Method of making article and products

A technology of objects and manufacturing methods, applied in household components, layered products, other household appliances, etc., can solve problems such as appearance and surface defects, and achieve the effect of good bonding strength and easy forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

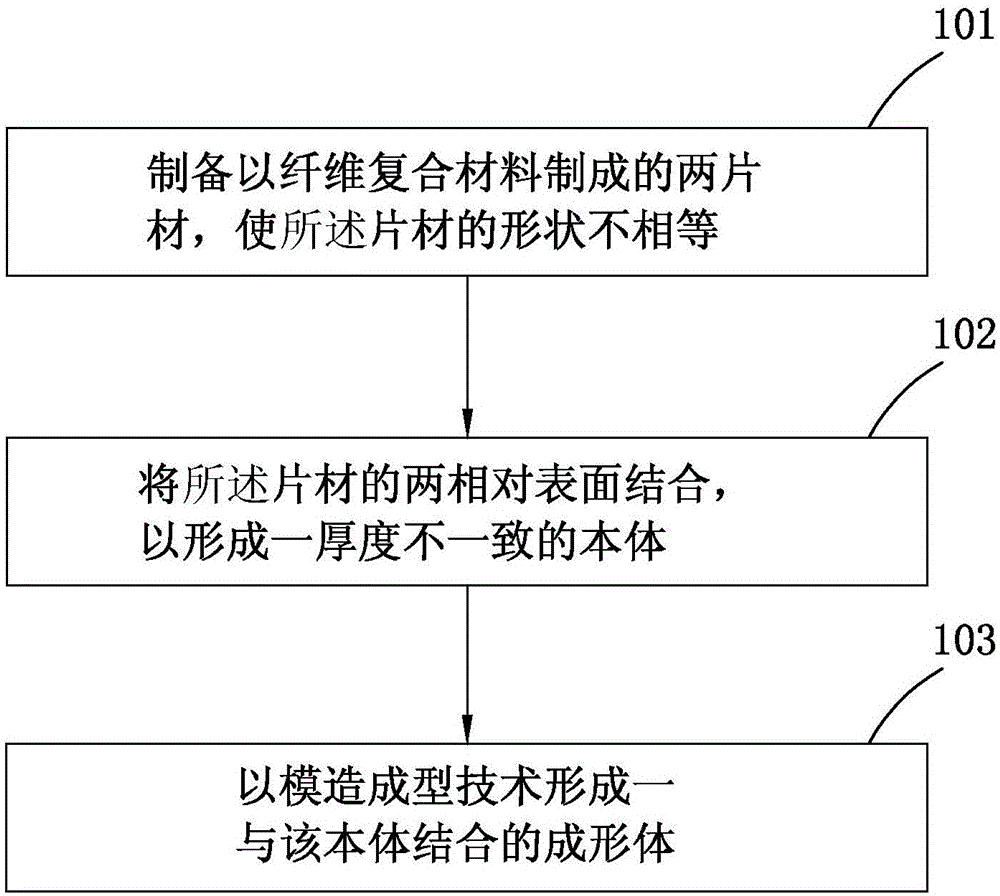

[0045] refer to figure 1 , the first embodiment of the preparation method of the object of the present invention mainly includes the following steps:

[0046] Step 101, preparing two sheets made of fiber composite material, so that the shapes of the sheets are unequal;

[0047] Step 102, combining two opposite surfaces of the sheets to form a body with non-uniform thickness; and

[0048] Step 103, forming a molded body combined with the main body by molding technology.

[0049] The aforementioned fiber composite material is a general fiber-reinforced polymer composite material, which can be purchased from commercially available products. In this embodiment, the fiber composite material whose base material is thermoplastic is selected. The specific steps are further explained as follows:

