Unidirectional drying filter

A filter and drying technology, applied in the field of filters, can solve the problems of high use cost and small circulation, and achieve the effect of increasing circulation and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The "several" mentioned herein refers to a plurality of indeterminate numbers, usually more than two.

[0034] Words such as "first" and "second" mentioned herein are only used to describe two or more structures or components with the same or similar structures, and do not represent any special limitation on the order.

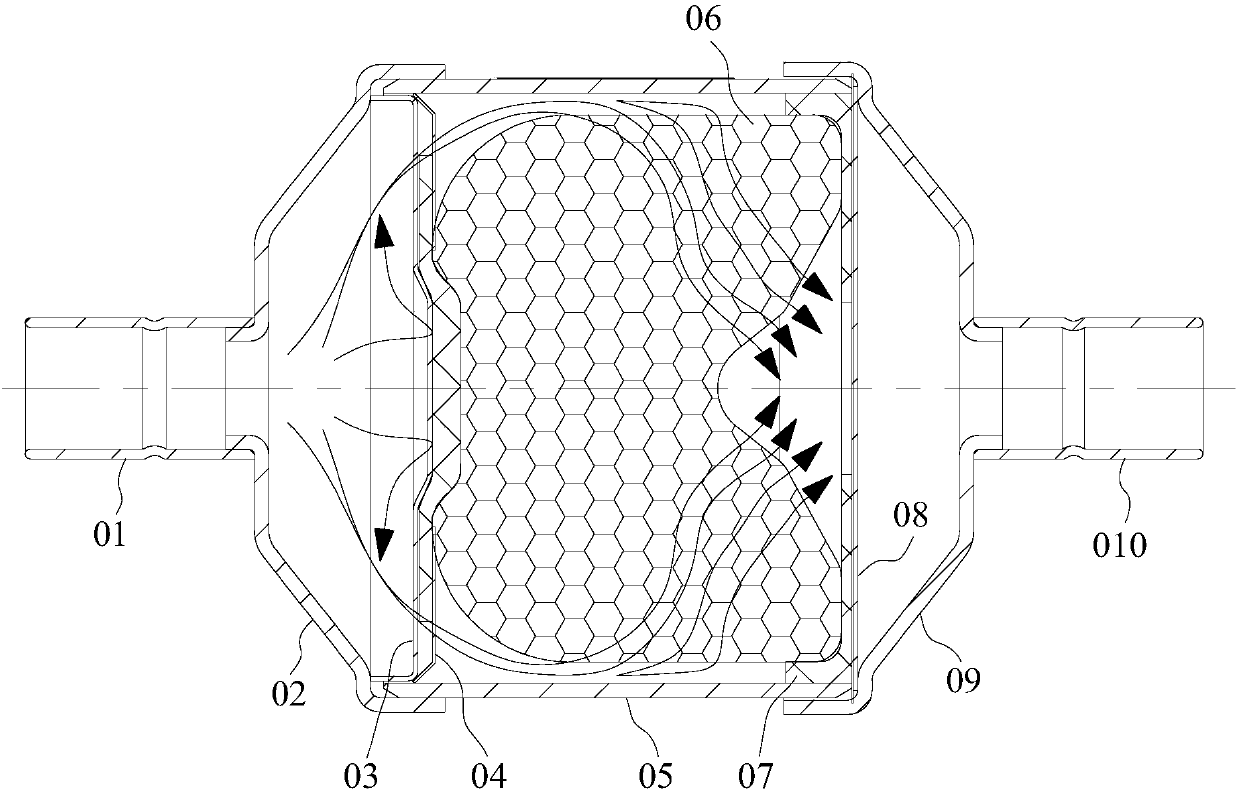

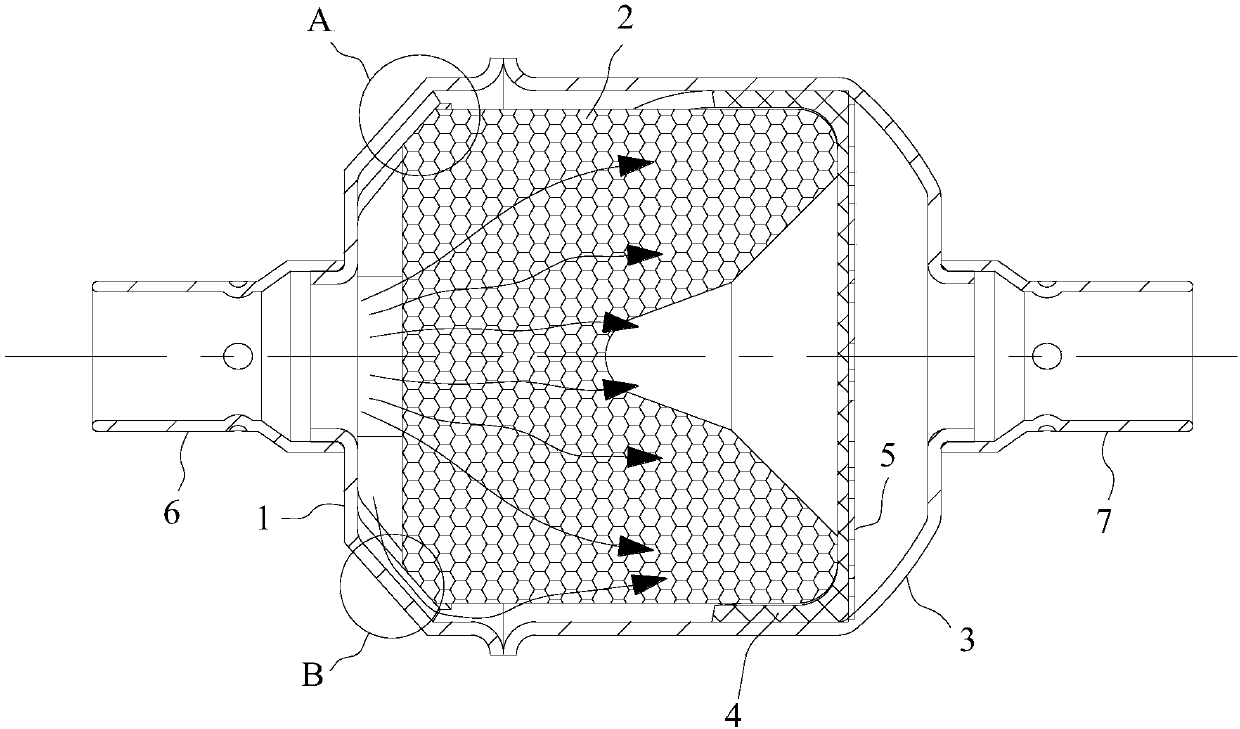

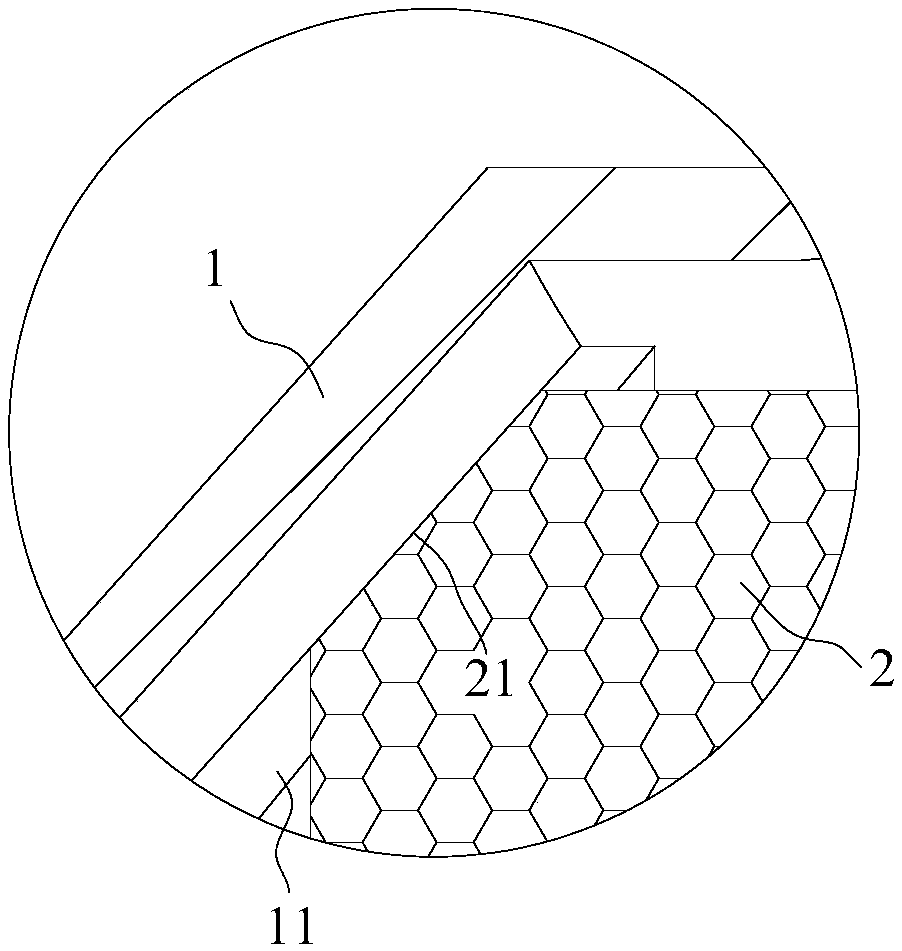

[0035] Please refer to Figure 2-8 , figure 2 It is a structural schematic diagram of a specific embodiment of the one-way drying filter provided by the present invention, image 3 for figure 2 Partial enlarged view of part A in the middle, Figure 4 for figure 2 Partial enlarged view of part B in Figure 5 Schematic diagram of the structure of the inlet end cap, Figure 6 for Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com