Die and automatic production line using die

A technology for automated production lines and molds, applied in the field of molds and automated production lines, can solve problems such as high cost, low manual operation efficiency, and uneven quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

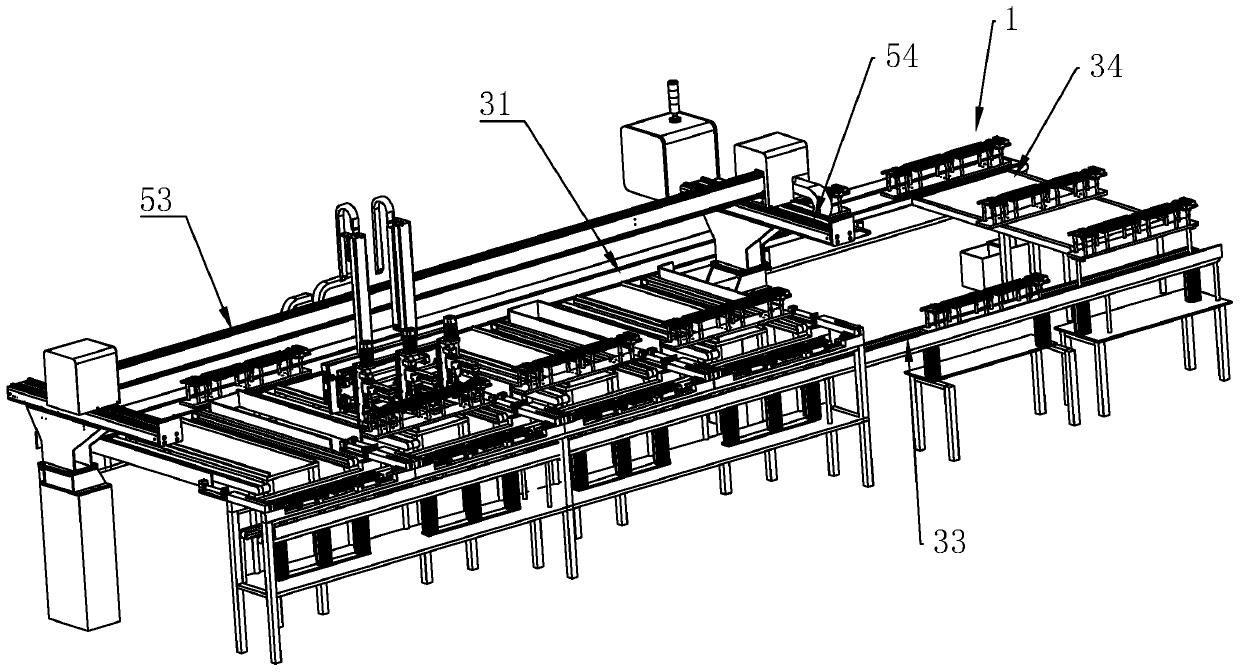

[0027] refer to Figure 1 to Figure 7 A mold of the present invention and an embodiment of an automated production line using the mold will be further described.