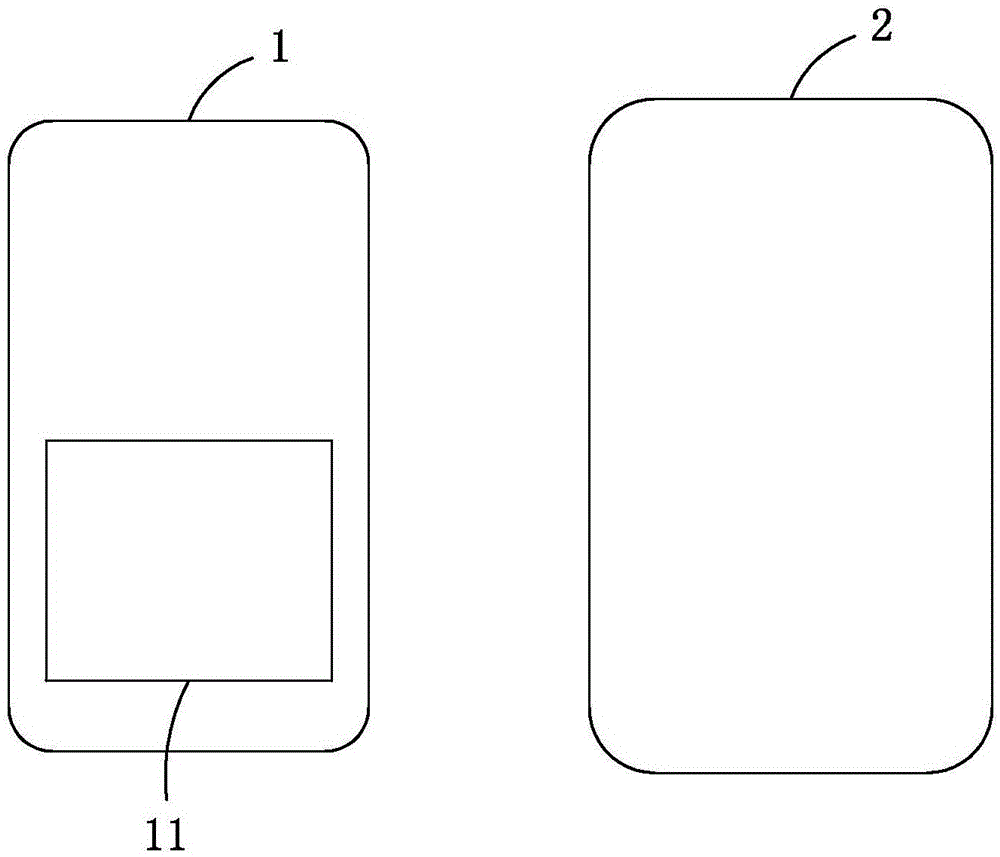

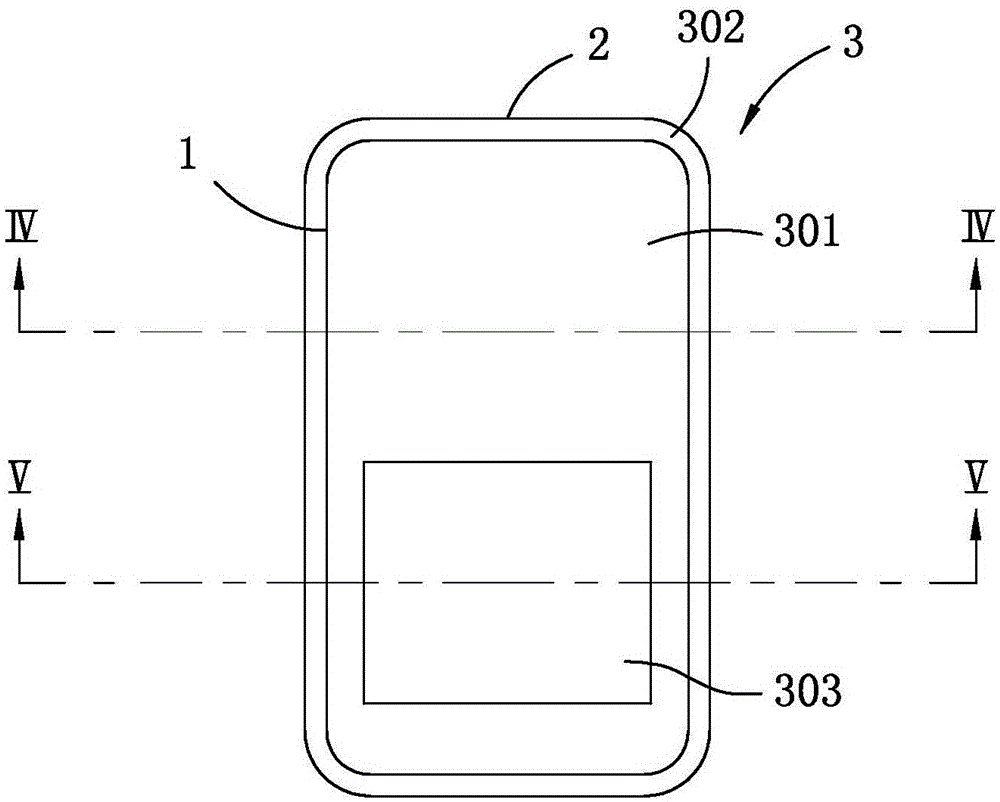

[0050] refer to figure 2 , in step 101, two sheets made of fiber composite materials with unequal shapes are cut out according to requirements, for example figure 2 The first sheet 1 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com