Anti-loosening subway rail nut

An anti-loosening and subway technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of low tightening efficiency and inconvenient use, and achieve the effect of improving tightening efficiency, good anti-loosening effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

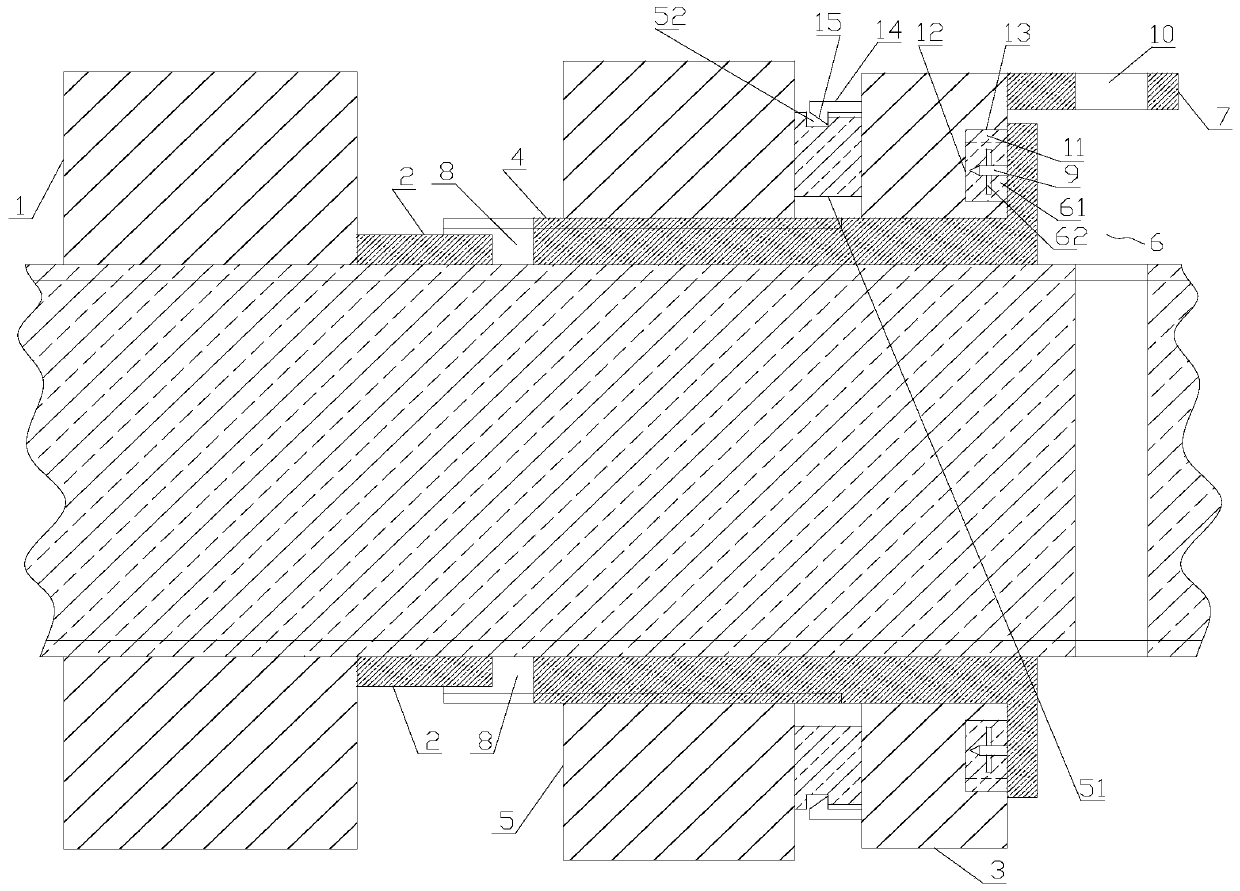

[0019] refer to figure 1 , an anti-loosening subway track nut of the present invention, comprising a first nut body 1, several insert bodies 2, a connecting body 3, a T-shaped sleeve body 4, a second nut body 5, an annular body 6, a connecting protrusion 7, Several insertion slots 8 and some fixing nails 9, the rear end of the first nut body 1 is provided with an insertion body 2, and the front end of the small diameter section of the T-shaped sleeve body 4 is provided with an insertion body 2 one by one. Corresponding to and matched with the insertion slot 8, the small diameter section of the T-shaped sleeve body 4 is sequentially sleeved with the second nut body 5 and the connecting body 3 from front to back, and the small diameter of the T-shaped sleeve body 4 The section is provided with an external thread that matches the second nut body 5, and the receiving groove 12 at the rear end of the connecting body 3 is provided with an annular body 6, and the rear end edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com