Clothes treatment equipment and control method thereof

A technology of clothes processing equipment and a control method, which is applied to the control device of washing machines, other washing machines, household clothes dryers, etc., can solve problems such as poor user experience and long time-consuming drying of clothes, so as to improve drying efficiency and guarantee safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

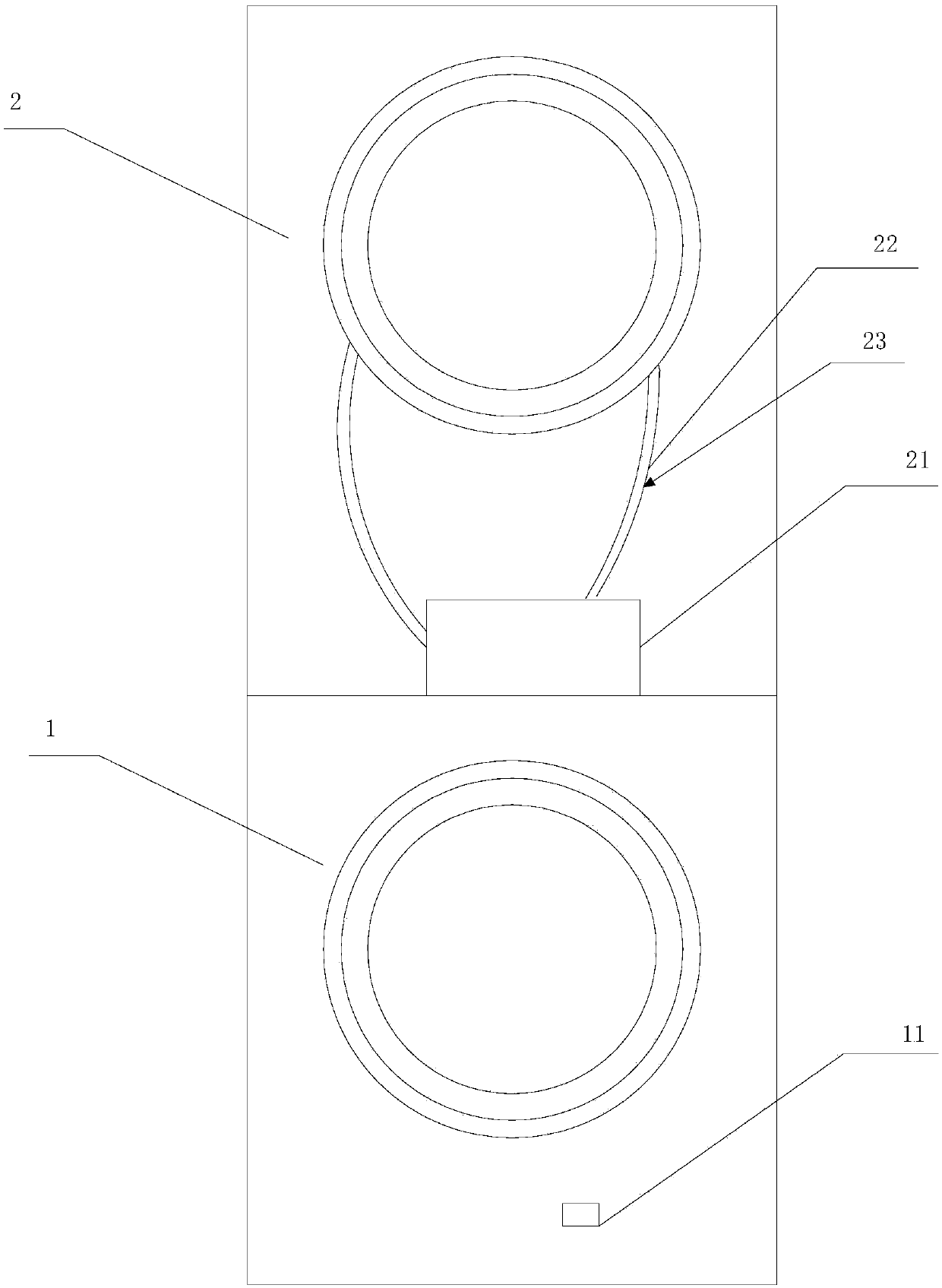

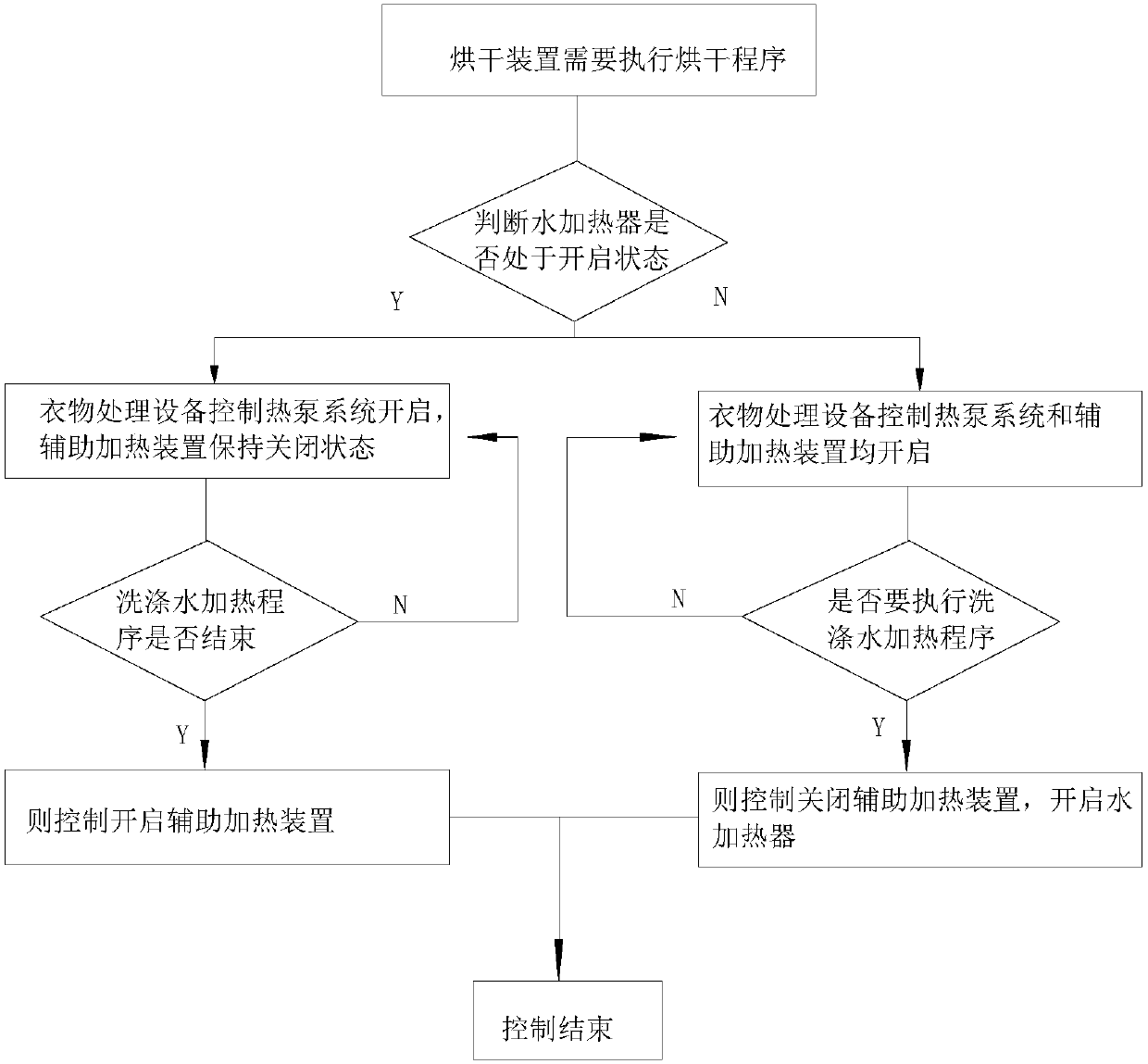

[0049] see figure 1 and figure 2 As shown, this embodiment provides a method for controlling clothes processing equipment. The clothes processing equipment includes a washing device 1 and a drying device 2. The washing device 1 includes a water heater 11 for heating washing water. The described The drying device 2 includes a heat pump system 21 and an auxiliary heating device 22 for heating the drying air. When the washing water heating program and the drying program need to be executed at the same time, the laundry treatment equipment controls the water heater 11, the heat pump system 21, and the auxiliary heating device. The switching and / or adjusting power of the device 22 meets the power requirement of the whole machine of the laundry treatment equipment.

[0050] In the above solution, when the washing water heating program and the drying program need to be executed simultaneously, the laundry treatment equipment controls the water heater 11 of the washing device 1, the...

Embodiment 2

