Manufacturing process of light heat insulation refractory castable

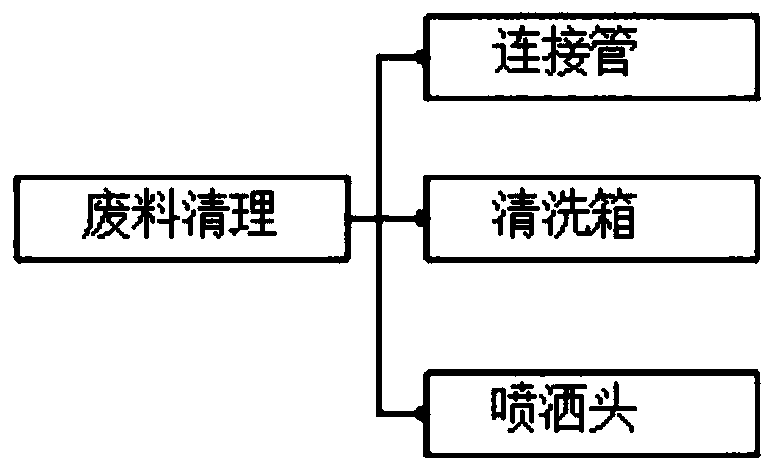

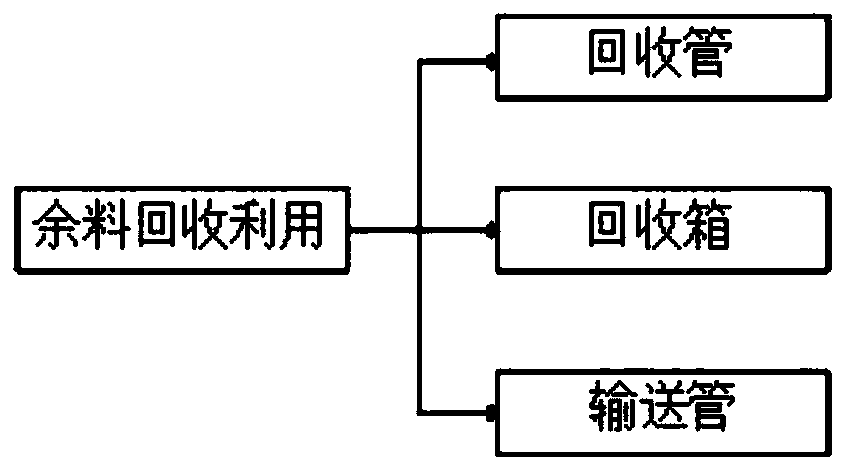

A technology of refractory castables and manufacturing process, which is applied in the field of castables, can solve the problems that the remaining materials cannot be recycled, the mixer is not cleaned sufficiently, and the effect of avoiding waste is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

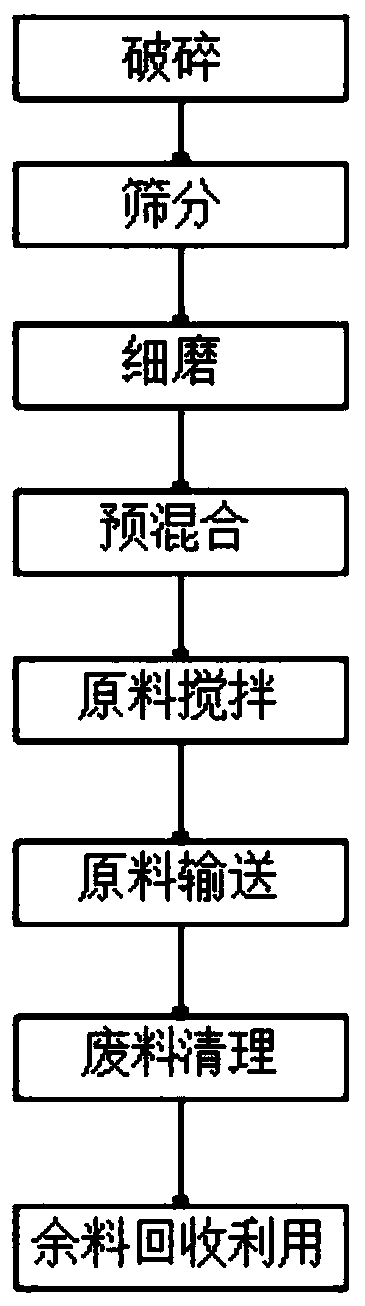

[0030] A manufacturing process of a lightweight heat-insulating refractory castable, comprising the following steps:

[0031] S1. Crushing treatment. Put the bulky raw materials into the jaw crusher for crushing, and at the same time, carry out intermediate crushing and fine crushing of the crushed raw materials. The equipment is cone crusher, roller crusher and dry mill. After crushing and crushing treatment to obtain powdery refractory raw materials;

[0032] S2, screening treatment, put the pulverized refractory raw material into the screening device, and the screening device screens it, divides the refractory raw material into granular raw materials with different particle sizes according to the particle size, and the screening device is divided into fixed inclined screen device and electromagnetic vibrating screen to produce granular refractory raw materials;

[0033] S3, fine grinding treatment, put the sieved granular raw material into the grinding device, and the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com