Armrest base for cart

A technology for handrails and trolleys, which is applied to trolleys, trolley accessories, motor vehicles, etc. It can solve the problems of inaccurate positioning of welding parts and low work efficiency, and achieve the effects of improving installation efficiency, simple structure, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

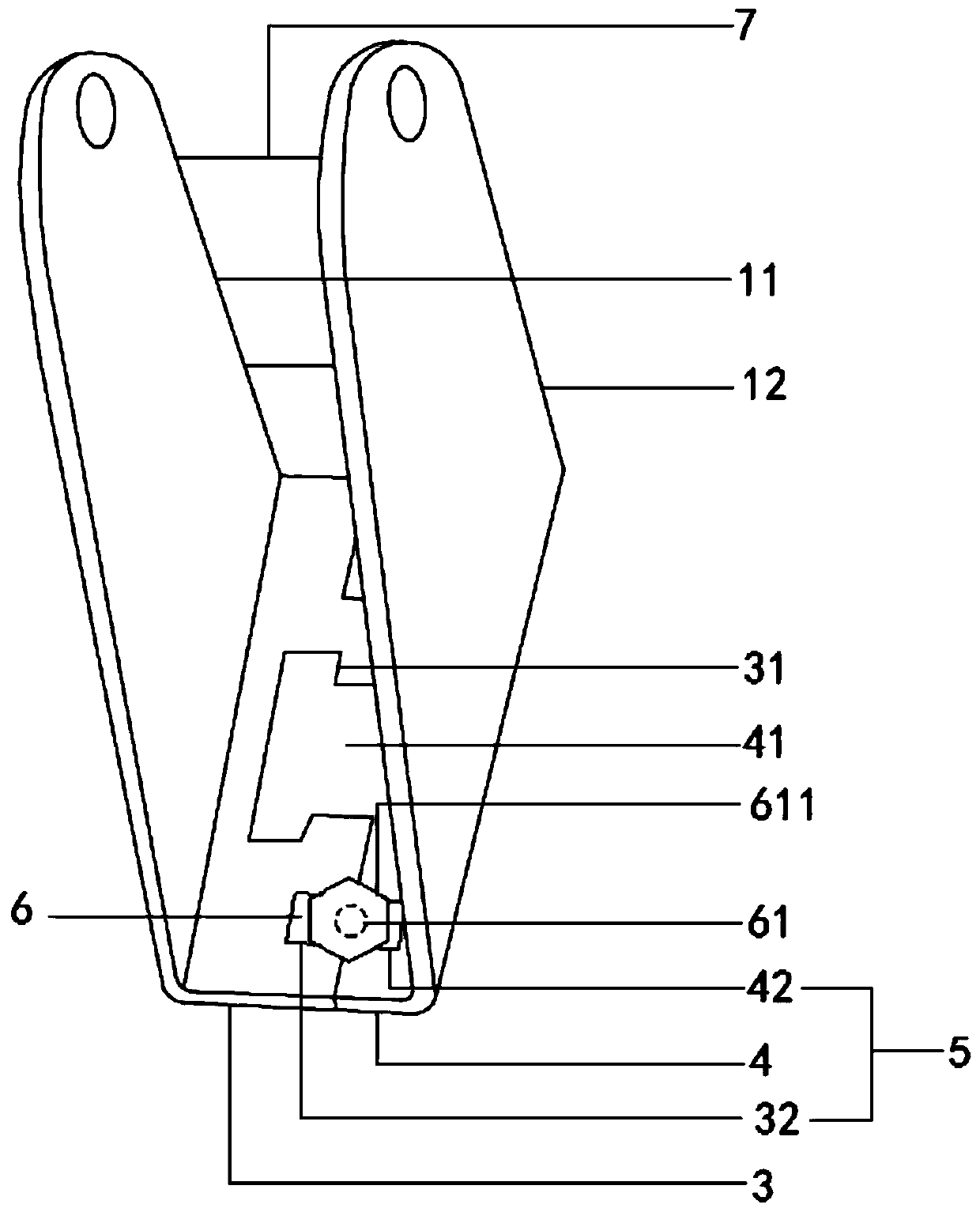

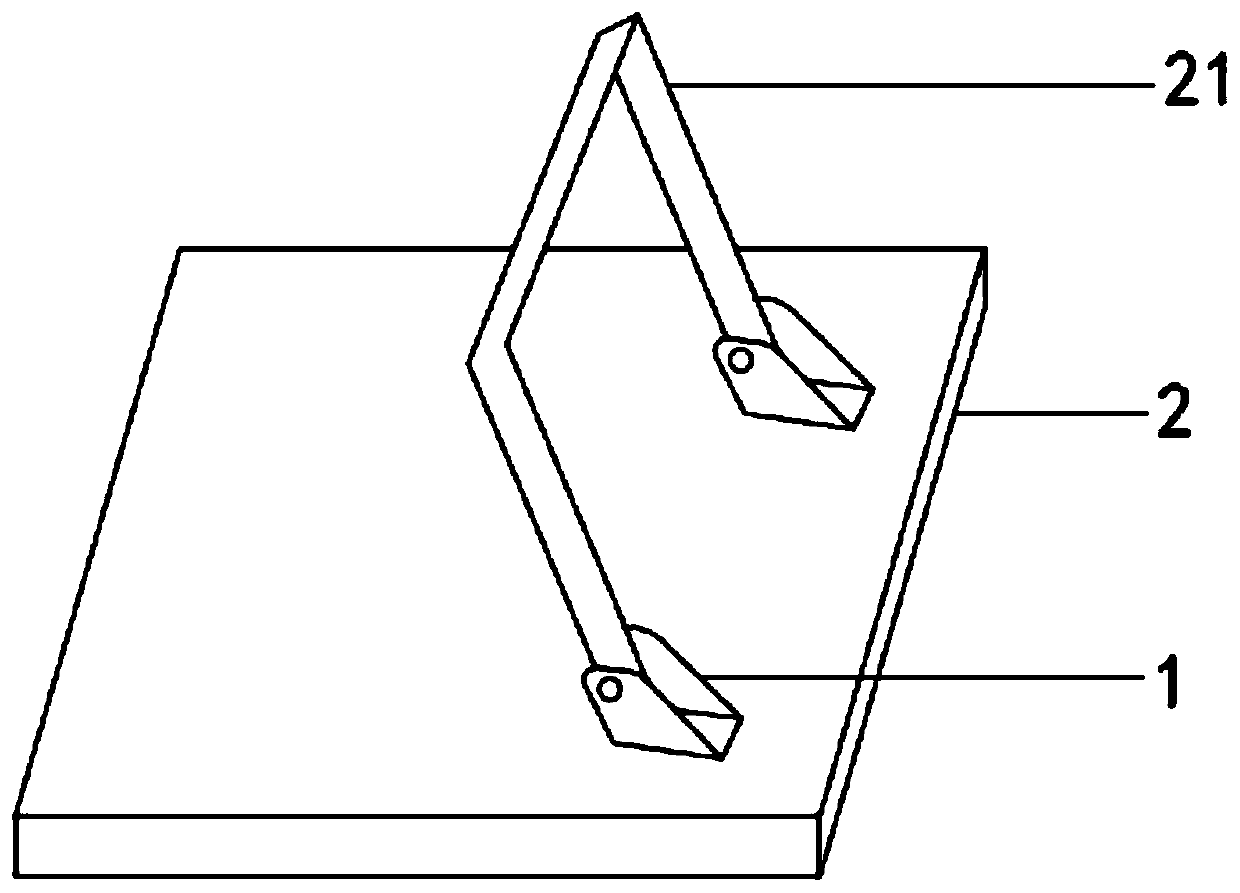

[0030] see figure 1 , the figure shows an armrest base for a cart provided by Embodiment 1 of the present invention, which includes an armrest base member 1, which is fixedly installed on the cart floor 2, and the end of the armrest 21 is rotatably connected to the armrest base member 1. The armrest base component 1 includes a first side plate 11 and a second side plate 12, one end surface of a reinforcement plate 7 is fixedly connected to the first side plate 11, and the other end surface of the reinforcement plate 7 is fixedly connected to the second side plate 12, the first side plate 11 and the second side plate 12 are both L-shaped, the top of the first side plate 11 and the top of the second side plate 12 are pierced with rotating shafts, and the two fixed ends of the armrest 21 are respectively rotatably connected to On the two rotating shafts, the first side plate 11 has a first bent end plate 3, the second side plate 12 has a second bent end plate 4, a notch 31 is pro...

Embodiment 2

[0038] see figure 1 , the figure shows an armrest base for carts provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first The second notch 32 and the third notch 42 are designed as convex-shaped notches, and the convex-shaped notch has a position-limiting effect.

Embodiment 3

[0040] see figure 1 , the figure shows an armrest base for carts provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: A first stepped surface is provided on the end surface of a bent end plate 3, and a second stepped surface is provided on the end surface of the second bent end plate 4. The second stepped surface matches the first stepped surface, and this structure replaces the card in the first embodiment. The connection structure makes the installation more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com