An online adjustment mechanism for mechanical seal pretightening force

An adjustment mechanism and mechanical seal technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of low reliability and complicated mechanical seal pre-tightening force adjustment mechanism, and achieve simple and reliable structure and low replacement cost , Realize the effect of online adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be further described in detail and in-depth below in conjunction with the accompanying drawings.

[0022] The invention aims at the research on the performance of the mechanical seal, the size of the pre-tightening force has an important influence on the thickness of the liquid film in the dynamic and static rings of the mechanical seal, and is directly related to the performance and service life of the mechanical seal. The existing adjustment methods are relatively complicated, the reliability is not high, and the application value in the research of the mechanical seal device is not high. In order to solve the problem of online adjustment of mechanical seal pretightening force for static ring compensation, the present invention proposes an online adjustment mechanism for mechanical seal pretightening force.

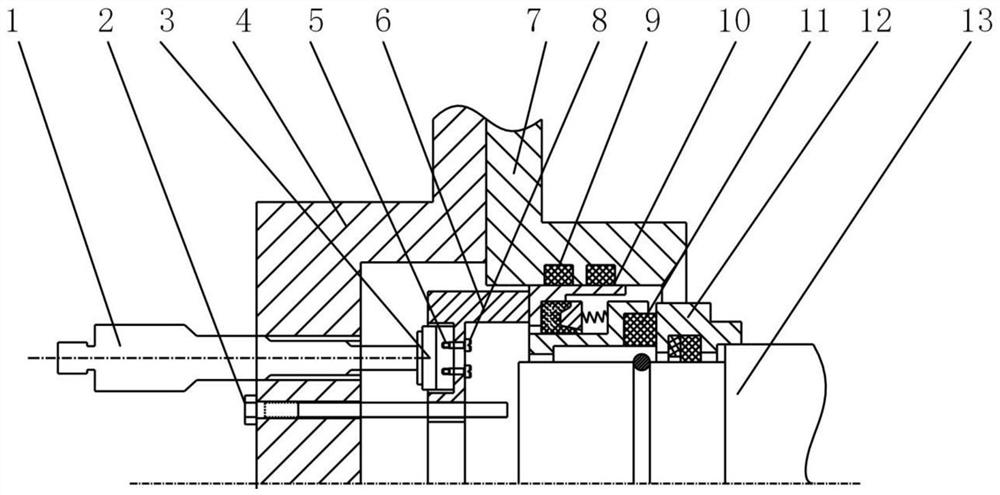

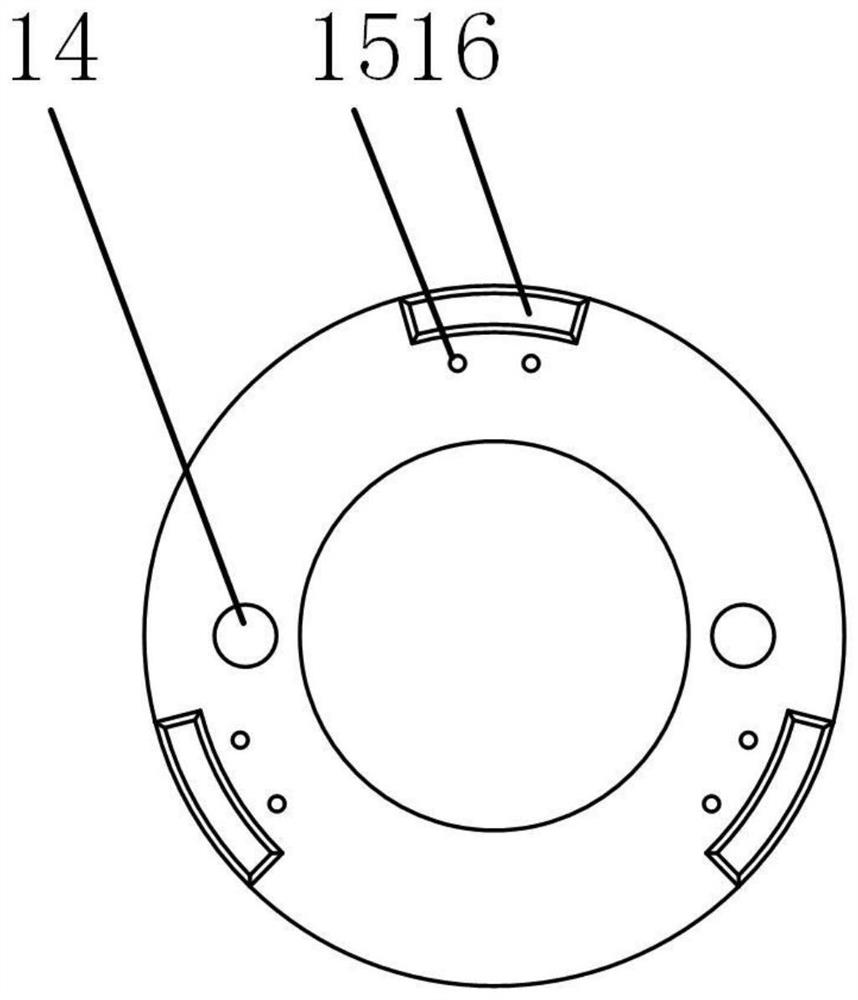

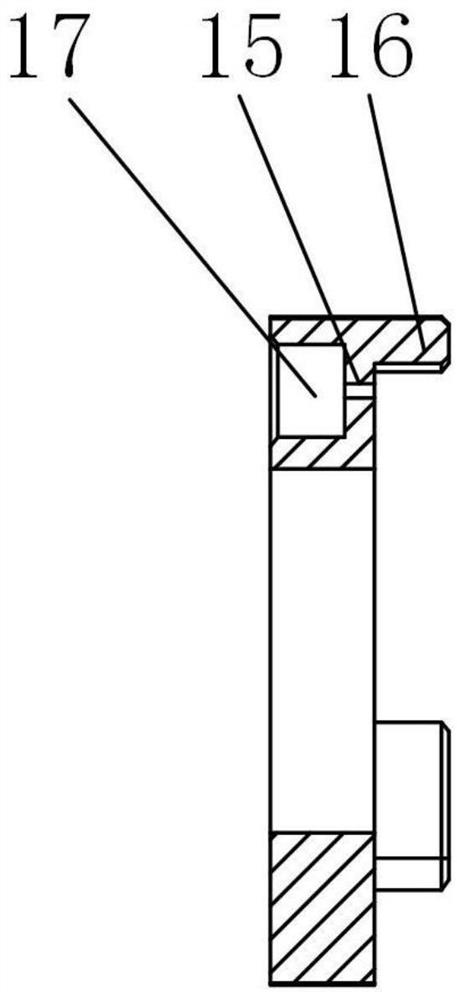

[0023] Such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com