Unloading device of combine harvester

A technology of combine harvester and bagging device, which is applied in the direction of digging harvester, harvester, agricultural machinery and implements, etc., and can solve the problem of unloading undisclosed potatoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

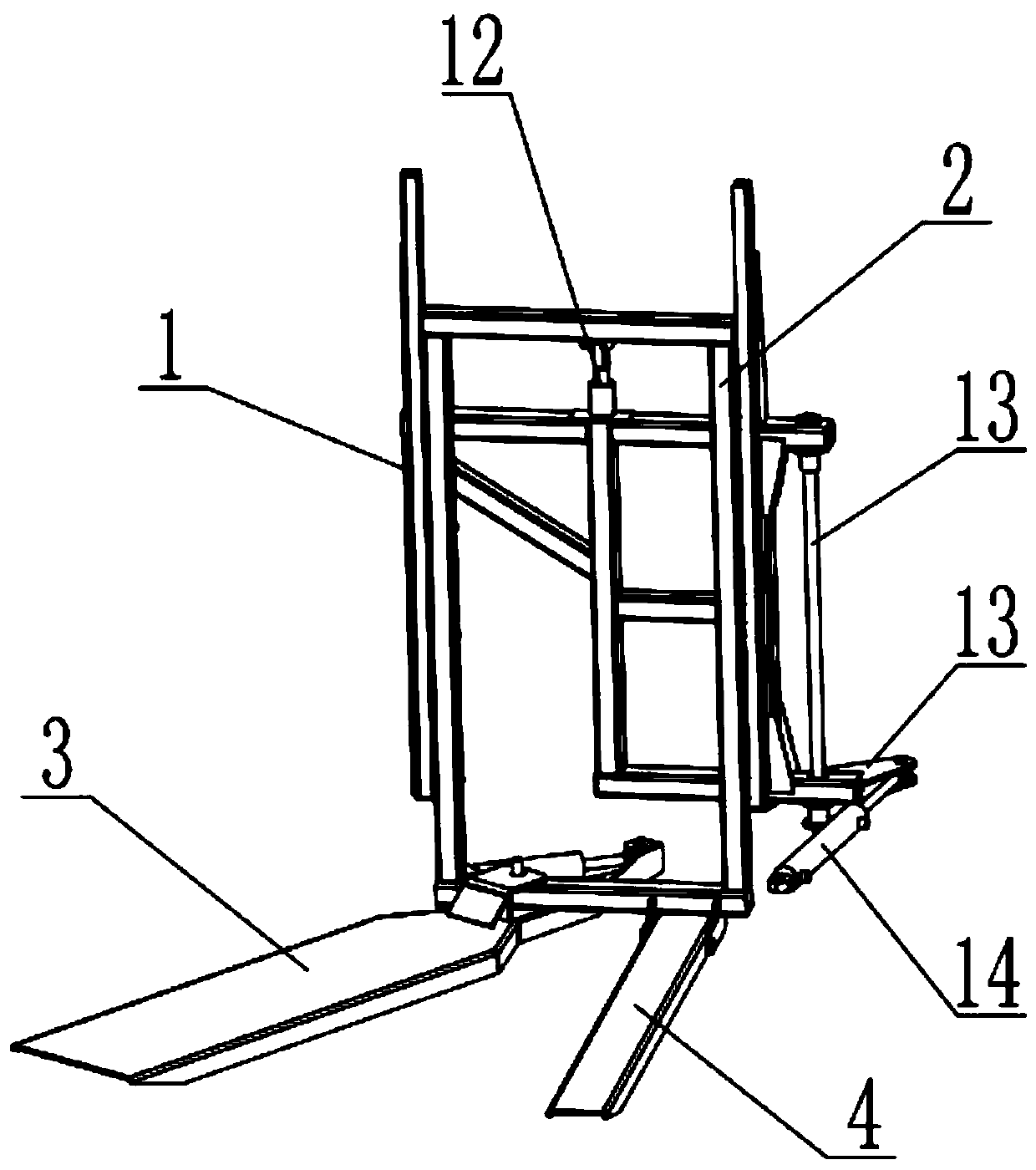

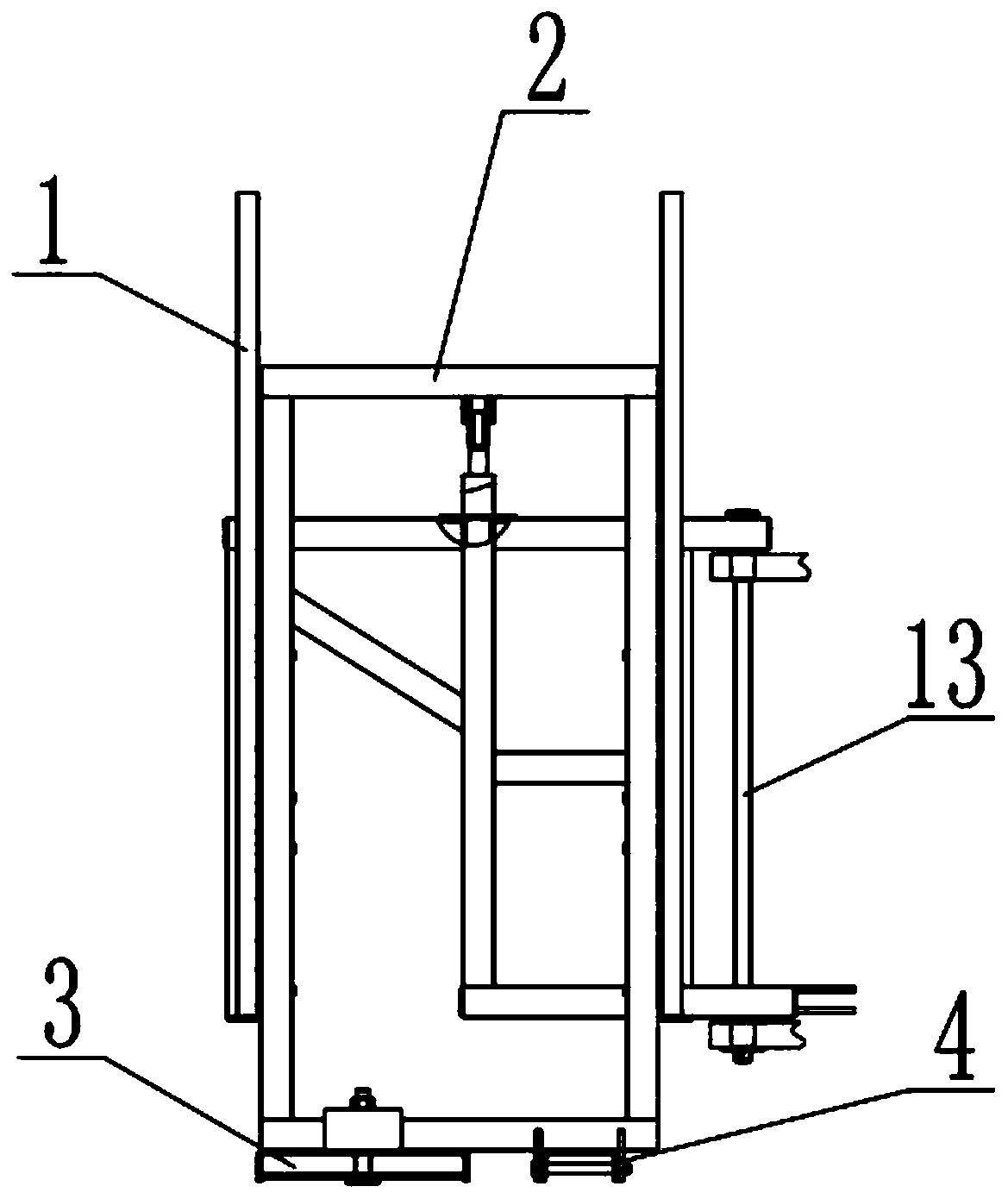

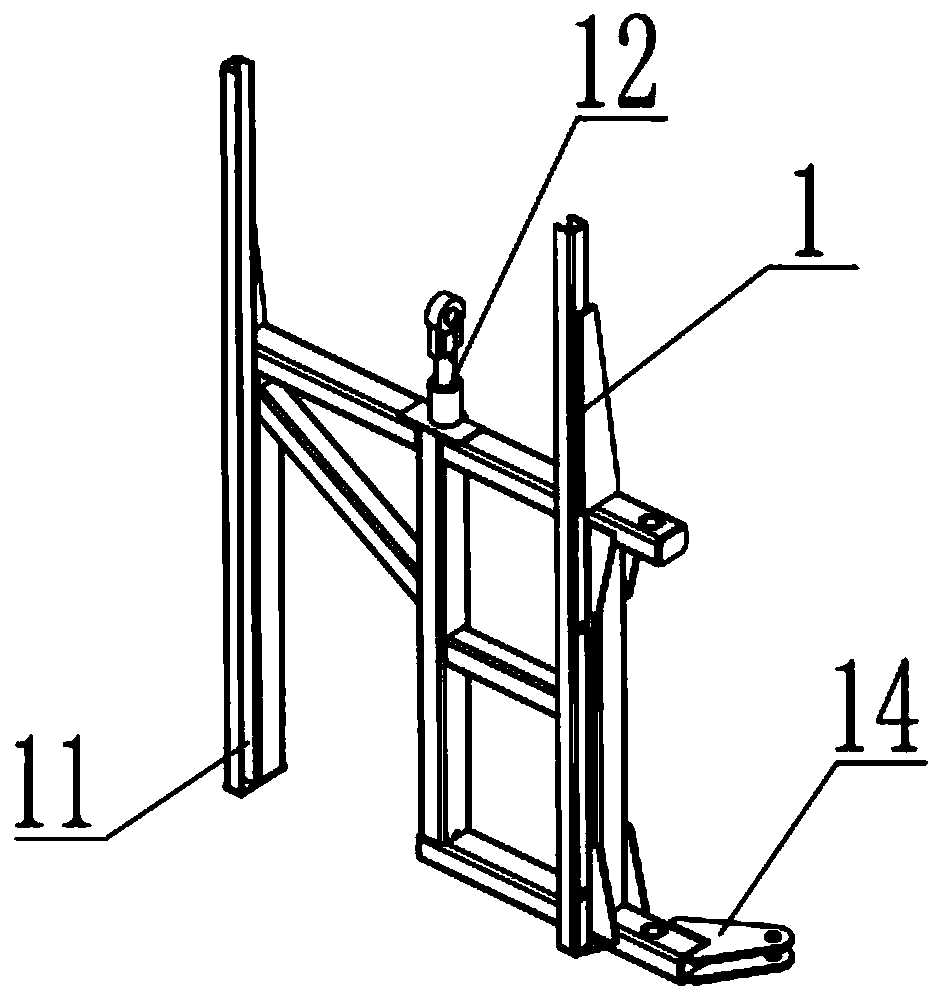

[0034] Such as Figure 1 to Figure 5 As shown, in this embodiment, a combine harvester unpacking device is provided, including a rotating support 1, a lifting support 2 and a supporting device. One side of the rotating support 1 is rotatably connected to the tail of the combine harvester 5, the lifting support 2 is arranged on the rotating support 1, and is vertically slidably connected with the rotating support, and the supporting device is arranged on the lifting support 2.

[0035] The rotating bracket 1 and the lifting bracket 2 can slide relative to each other through the slide rail 11 and the slider 21 , and the lifting bracket 2 is driven by the lifting cylinder 12 . One side of the rotating bracket 1 is provided with a rotating connection part 13, which may include a rotating shaft, or is provided with a shaft hole, and the rotating connecting part 13 is connected with the combine harvester 5. The rotary support 1 is also provided with a drive arm 14 on the side where...

Embodiment 2

[0042] A combine harvester using the above-mentioned unpacking device for a combine harvester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com