Clothes processing device and control method thereof

A technology of clothes processing equipment and a control method, which is applied in the direction of washing machine control devices, other washing machines, household clothes dryers, etc., and can solve the problems of the all-in-one machine working power exceeding the rated power, inconvenient use, and excessive current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

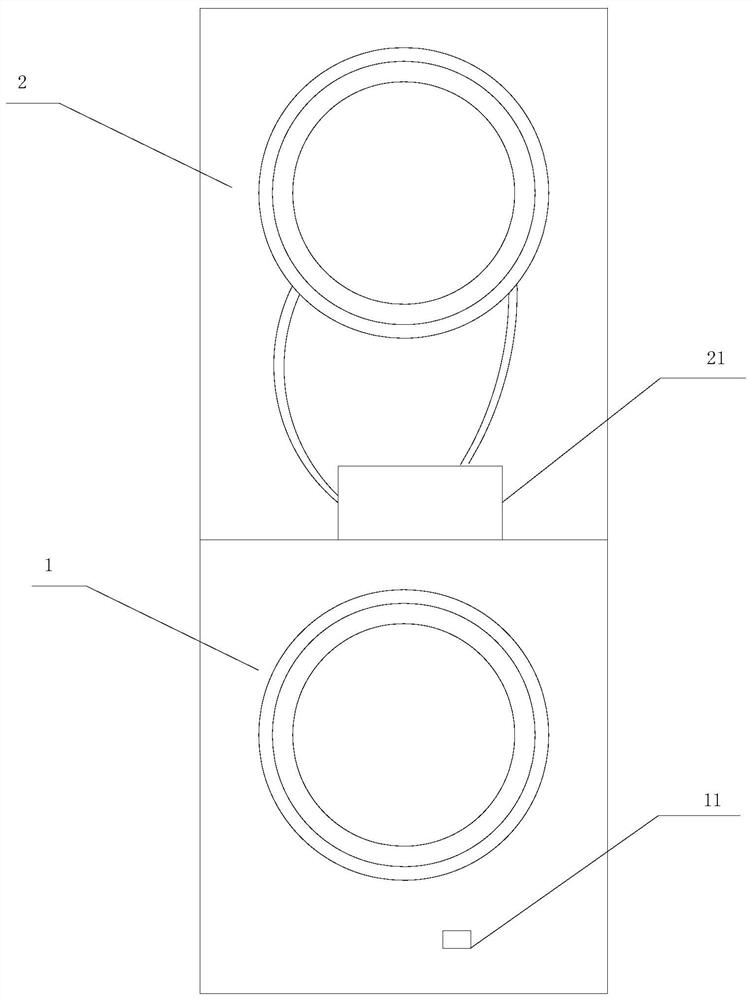

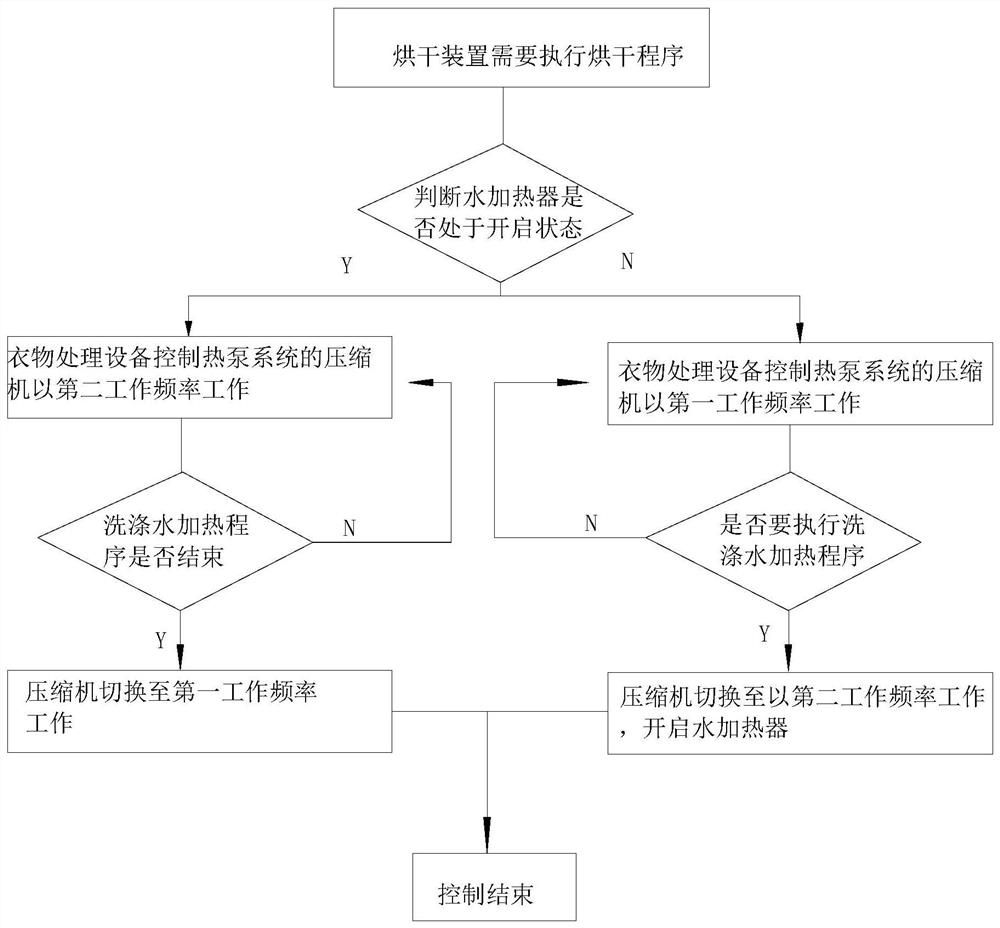

[0046] see figure 1 and figure 2 As shown, the first embodiment provides a method for controlling clothes processing equipment. The clothes processing equipment includes a washing device 1 and a drying device 2. The washing device 1 includes a water heater 11 for heating washing water. The drying device 2 includes a heat pump system 21 for heating the drying air. When the washing water heating program and the drying program need to be executed at the same time, the laundry treatment equipment controls the water heater 11 and the heat pump system 21 not to work at the same time, or adjusts the water The power of the heater 11 and / or the heat pump system 21 enables both to work simultaneously.

[0047] In the above solution, when the washing water heating program and the drying program need to be executed simultaneously, the laundry treatment equipment controls the water heater 11 of the washing device 1 and the heat pump system 21 of the drying device 2 to not work at the sam...

Embodiment 2