[0083] Embodiment 2 is the same as Embodiment 1 in that the laundry processing equipment also includes a washing device 1 and a drying device 2, the washing device 1 includes a water heater 11 for heating washing water, and the drying device 2 The device 2 includes a heat pump system 21 for heating the drying air and an auxiliary heating device 22. The difference is that the compressor of the heat pump system 21 of the laundry treatment equipment in the second embodiment is an inverter compressor. In actual work, The laundry processing equipment adjusts the power of the whole machine by controlling the working frequency of the frequency conversion compressor. When the washing water heating program and the drying program are executed at the same time, the laundry treatment equipment controls to reduce the frequency of the compressor so that the heat pump system 21 and the auxiliary heating device 22 and the water heater 11 of the washing device 1 are turned on for heating at the...

Embodiment 3

[0086] see figure 1 As shown, the third embodiment provides a clothes processing device adopting the control method in the first embodiment or the second embodiment above, which includes a box body, and a washing device 1 and a drying device 2 are respectively arranged in the box body, and the two are up and down. Set in the box, the washing device 1 includes a water heater 11 for heating the washing water, and the drying device 2 includes a heat pump system 21 and an auxiliary heating device 22 for heating the drying air;

[0087] Preferably, the drying device 2 includes a drying air duct 23, and a circulating fan is arranged in the drying air duct 23 to provide drying air circulation power, and the auxiliary heating device 22 is installed on the drying air The heating wire in the channel, or the auxiliary heating device 22 is a heating wire coated on the pipeline connecting the compressor of the heat pump system 21 and the condenser. The heating wire is heated to increase th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com