Method for producing pharmaceutical grade sodium dehydroacetate by membrane filtration

A technology of sodium dehydroacetate and dehydroacetic acid, applied in the direction of organic chemistry and the like, can solve the problems of high investment, high production cost, large plant area, etc., and achieves the effects of good filtering effect, easy purification and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

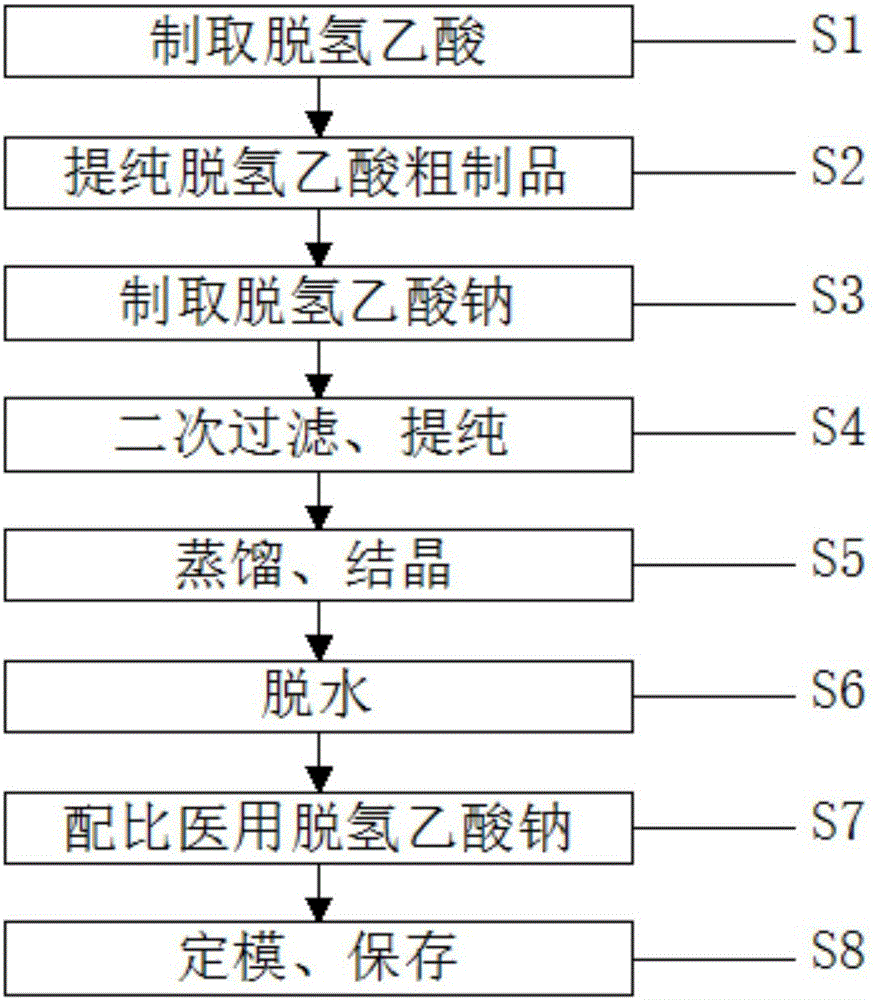

[0024] see figure 1 , the present invention provides a kind of technical scheme: a kind of method of membrane filtration manufactures pharmaceutical grade sodium dehydroacetate, the steps of the method for this membrane filtration manufacture pharmaceutical grade sodium dehydroacetate are as follows:

[0025] S1: Preparation of dehydroacetic acid: material: ethyl acetoacetate, put ethyl acetoacetate in a flask, add water to the flask, stir until ethyl acetoacetate is completely dissolved in water, heat the flask on an alcohol lamp, To obtain dehydroacetic acid, put 5 parts of ethyl acetoacetate in a flask, add 100 parts of water to the flask, place the flask on an alcohol lamp and heat for 2-2.5 hours to obtain solid dehydroacetic acid;

[0026] S2: Purify the crude product of dehydroacetic acid: put the dehydroacetic acid produced in step S1 in a clean beaker, add an inert solvent into the beaker, heat and stir the beaker, and filter the solution in the beaker to remove impur...

Embodiment 2

[0034] A method for membrane filtration to manufacture pharmaceutical grade sodium dehydroacetate, the membrane filtration method for manufacturing pharmaceutical grade sodium dehydroacetate is as follows:

[0035] S1: Preparation of dehydroacetic acid: material: ethyl acetoacetate, put ethyl acetoacetate in a flask, add water to the flask, stir until ethyl acetoacetate is completely dissolved in water, heat the flask on an alcohol lamp, To obtain dehydroacetic acid, the specific steps for preparing dehydroacetic acid are: put 5 parts of ethyl acetoacetate in a flask, add 100 parts of water to the flask, place the flask on an alcohol lamp and heat for 2.25 hours to obtain Solid dehydroacetic acid;

[0036]S2: Purify the crude product of dehydroacetic acid: put the dehydroacetic acid produced in step S1 in a clean beaker, add an inert solvent into the beaker, heat and stir the beaker, and filter the solution in the beaker to remove impurities using a filter sieve Finally, the ...

Embodiment 3

[0044] A method for membrane filtration to manufacture pharmaceutical grade sodium dehydroacetate, the membrane filtration method for manufacturing pharmaceutical grade sodium dehydroacetate is as follows:

[0045] S1: Preparation of dehydroacetic acid: material: ethyl acetoacetate, put ethyl acetoacetate in a flask, add water to the flask, stir until ethyl acetoacetate is completely dissolved in water, heat the flask on an alcohol lamp, To obtain dehydroacetic acid, the specific steps for preparing dehydroacetic acid are: put 5 parts of ethyl acetoacetate in a flask, add 100 parts of water to the flask, place the flask on an alcohol lamp and heat for 2.5 hours to obtain Solid dehydroacetic acid;

[0046] S2: Purify the crude product of dehydroacetic acid: put the dehydroacetic acid produced in step S1 in a clean beaker, add an inert solvent into the beaker, heat and stir the beaker, and filter the solution in the beaker to remove impurities using a filter sieve Finally, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com