Intelligent rack machining device

A processing device and rack technology, which is applied to gear tooth manufacturing devices, metal processing equipment, gear tooth manufacturing tools, etc., can solve the problems of machining accuracy errors, low machining accuracy, and low production efficiency, and achieves improved machining accuracy. The effect of improving processing efficiency, improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

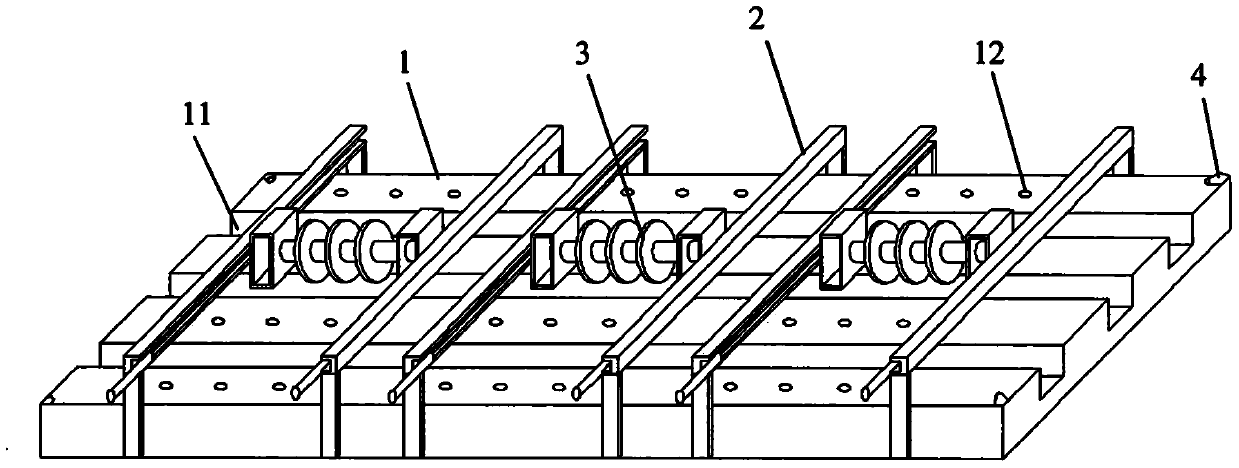

[0046] See attached figure 1 to attach image 3 , the embodiment of the present invention discloses an intelligent rack processing device, including: a pedestal 1, a support frame 2 and a hobbing assembly 3;

[0047] There are a plurality of processing grooves 11 parallel to the surface of the pedestal 1;

