A kind of reed stalk aluminum plate composite plate and preparation method thereof

A composite plate and reed rod technology, which is applied in the field of reed rod aluminum plate composite board and its preparation, can solve the problems of reed rod strength and toughness damage, no product, high price, etc., and achieve structural strength retention, improved bonding performance, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

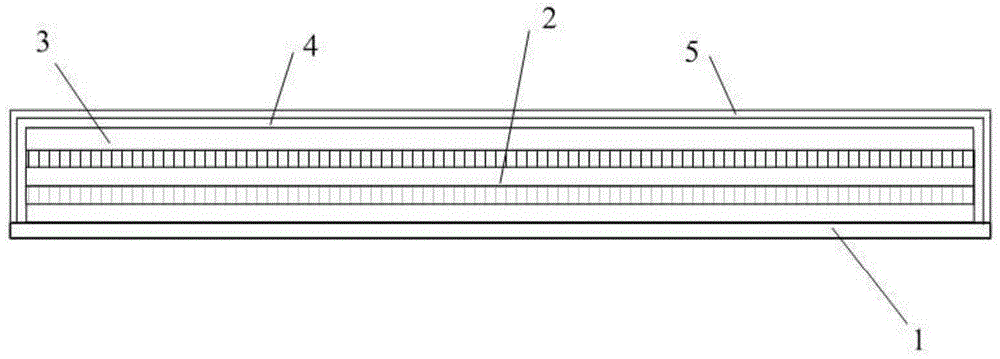

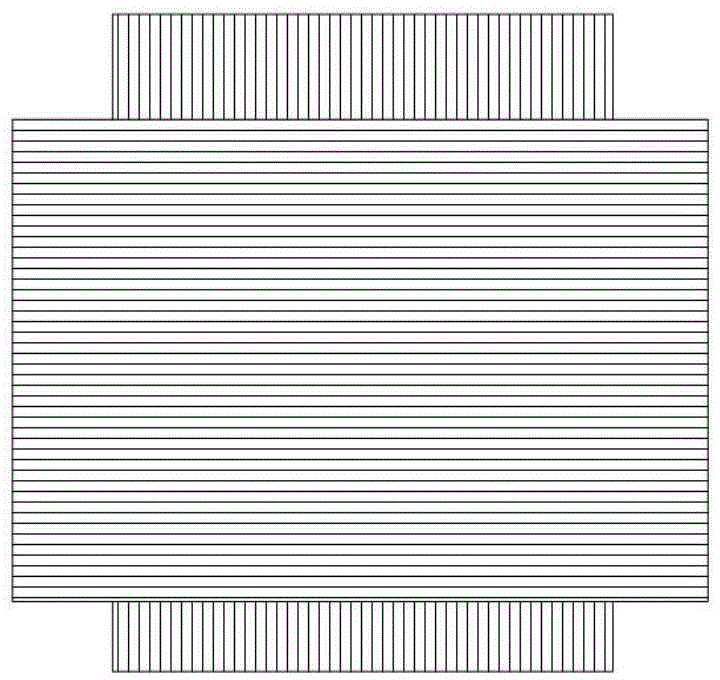

Image

Examples

preparation example Construction

[0028] The method for preparing a reed pole aluminum composite board provided by the present invention has the following specific steps:

[0029] (1) The preparation steps of reed bark include:

[0030] (1a) After removing the leaves of the original reed stalk, select the middle part of the original reed stalk and cut it into sections according to the required length;

[0031] (1b) The reed rod obtained in step (1a) is subjected to surface modification treatment to destroy the silicified and resinous structure of the reed rod surface and improve the adhesion of the reed rod. The surface modification treatment is to The reed rods are soaked in hot water at 90-100°C for 1 to 1.5 hours, or placed in a NaOH solution with a concentration of 0.5 to 1% and a temperature of 40-50°C for 0.5 to 1 hour;

[0032] (1c) After the reed stems treated in step (1b) are dried to a moisture content of 6-8%, the reed stems are gathered side by side, and then rolled and flattened along the stem direction o...

Embodiment 1

[0047] The steps for preparing the reed pole aluminum composite material are as follows:

[0048] (1) The preparation steps of reed bark include:

[0049] (1a) After removing the leaves of the original reed stalk, select the middle part of the original reed stalk and cut it into 60mm sections;

[0050] (1b) The reed rod obtained in step (1a) is subjected to surface modification treatment to destroy the silicified and resinous structure of the reed rod surface and improve the adhesion of the reed rod. The surface modification treatment is to The reed rods are soaked in hot water at 90°C for 1.5 hours, or placed at a concentration of 0.5%;

[0051] (1c) After the reed stems processed in step (1b) are dried to a moisture content of 6%, the reed stems are gathered side by side, and then rolled and flattened along the stem direction of the reed stems;

[0052] (1d) Coating urea-formaldehyde resin glue on the reed stem skin obtained in step (1c);

[0053] (1e) The reed rods coated with the ad...

Embodiment 2

[0064] The steps for preparing the reed pole aluminum composite material are as follows:

[0065] (1) The preparation steps of reed bark include:

[0066] (1a) After removing the leaves of the original reed stalk, select the middle part of the original reed stalk and cut it into 60mm sections;

[0067] (1b) The reed rod obtained in step (1a) is subjected to surface modification treatment to destroy the silicified and resinous structure of the reed rod surface and improve the adhesion of the reed rod. The surface modification treatment is to The reed rods were soaked in NaOH solution at a temperature of 40°C for 1 hour;

[0068] (1c) After the reed stems processed in step (1b) are gathered side by side, they are rolled and flattened along the stem direction of the reed stems;

[0069] (1d) Coating urea-formaldehyde resin glue on the reed stem skin obtained in step (1c);

[0070] (1e) The reed rods coated with the adhesive in step (1d) are gathered side by side and hot pressed into a reed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com