[0068] The difference between the second embodiment and the first embodiment is that in the second embodiment, the heat pump system 21 includes a fixed-frequency first compressor and a second compressor, and the operating frequency of the first compressor is higher than that of the second compressor. Working frequency, when the washing water heating program and the drying program need to be executed at the same time, the clothes treatment device controls the operation of the second compressor, and when only the drying program is performed, the clothes treatment device controls the operation of the first compressor.

[0069] In the above solution, the power of the heat pump system 21 is adjusted by switching the operation of the first compressor and the second compressor, so that the heat pump system 21 and the water heater 11 can work at the same time. The high first compressor works, which is beneficial to improve the drying efficiency.

[0070] Preferably, the laundry proces...

Embodiment 3

[0074] The difference between Embodiment 3 and Embodiment 1 and Embodiment 2 is that the water heater 11 is provided with different heating power, and the power of the water heater 11 is adjusted by the laundry treatment equipment so that the heat pump system 21 and the water heater 11 It can work at the same time, or the laundry treatment equipment adjusts the working frequency of the water heater 11 and the compressor of the heat pump system 21 at the same time, so that both can work at the same time.

[0075] In the above solution, it is also possible to adjust the operating frequency of the water heater 11 to make the water heater 11 and the heat pump system 21 work at the same time, or to adjust the operating frequency of the water heater 11 and the compressor of the heat pump system 21 at the same time, so that the clothes processing equipment Work at rated power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com