Fabricated concrete pavement and self-regulating pavement system

A concrete pavement and concrete technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of long cycle, unfavorable rapid laying, slow construction, etc., to achieve the effect of ensuring driving safety and improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

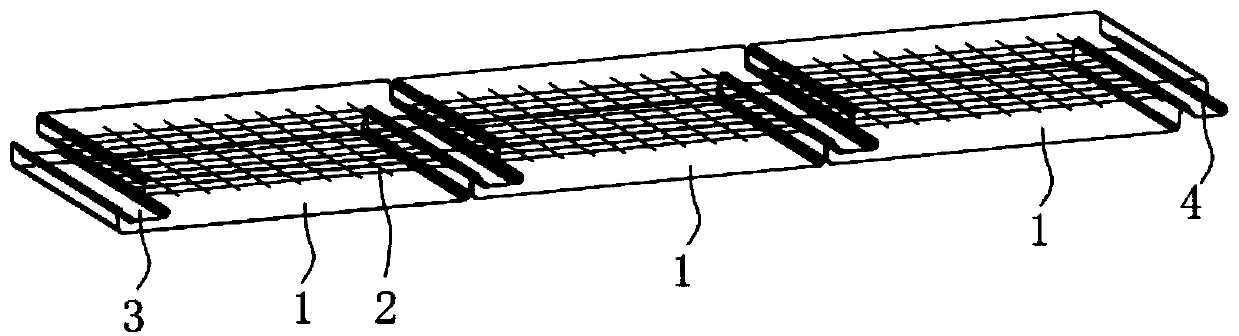

[0031] Such as figure 1 As shown, a prefabricated concrete road surface includes a concrete road slab 1 and a steel bar structure 2 arranged in the concrete road slab 1, a first clamping structure 3 is arranged on one side of the concrete road slab 1, and the other side of the concrete road slab 1 A pair of sides is provided with a second clamping structure 4; the first clamping structure 3 is detachably connected to the second clamping structure 4 on the adjacent concrete road slab 1, and the second clamping structure 4 is connected to the other adjacent The first clamping structure 3 on the concrete road slab 1 is detachably connected.

[0032]In this embodiment, the first clamping structure 3 provided on the concrete road slab 1 is detachably connected with the second clamping structure 4 provided on the adjacent concrete road slab 1; The second clamping structure 4 is detachably connected with the first clamping structure 3 provided on another adjacent connected concrete ...

Embodiment 2

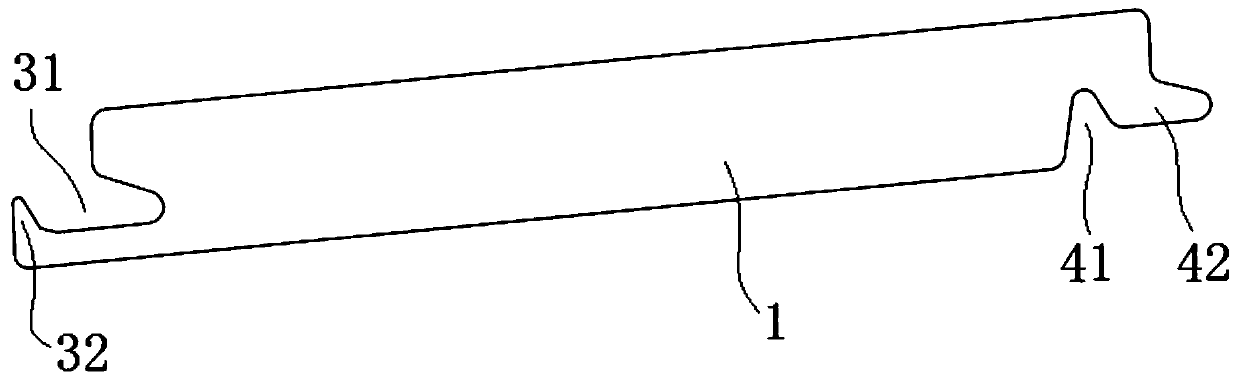

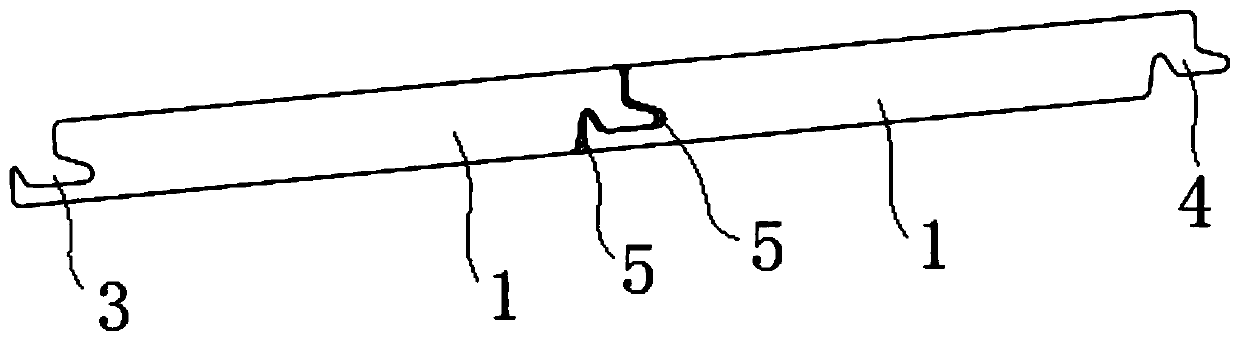

[0034] Such as figure 2 , image 3 As shown, the first clamping structure 3 includes a first slot structure 31 provided on the concrete road slab 1 and a protruding structure 32 formed on the outer edge of the first slot structure 31 . The second clamping structure 4 includes a second slot structure 41 disposed on the bottom surface of the concrete road slab 1 and a wedge structure 42 formed on the outer edge of the second slot structure 41 . In this embodiment, the setting of the first groove structure 31 is to connect with the wedge structure 42 on the concrete road slab 1 adjacent to it, and the protruding structure 32 is to connect to the concrete road slab adjacent to the other side. The second slot structure 41 on the board 1 is connected. The second slot structure 41 is to connect with the protruding structure 32 on the adjacent concrete road slab 1, and the wedge structure 42 is to connect to the first groove on the other side of the adjacent concrete road slab 1. ...

Embodiment 3

[0038] if Figure 4 As shown, the difference from Embodiment 2 is that the first groove structure 31 is provided with an anti-off structure 6 on the side away from the protruding structure 32 , and the upper end surface of the anti-off structure 6 is flush with the upper end surface of the concrete road slab 1 . In this embodiment, the setting of the anti-off structure 6 is to ensure the reliability of the connection between the first slot structure 31 and the wedge structure 42. The first slot on the concrete road slab 1 adjacent to the wedge structure 42 is connected When the structure 31 is connected, the anti-off block structure 6 limits the wedge structure 42 in the first slot structure 31, which prevents the wedge structure 42 from breaking away from the first slot structure 31, and ensures that the wedge structure 42 is compatible with the first slot structure. The slotted structure 31 is connected more stably and reliably.

[0039] Wherein, when the wedge structure 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com