Crystallizer vibration generation device with online adjustable amplitude and vibration method of crystallizer vibration generation device

A crystallizer vibration and generating device technology, applied in the field of crystallizer vibration generating devices, can solve the problems of increasing use cost, difficult maintenance, and high use cost, and achieves improvement of surface quality and billet drawing speed, reduction of use cost, and prolongation of service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

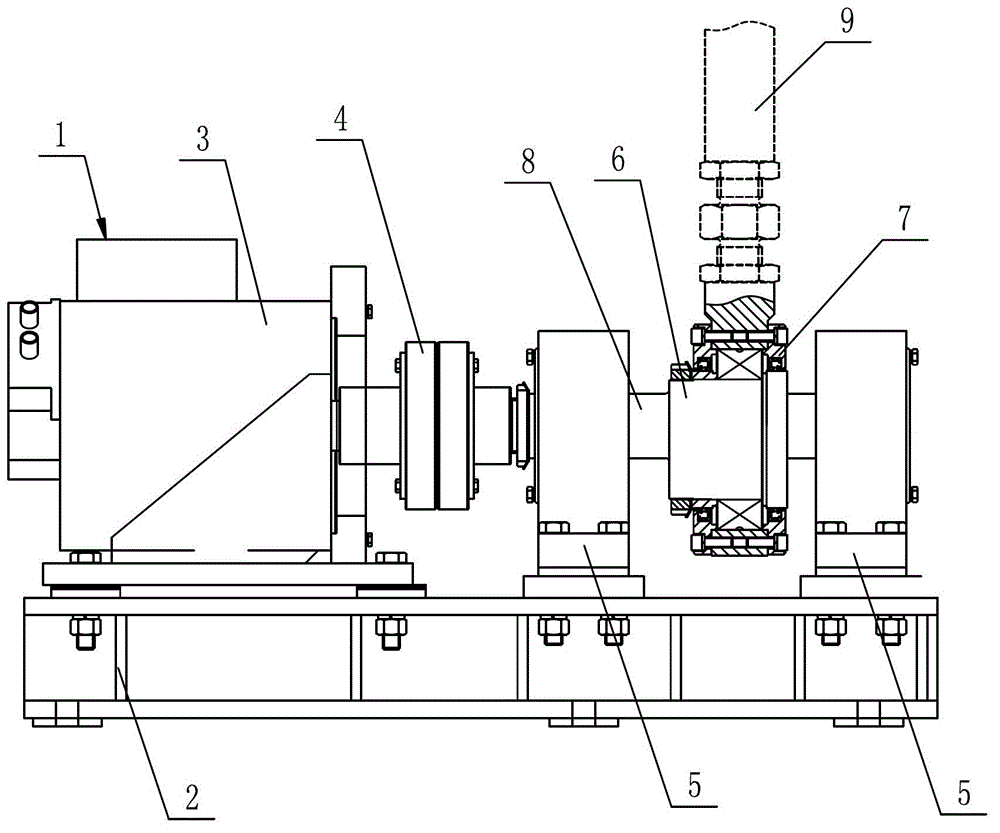

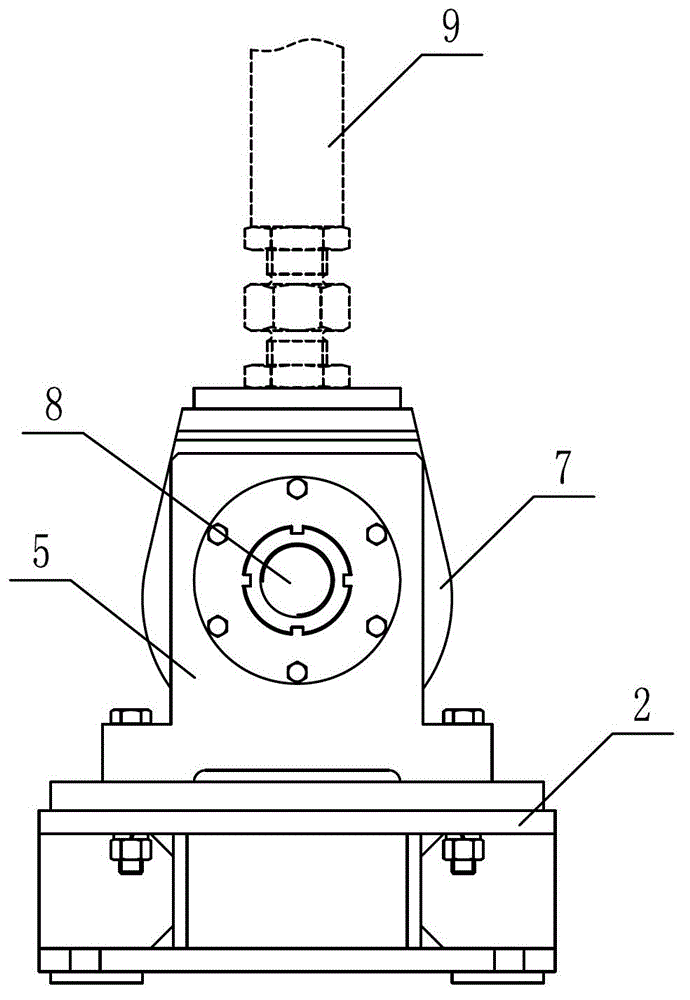

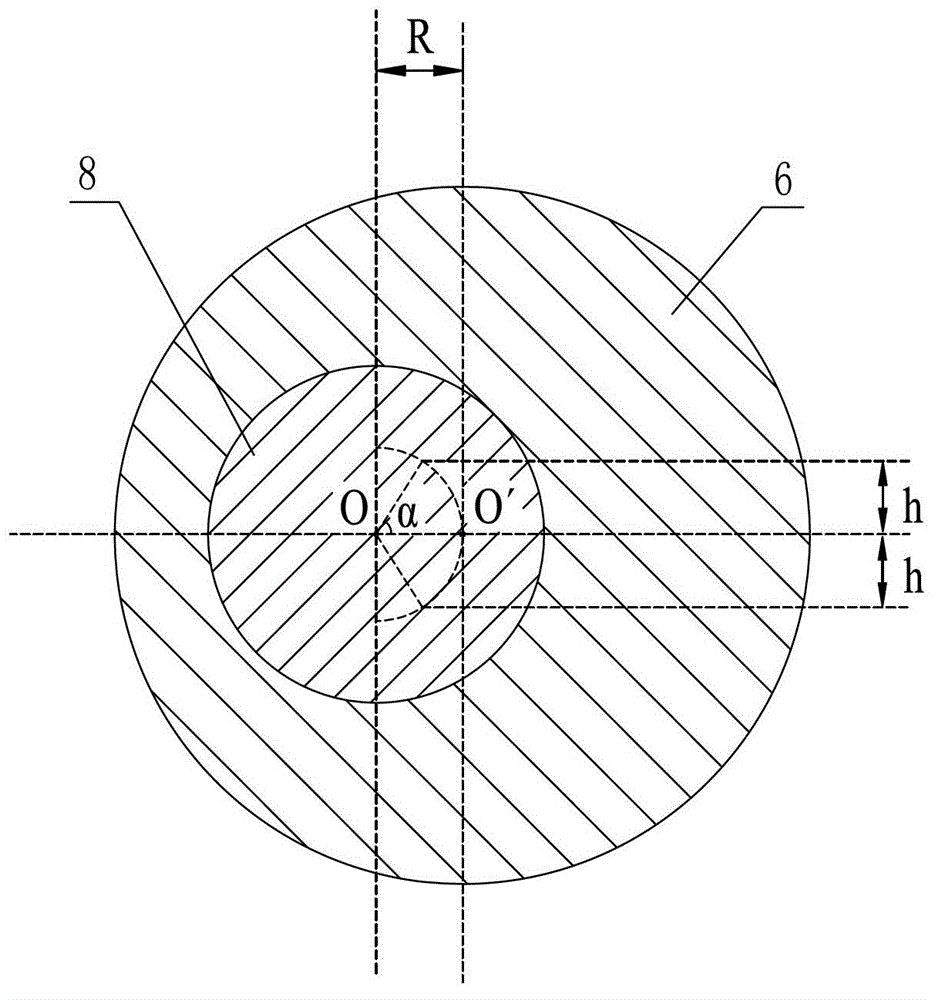

[0027] like Figure 1 to Figure 4 As shown, the crystallizer vibration generating device 1 with online adjustable amplitude of the present invention is used to connect a crystallizer vibration table 10 through a connecting rod 9 . The crystallizer vibration generating device 1 includes a base 2 , and a motor 3 , a shaft coupling 4 , two bearing seats 5 , and an eccentric shaft 6 arranged on the base 2 . A rotating shaft 8 is sleeved inside the eccentric shaft 6, and the rotating shaft 8 is erected between two bearing seats 5. One end of the rotating shaft 8 is connected with the rotating shaft of the motor 3 through a coupling 4, and the coupling 4 is located in one of the Between the bearing housing 5 and the motor 3, the motor 3 is also externally connected to an electrical control system 11 (such as Figure 5 ), in this embodiment, a low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com