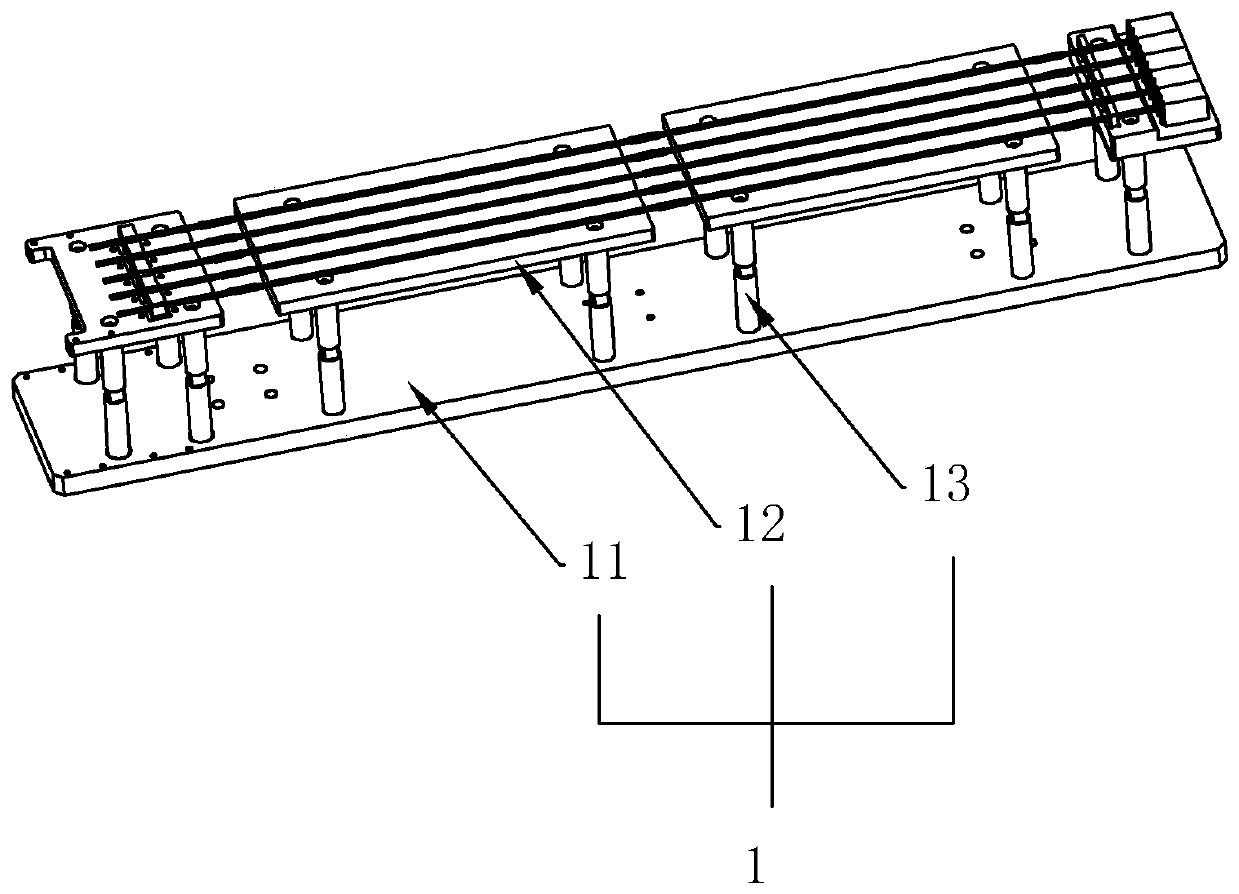

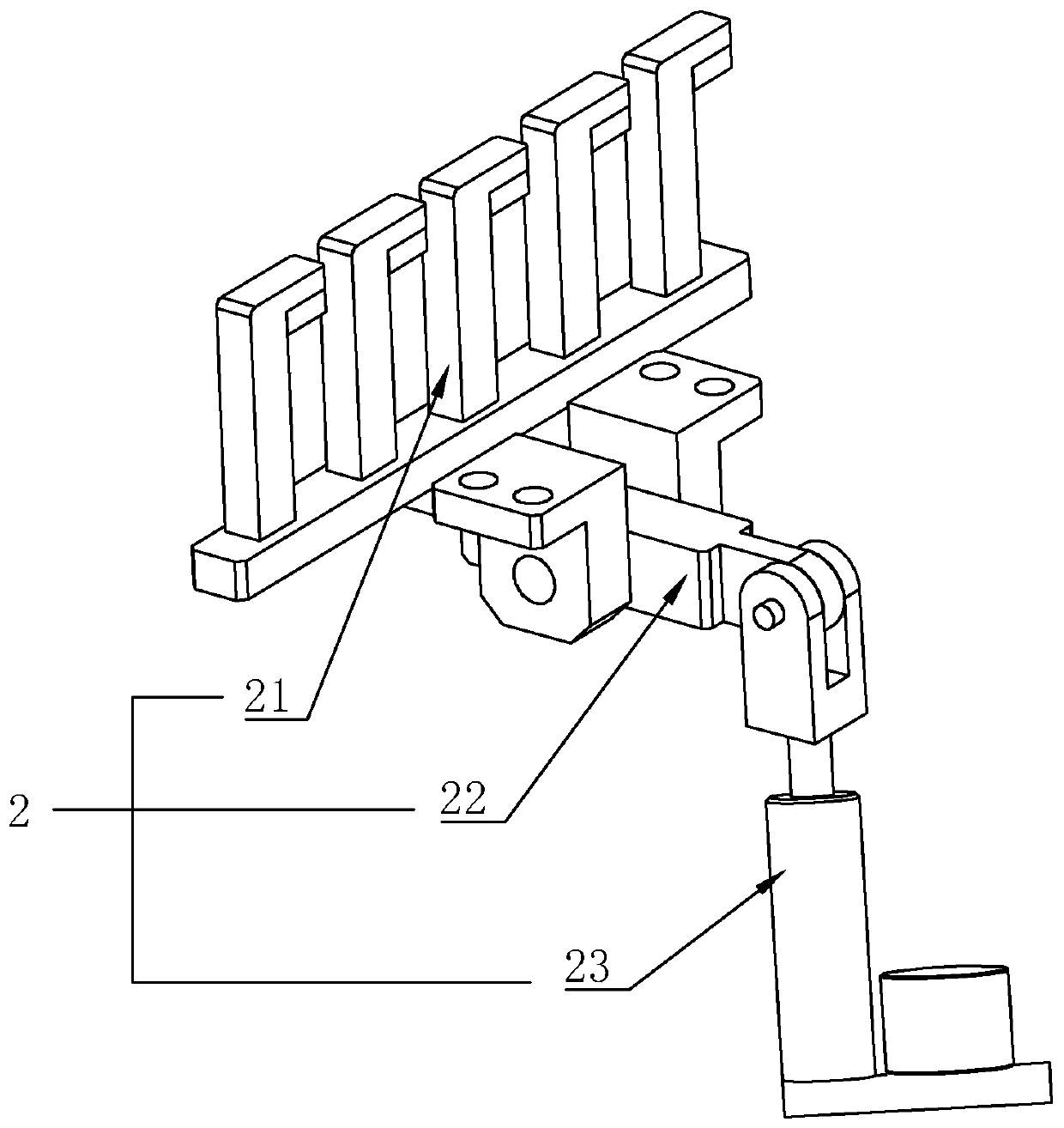

[0028] according to figure 1 As shown, a mold includes a base plate 11, a platen 12 for placing wires, and a balance column 13 for suspending the platen 12 above the base plate 11. Both the base plate 11 and the platen 12 are made of rubber and plastic materials , have high hardness and can be insulated, the deck 12 includes a first deck 12 and a second deck 12, the first deck 12 and the second deck 12 are on the same horizontal plane and arranged at intervals, the first deck 12 and the second deck Clamping mechanisms 2 for fixing wires are arranged on the boards 12 .

[0029] continue figure 1 As shown, the balance column 13 is arranged between the platen 12 and the base plate 11, so that the platen 12 is suspended in the air. The balance column 13 is mainly composed of a first connecting rod, a second connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com