Electrical parameter online adjustable high power pulse forming line and electrical parameter adjustment method

A technology of power pulses and electrical parameters, which is applied in the direction of electric pulse generator circuits, energy storage components to generate pulses, and measurement of resistance/reactance/impedance, etc., which can solve problems such as high production costs, poor environmental adaptability of core parameters, and long development cycles. , to achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

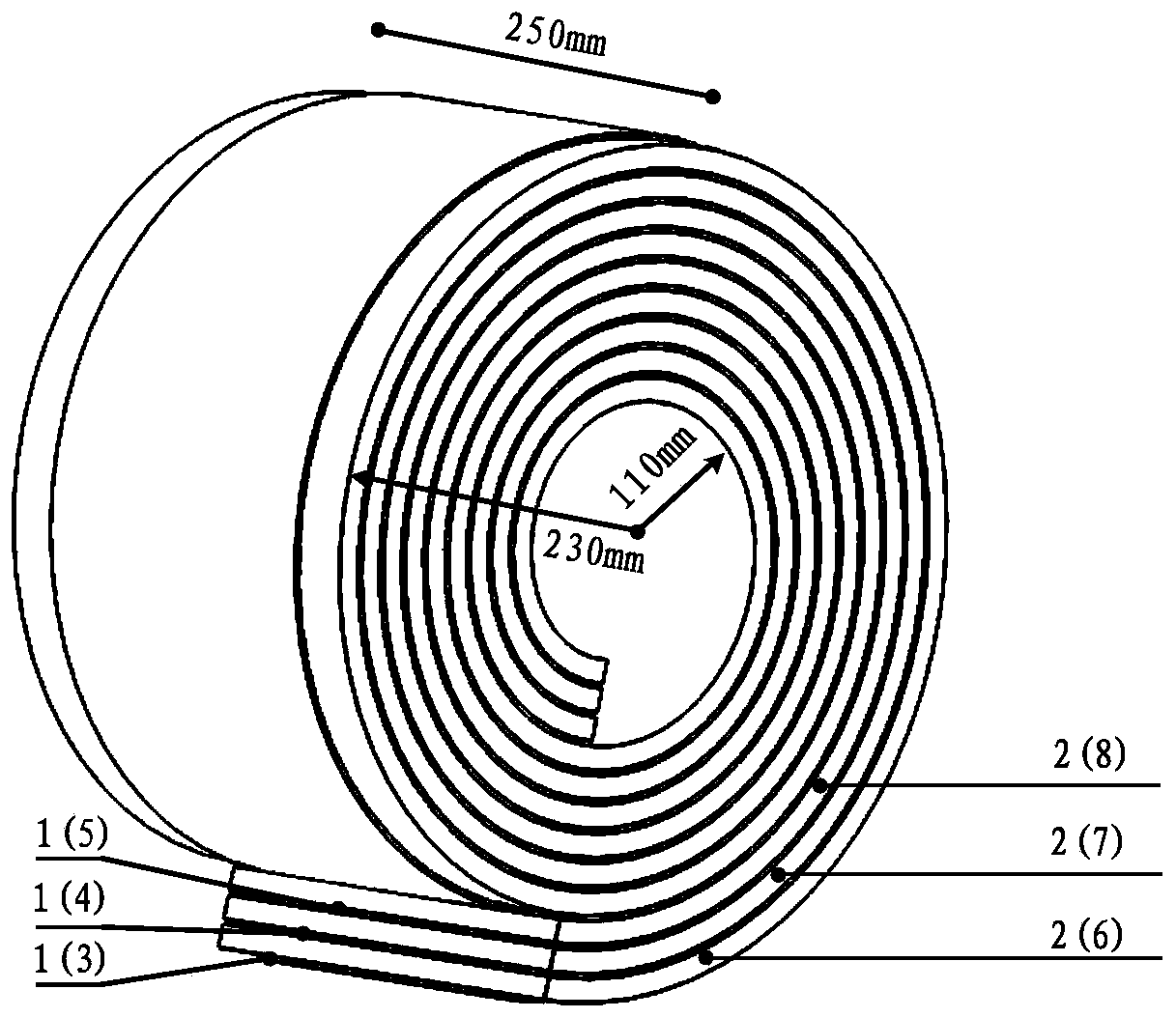

[0053] figure 1 For the background technology Li Song, Qian Baoliang, Yang Hanwu, etc. in the academic paper "An improved rolledstrip pulse forming line" [Song Li, Baoliang Qian, Hanwu Yang, et al. "An improved pulse forming line", (an improved Winding ribbon pulse forming line), Review of Scientific Instruments, Vol.84, 064704, pp: 1-6] reported a winding ribbon pulse forming line based on solid insulating film (DMD film). main

[0054] It consists of metal strip 1 and DMD film 2. Wherein the metal strip 1 is composed of a lower metal strip 3 , a middle metal strip 4 and an upper metal strip 5 . The lower metal strip 3 is made of copper strip with a length of 22000mm, a width of 80mm and a thickness of 0.15mm. The metal strip is wound in a spiral shape with a base circle diameter of 110 mm and a pitch of 5.25 mm. The middle metal strip 4 is made of copper strip, the length is 22000mm, the width is 80mm, and the thickness is 0.15mm. The metal strip is wound in a spiral sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com