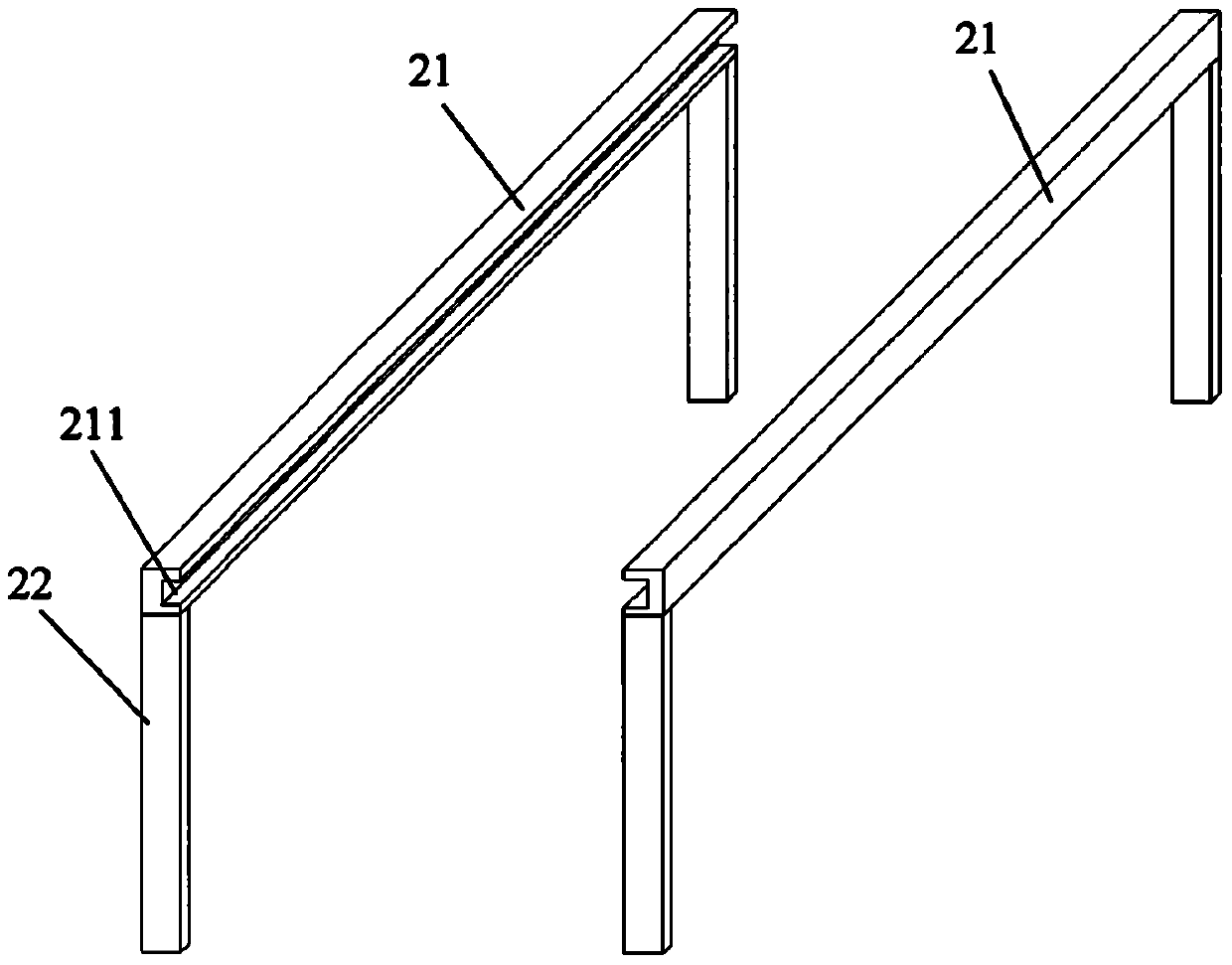

[0048] There are multiple support frames 2, and the support frame 2 includes a cross bar 21 and a support bar 22; the two cross bars 21 are arranged in parallel above the pedestal 1, and are perpendicular to the processing tank 11, and the opposite surfaces of the two cross bars 21 are opened There is a chute 211; the number of support rods 22 is four, and the two ends of the support rods 22 are respectively fixedly connected to the end of the cross bar 21 and the side wall of the pedestal;

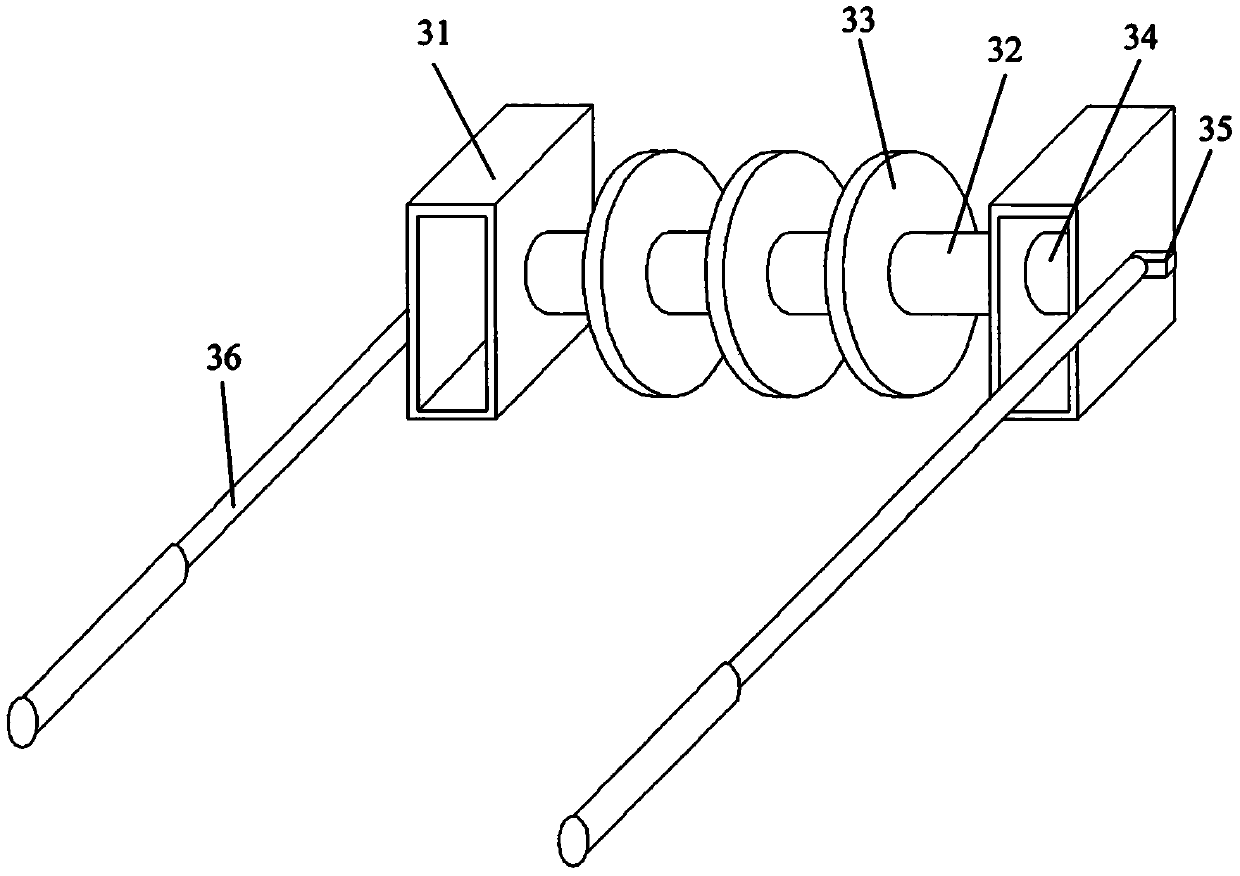

[0049] The gear hobbing assembly includes a box-shaped plate 31, a rotating shaft 32, a cutter wheel 33, a motor 34, a slider 35 and a hydraulic rod 36; two box-shaped plates 31 are ...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that the number of processing tanks 11 and support frames 2 is four. Other structures and working principles are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com