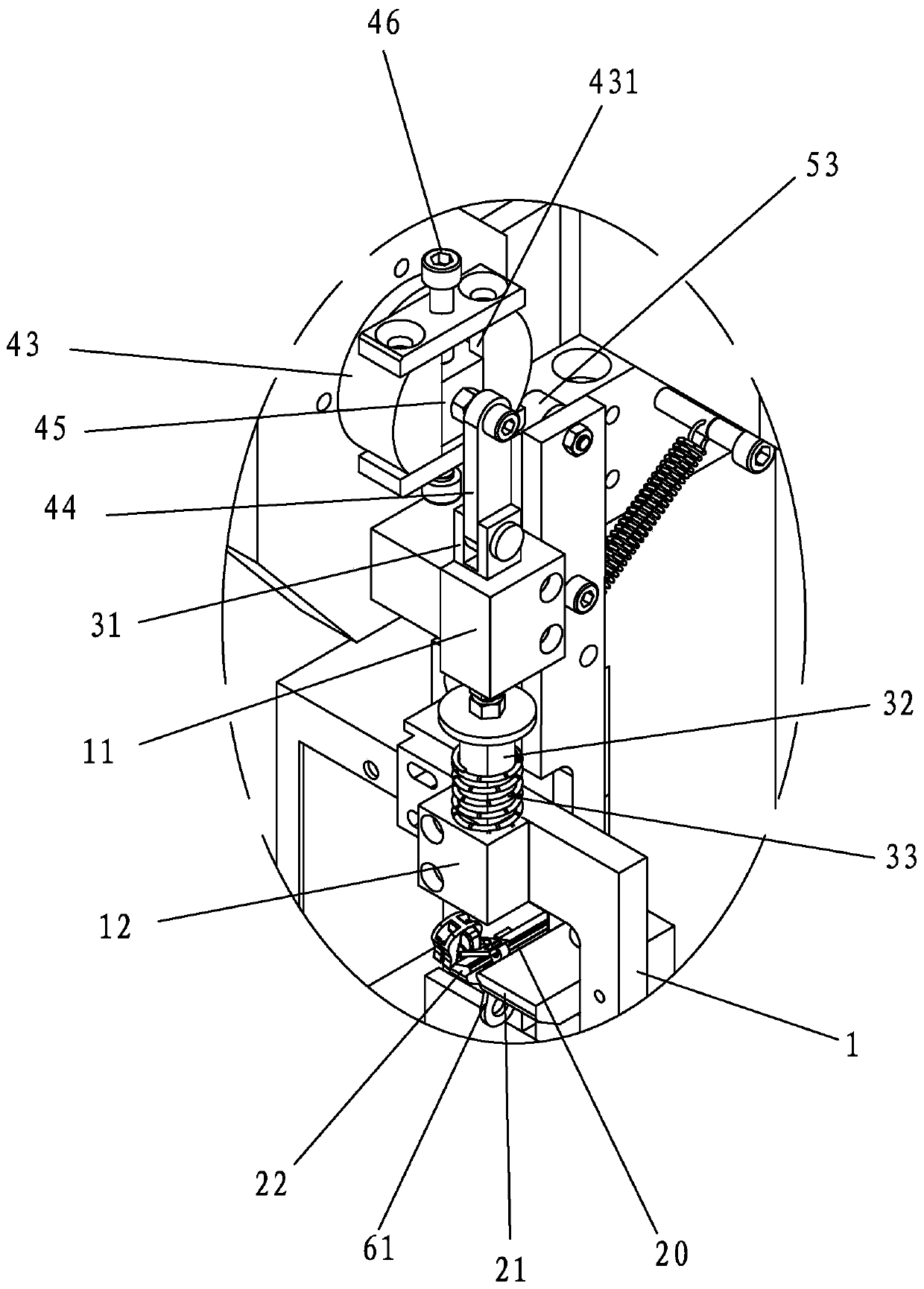

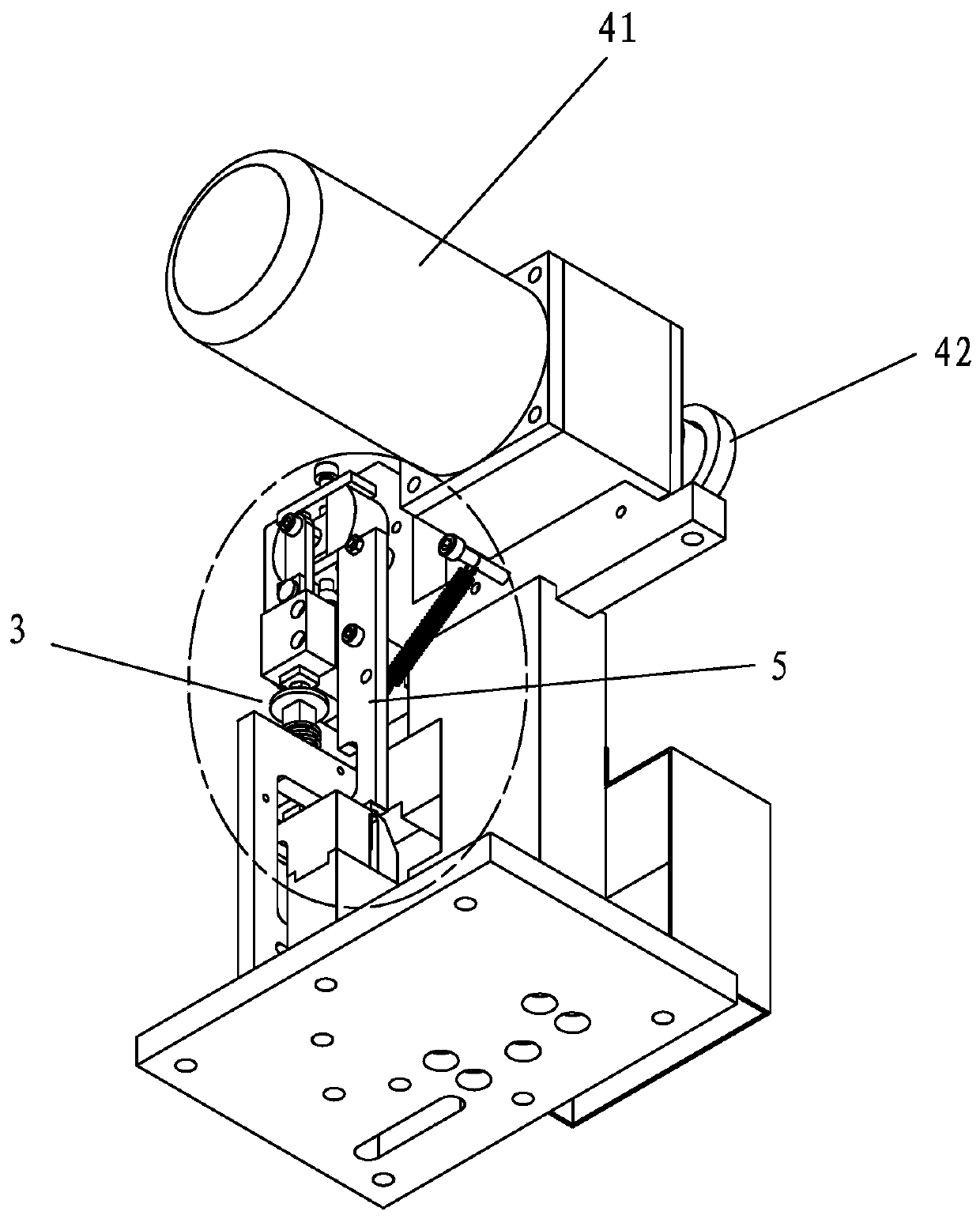

[0039] This case involves a chip riveting device, such as Figure 1-8 As shown, it mainly includes a support assembly 2 , a riveting assembly 3 and a riveting drive assembly 4 ;

[0040] The support assembly 2 is used to place and support the product to be riveted to remove the chip, and it has a positioning position 20 for positioning the chip to be removed. The set piece position 20 has a reference direction, which is the axial direction corresponding to the opening to be riveted after the chip is pulled out and positioned on the set piece position 20 . Specifically, the pulling chip 61 has two oppositely arranged riveting portions 611 to be riveted, and an opening 610 to be riveted is arranged between the two riveting portions 611, and the closing direction of the riveting opening 610 is the opening direction (see Figure 7 mid-horizontal direction), the axial direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com